Nanoscale PN junction diode rectifier based on MnBi2Te4 single layer

A PN junction diode and diode rectifier technology is applied in the field of nano-scale electronic devices, which can solve the problems of few reports on the design of nano-devices, and achieve the effects of excellent rectification performance, adjustable size and ultra-thin structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

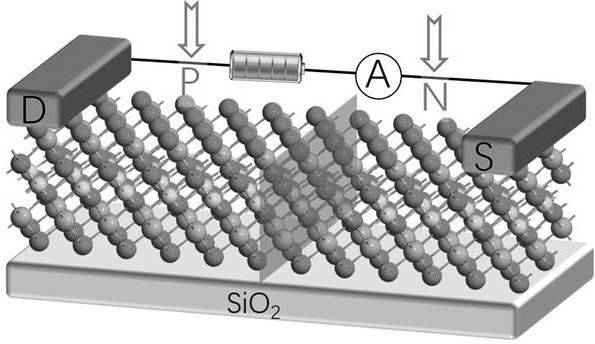

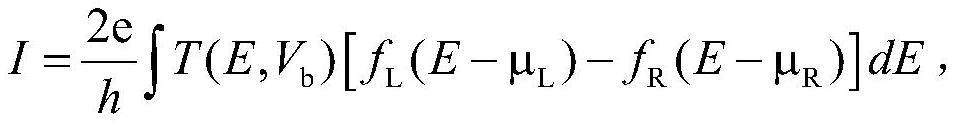

[0015] The invention is constructed by MnBi 2 Te 4 A PN junction diode device obtained by P-type doping and N-type doping at both ends of a single-layer structure of the material. The present invention uses the industry's advanced device design tool QuantumATK ( Smidstrup,et al.,QuantumATK:an integrated platform of electronic and atomic-scalemodelling tools[J].J.Phys.:Condens.Matter 32,015901(2020)) for device model design and performance measurement.

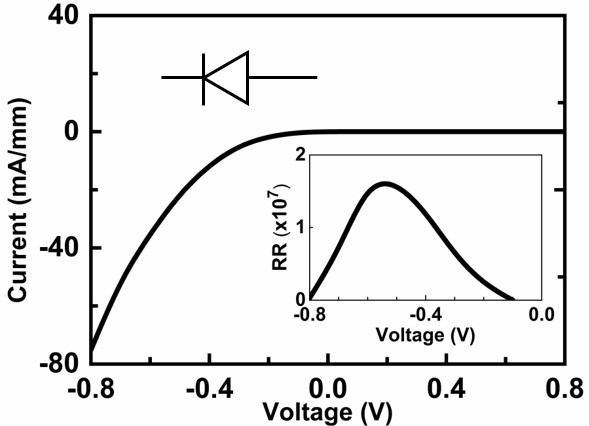

[0016] Through the measurement of its electrical properties such as current-voltage curve, it is revealed that the MnBi-based 2 Te 4 The rectification function of the single-layer nanoscale PN junction diode rectifier provides a relevant theoretical basis and model construction scheme for the further design and realization of rectifier diode nanodevices with ultra-thin structure, low power consumption, excellent performance and adjustable size.

[0017] This is based on MnBi 2 Te 4 The realization of the rectification effect of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com