High-washing-fastness gold printing paste and preparation method thereof

A technology of washing fastness and bronzing pulp, applied in the field of bronzing pulp, can solve the problems of easy fading after washing, achieve the effect of inhibiting growth and reproduction, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

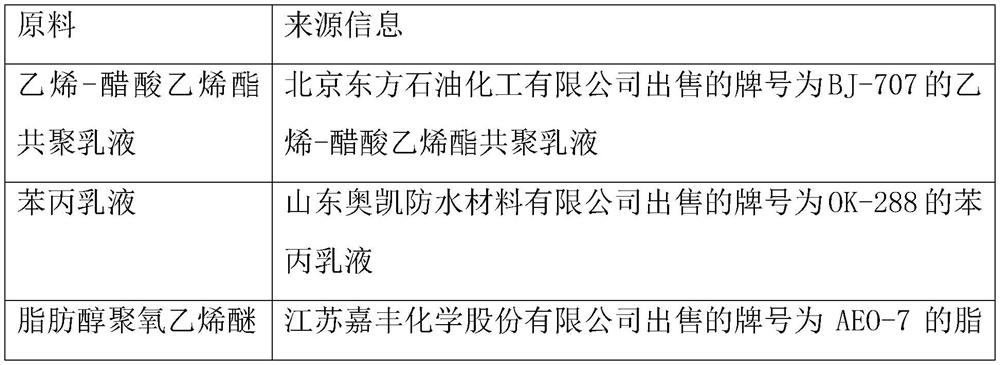

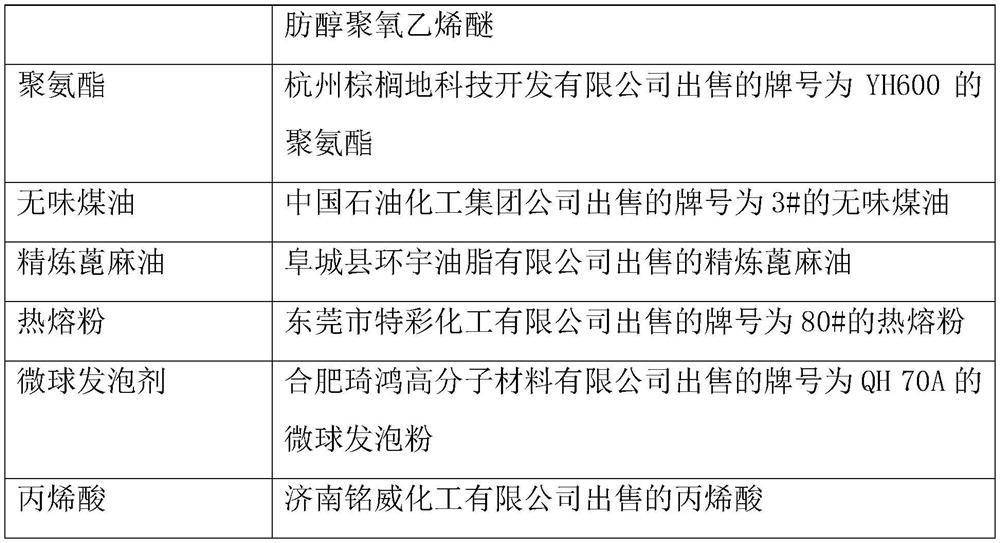

[0079] A bronzing paste with high washing fastness, comprising the following components:

[0080] Ethylene-vinyl acetate copolymer emulsion, styrene-acrylic emulsion, odorless kerosene, microsphere foaming powder, fatty alcohol polyoxyethylene ether, hot-melt powder, preservative, water.

[0081] The preservative is a compound of 5-chloro-2-methylisothiazolin-3-one hydrochloride and 2-methyl-4-isothiazolin-3-one hydrochloride;

[0082] The solid content of the ethylene-vinyl acetate copolymer emulsion is 54%, and the solid content of the styrene-acrylic emulsion is 49%.

[0083] In embodiment 1-4, the input amount (unit Kg) of each component sees table 2 for details

[0084] Table 2

[0085]

[0086]

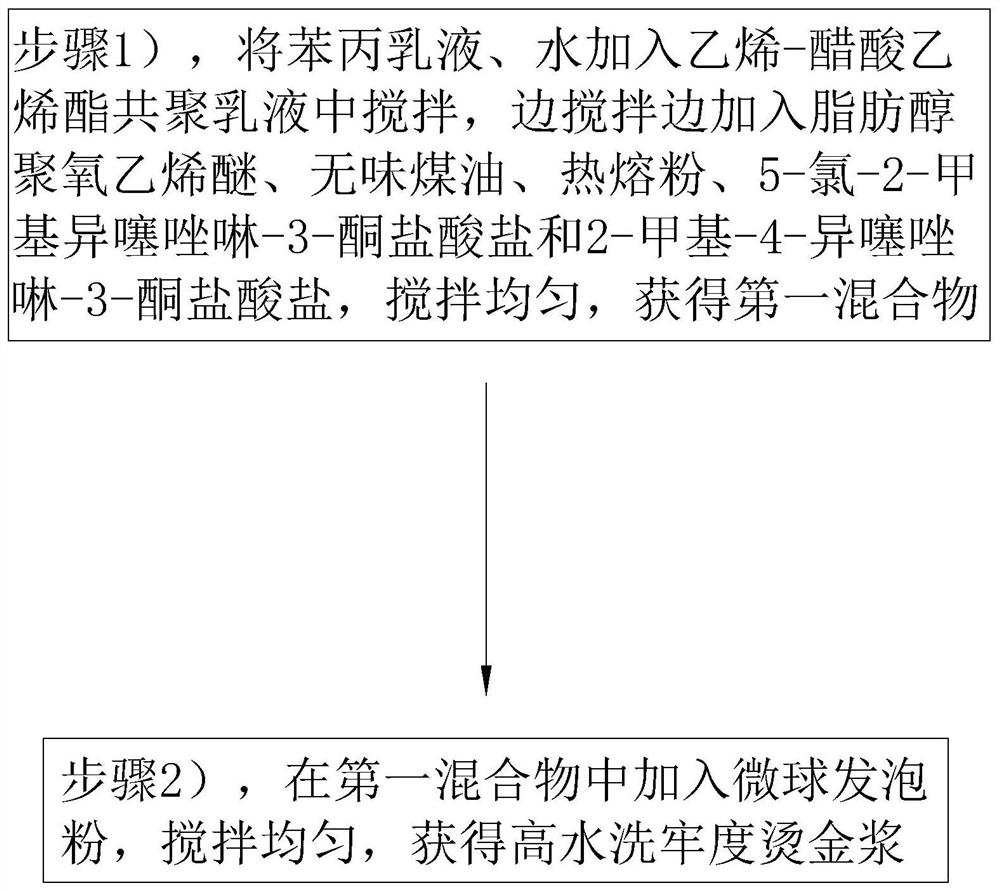

[0087] refer to figure 1 , in embodiment 1-4, the preparation method of bronzing pulp of high washing fastness comprises the following concrete steps:

[0088] Step 1), add styrene-acrylic emulsion and water to ethylene-vinyl acetate copolymer emulsion into the stirrin...

Embodiment 5

[0091] This embodiment discloses a bronzing pulp with high washing fastness:

[0092] The difference with embodiment 2 only lies in:

[0093] The solid content of the ethylene-vinyl acetate copolymer emulsion is 52%, and the solid content of the styrene-acrylic emulsion is 45%.

[0094] In the preparation method of bronzing pulp with high washing fastness:

[0095] Step 1), add fatty alcohol polyoxyethylene ether, odorless kerosene, hot melt powder, 5-chloro-2-methylisothiazolin-3-one hydrochloride and 2-methyl-4-isothiazole while stirring Lin-3-one hydrochloride, keep stirring for 20min.

[0096] Step 2), after adding the microsphere foaming agent, stir for 30 minutes.

Embodiment 6

[0098] This embodiment discloses a bronzing pulp with high washing fastness:

[0099] The difference with embodiment 2 only lies in:

[0100] The solid content of the ethylene-vinyl acetate copolymer emulsion is 55%, and the solid content of the styrene-acrylic emulsion is 50%.

[0101] In the preparation method of bronzing pulp with high washing fastness:

[0102] Step 1), add fatty alcohol polyoxyethylene ether, odorless kerosene, hot melt powder, 5-chloro-2-methylisothiazolin-3-one hydrochloride and 2-methyl-4-isothiazole while stirring Lin-3-one hydrochloride, keep stirring for 40min.

[0103] Step 2), after adding the microsphere foaming agent, stir for 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com