Vacuum grouting device for microbial seepage prevention of jointed rock mass and using method thereof

A grouting device and a technology for cracked rock mass, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of grout diffusion distance in new cracks, unstable and insufficient grouting pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

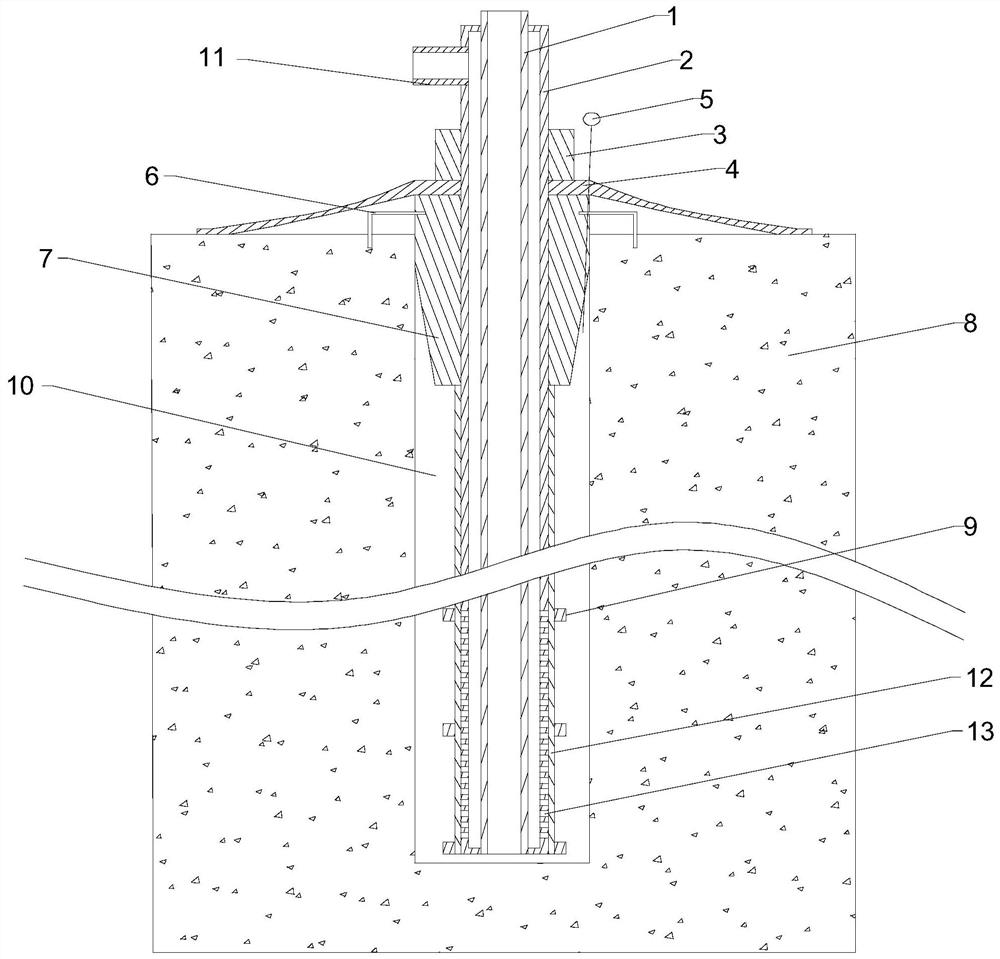

[0040] like Figure 1~2 As shown, this embodiment includes a suction pipe 2 with both ends closed, and a plurality of suction holes 13 are opened on the outer peripheral wall of the lower section along the circumferential direction of the suction pipe 2. Inside the suction pipe 2 A grouting pipe 1 is provided, both ends of the grouting pipe 1 run through both ends of the suction pipe 2, and the upper end of the grouting pipe 1 extends upwards, and the lower end surface of the grouting pipe 1 is flush with the lower end surface of the suction pipe 2 Flat, along the axis of the suction pipe 2, a nut 3, a spacer 4 and a grout stopper 7 are sequentially sleeved on the outer peripheral wall of the upper section from top to bottom. The non-woven fabric 12 covering the suction hole 13 is provided with an exhaust pipe 11 communicating with the inside of the suction pipe 2 on the side wall of the upper section, and the outer diameter of the stopper 7 is the same as the inner diameter o...

Embodiment 2

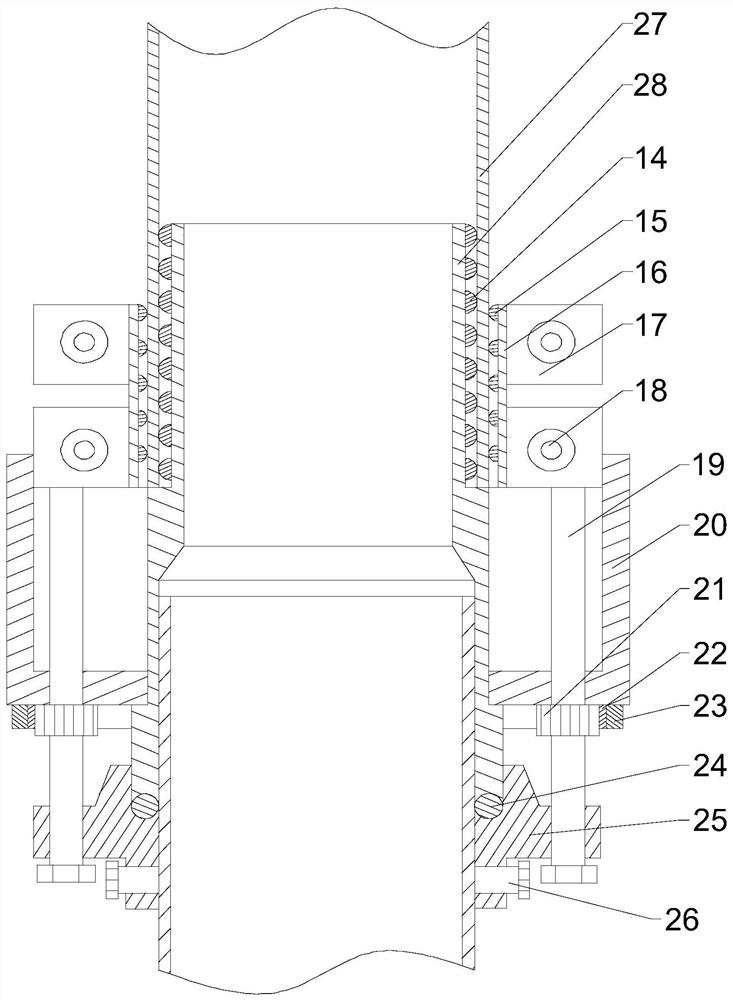

[0046] like figure 2As shown, the connecting assembly described in this embodiment includes a connecting pipe 28, a sleeve 20 is fixed in the middle of the outer peripheral wall of the connecting pipe 28, and an annular recess is formed on the inner peripheral wall of the sleeve 20 along the circumferential direction. groove, and one end of the annular groove is open, a clamp 16 is sleeved on the outer wall of one end of the connecting pipe 28, and the clamp 16 is slidably arranged in the annular groove, and a stopper is provided on the outer wall of the other end of the connecting pipe 28. The back ring 25 has two limit screw holes on the back ring 25 along the axial direction of the connecting pipe 28, and two positioning screw holes on the back ring 25 along the radial direction of the connecting pipe 28. The screw rod 19 After cooperating with the limit screw thread, the activity runs through the closed end of the annular groove and is ball-connected with the clamp 16. Th...

Embodiment 3

[0052] like Figure 1~2 As shown, this embodiment includes the following steps:

[0053] S 1 1. Three grouting holes 10 are drilled, the three grouting devices respectively seal the three grouting holes 10, and the three grouting devices are successively defined as grouting device I, grouting device II, and grouting device III, The three grouting holes 10 are sequentially defined as grouting hole I, grouting hole II, and grouting hole III;

[0054] S 2 . Connect the grouting pipe 1 of the grouting device I and the grouting device III with the cementing solution tank, and connect the grouting pipe 1 of the grouting device II with the bacteria solution tank;

[0055] S 3 1. Turn on the vacuum pump connected to the grouting device I and the grouting device III, draw a vacuum from the grouting hole I and the grouting hole III, and at the same time inject the bacterial solution into the grouting hole II from the grouting device II;

[0056] S 4 . When the water and air separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com