Endoscopic heat pipe visualization device and test method

An endoscopic heat pipe technology, applied in the "endoscopic" heat pipe visualization device and testing field, can solve the problem of visualization of the working fluid two-phase flow mechanism inside the metal wall heat pipe, which has not been reported and cannot truly reflect the phase change of the working fluid Behavior and mechanisms of two-phase heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

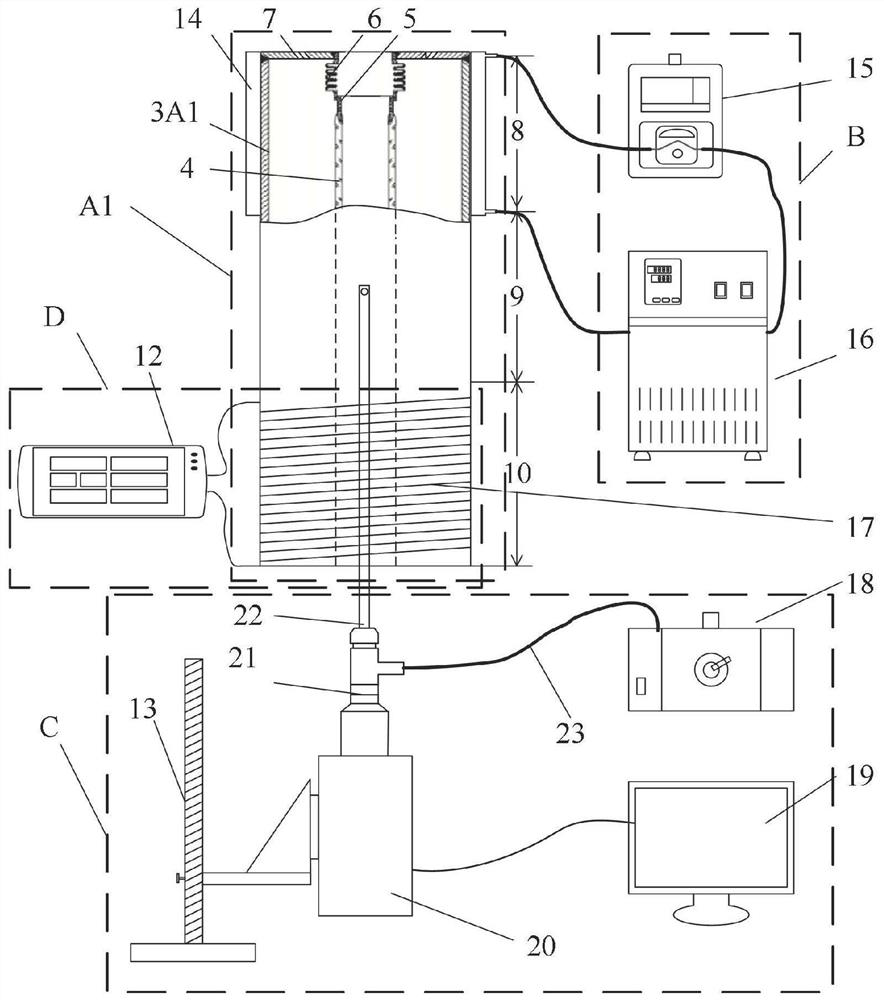

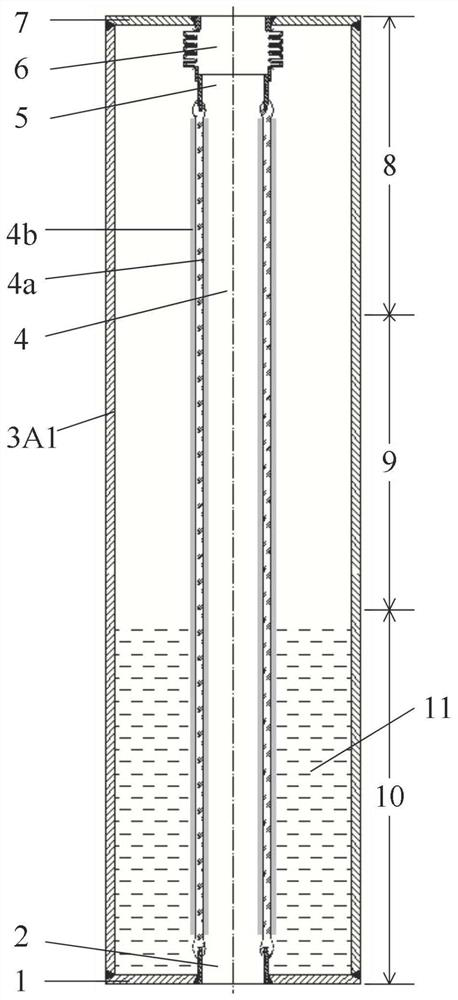

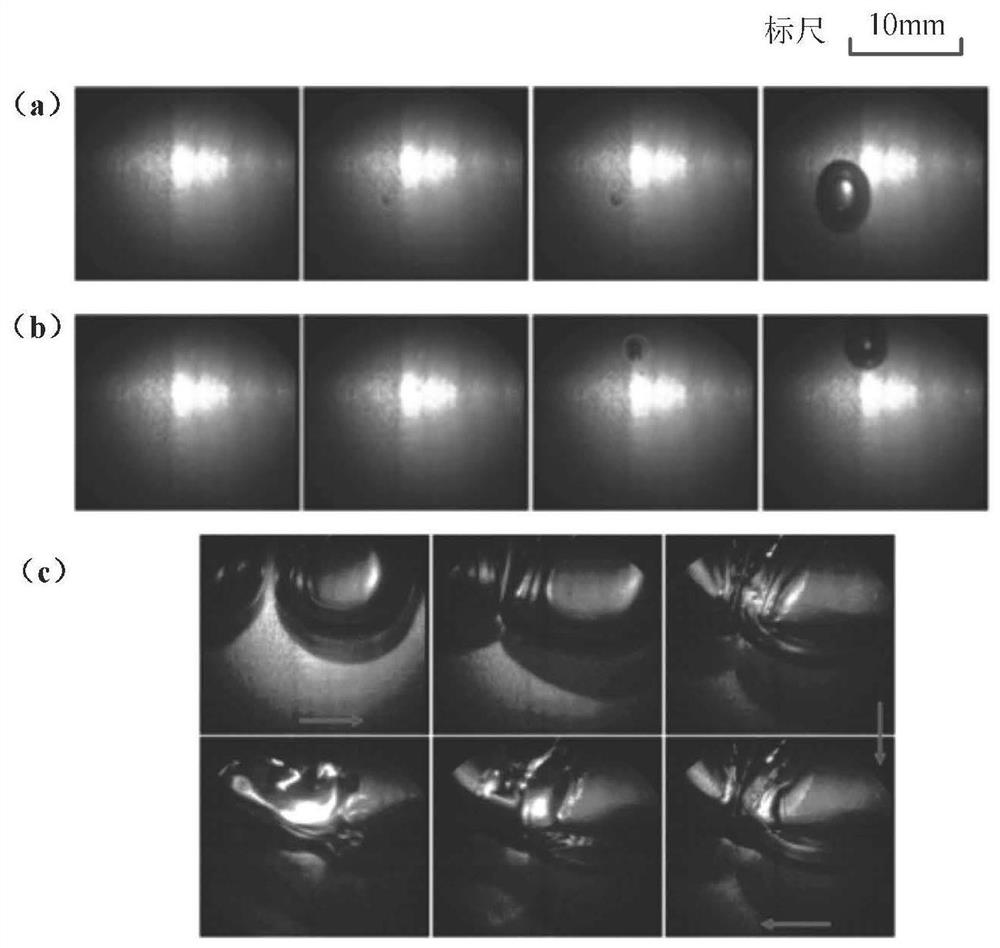

[0030] figure 1 Shown is the test system diagram of the "endoscopic" gravity heat pipe visualization device of this example, and the structural schematic diagram of the "endoscopic" gravity heat pipe of this example is shown in figure 2 shown.

[0031] The "endoscopic" gravity heat pipe visualization experiment device consists of an "endoscopic" gravity heat pipe A1, a cooling system B, a shooting system C and a heating system D; the "endoscopic" gravity heat pipe A1 consists of a gravity heat pipe main pipe 3A1 , a transparent glass tube 4, a first Kovar ring 2, a second Kovar ring 5, an expansion joint 6, a first end cap 1 and a second end cap 7, and a working fluid 11; wherein the heat pipe main body tube 3A1 is composed of The evaporation section 10, the heat insulation section 9 and the condensation section 8 are composed; the main tube 3A1 of the gravity heat pipe is placed vertically, the transparent glass tube 4 is coaxially placed inside the main tube 3A1 of the gra...

Embodiment 2

[0036] Figure 4 Shown is the structural schematic diagram of the "endoscopic" gravity heat pipe of this example. The structural form, some materials and the testing process of this embodiment are basically the same as those of Embodiment 1. The difference is: the main tube 3A1 of the "endoscopic" gravity heat pipe is a combined tube, the material is aluminum, and the characteristic shape of the condensation section 8 is a bellows, the total length is 450m, the diameter of the straight section of the bellows is 80mm, and the peak diameter of the bellows is 100mm. The length of the straight section is 20mm, the length of the arc section is 30mm, and the thickness is 3mm; the characteristic shape of the heat insulation section 9 is a straight pipe, the length is 100mm, the diameter is 80mm, and the thickness is 3mm; the characteristic shape of the evaporation section 10 is a straight pipe, the length is 400mm, the diameter is 80mm, and the wall The thickness is 3mm, the inner w...

Embodiment 3

[0039] Figure 5 Shown is the test system diagram of the "endoscopic" loop heat pipe visualization device of this example, and the structural schematic diagram of the "endoscopic" loop heat pipe of this example is shown in Image 6 As shown; the visualization device of this example is basically the same as that of Example 1, the difference is that the "endoscopic" loop heat pipe A2 consists of a loop heat pipe main body tube 3A2, a transparent glass tube 4, a first Kovar ring 2 and Second Kovar ring 5, expansion joint 6, first end cap 1 and second end cap 7, U-shaped liquid storage pipe 9c, steam ascending pipe 9b, condensate descending pipe 9a, condensation section 8, liquid-absorbing core 10a and the heat pipe working fluid 11; the loop heat pipe main tube 3A2 is placed horizontally, the transparent glass tube 4 is placed inside the loop heat pipe main tube 3A2, and the two ends are respectively connected with the first Kovar alloy ring 2 and the second Kovar alloy ring 5 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com