Combination valve group for compressed air treatment for armored vehicles

A technology of compressed air and combined valves, which is applied in the direction of fluid pressure actuation system components, servo motor components, fluid pressure actuation devices, etc., which can solve the problem that the amount of air leakage cannot be ignored, the space occupied by the pipeline is large, and the reliability of the system is affected and other problems, to achieve the effect of reducing assembly cost, simple structure and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

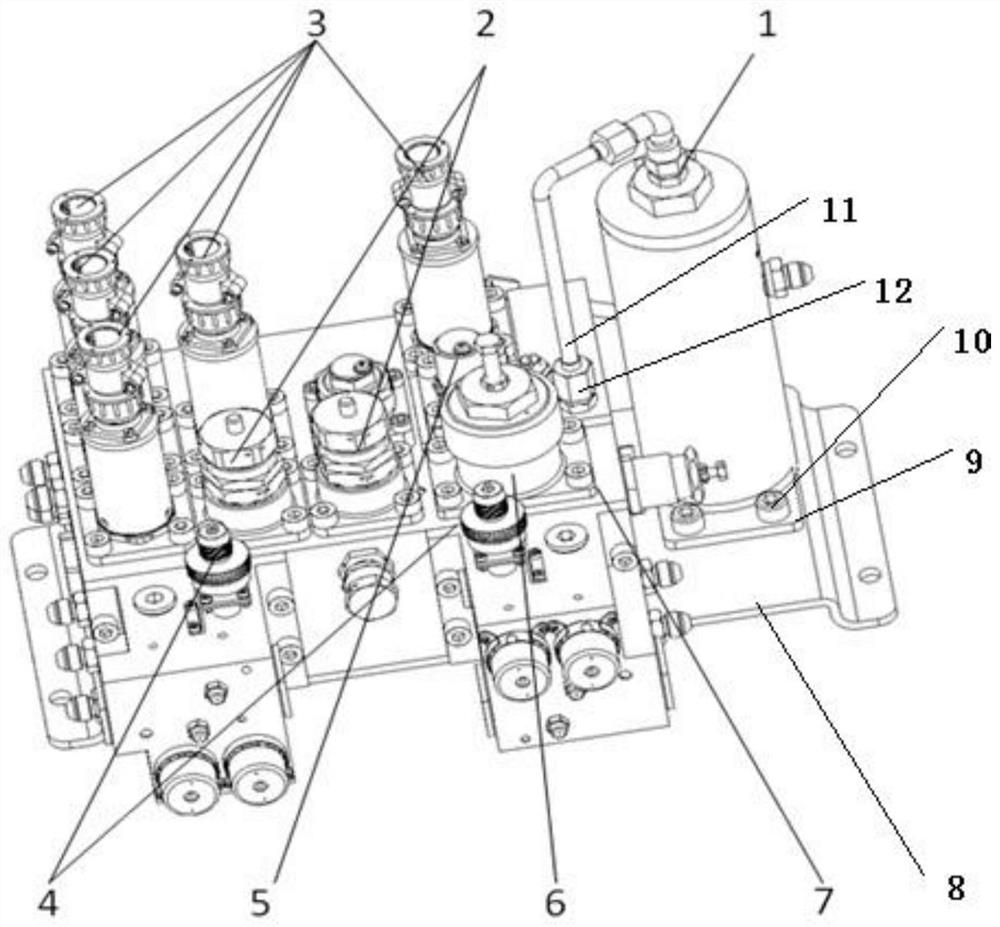

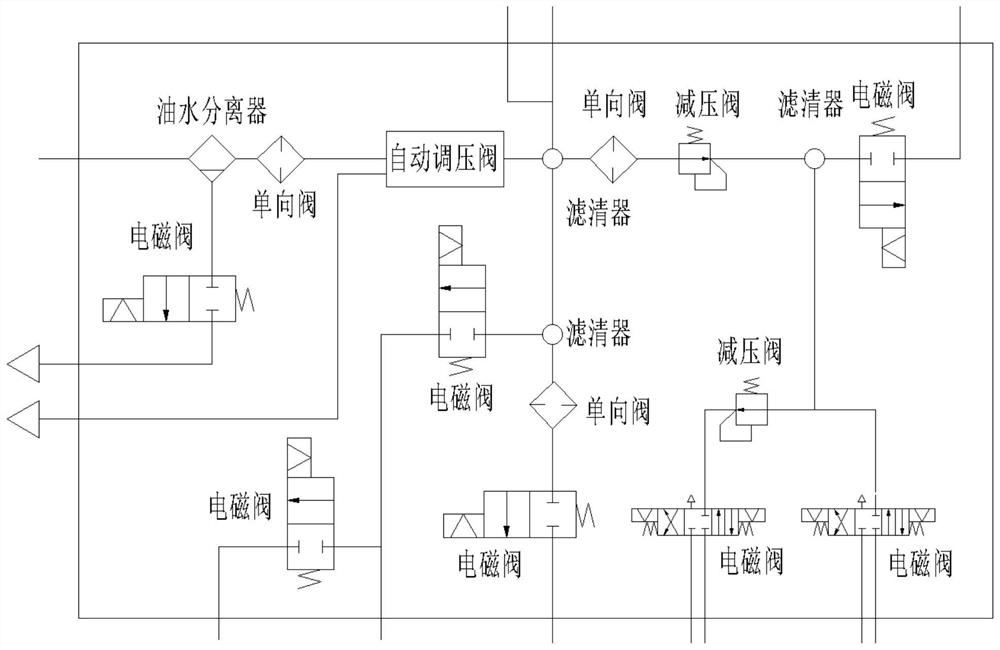

[0029] like figure 1 and figure 2 As shown, the present invention is a combined valve group for compressed air treatment for armored vehicles, including a gas treatment system located between the air source device and the actuator, and the gas treatment system includes an oil-water separator 1 and a plurality of control elements, It also includes a valve seat 7, on which an air source interface, a load interface and an air flow channel located inside it are provided, and the oil-water separator 1 and the control element are installed on the valve seat 7 and have respective internal air passages. They are all communicated with the air flow channel. The air source device sends the gas into the air flow channel inside the valve seat 7 through the air source interface, and then passes through the gas processing system from the load interface to the actuator.

[0030] The air source device is the generation device of compressed air, and auxiliary devices for compressed air storag...

Embodiment 2

[0034] This embodiment describes the installation structure of the oil-water separator 1 .

[0035] like figure 2 As shown, in the present invention, the oil-water separator 1 is fixed on one side of the valve seat 7 through a connecting assembly, the connecting assembly includes a bottom plate 8, a mounting plate 9 and a screw 10, one side of the bottom plate 8 is connected to the valve seat The side wall of 7 is connected, the mounting plate 9 is fixed on the bottom of the oil-water separator 1, and a plurality of light holes are arranged around it, the number of the screws 10 is consistent with the number of light holes, and the ends of the rods respectively pass through them. After a light hole, it is screwed to the bottom plate 8.

Embodiment 3

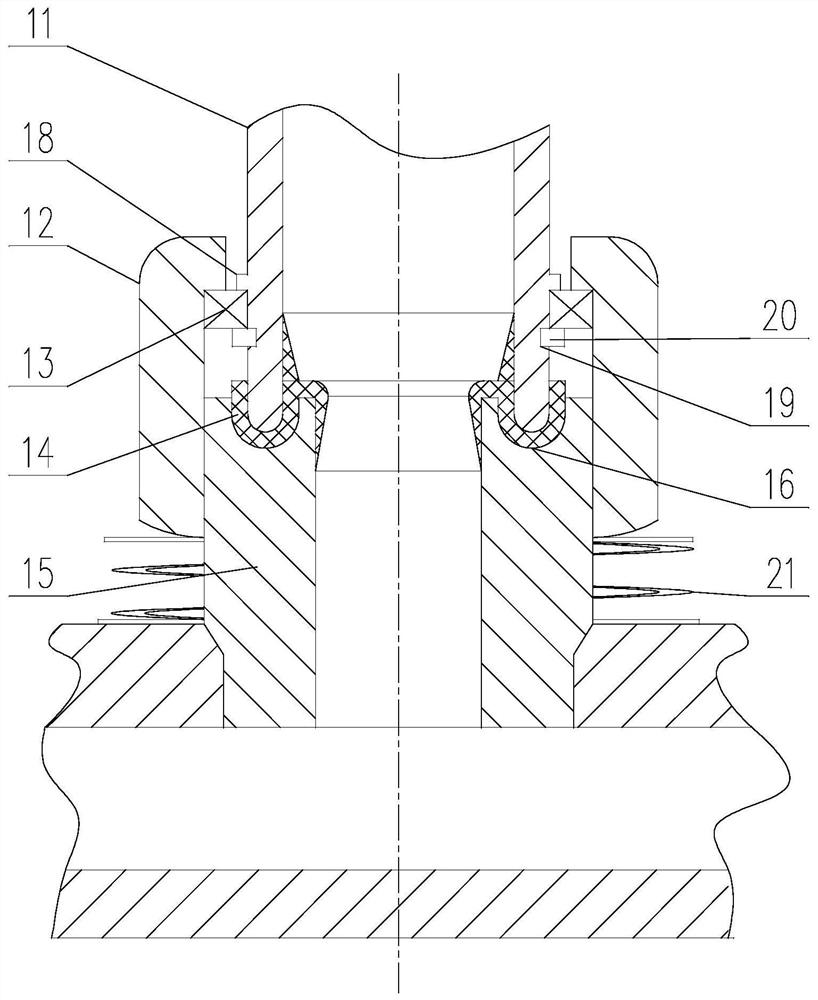

[0037]In this embodiment, on the basis of the above-mentioned embodiment, the sealing connection between the gas outlet port of the oil-water separator and the valve seat 7 is described.

[0038] like image 3 As shown, in the present invention, the air outlet end of the air outlet pipe 11 of the oil-water separator 1 is sealedly connected to the air inlet end communicated with the air flow channel through a connecting assembly, and the connecting assembly includes a nut 12 whose axes coincide with each other, a bearing 13. The sealing ring 14 and the external thread cylinder 15, the bearing 13 is sleeved on the air outlet pipe 11 and is axially fixed on the air outlet pipe 11, the nut 12 is sleeved on the bearing 13, and is connected to the outer part of the bearing 13. Ring interference fit, the bottom of the external thread cylinder 15 is inserted into the valve seat 7, and is sealed and welded with the valve seat 7, and its top is inserted into the inner hole of the nut 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com