Silver brazing material and joining method using said silver brazing material

A joining method and technology of silver brazing filler metal, applied in the direction of welding equipment, welding medium, welding equipment, etc., can solve the problems of quality reduction of the joint

Pending Publication Date: 2020-11-27

TANAKA PRECIOUS METAL IND +1

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Carbon steel has a phase transition point (A1 point) around 730°C. Therefore, if joining is performed at a temperature exceeding this temperature, the phase transition of the materials to be joined may occur, and the joint may be caused by a change in material properties. lower quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

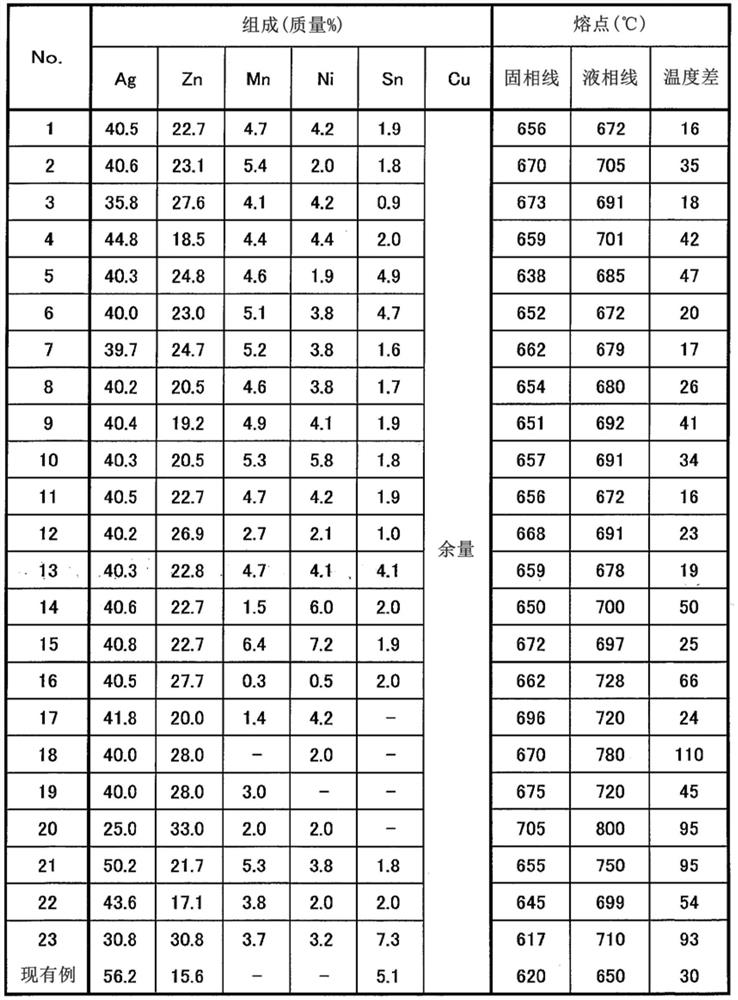

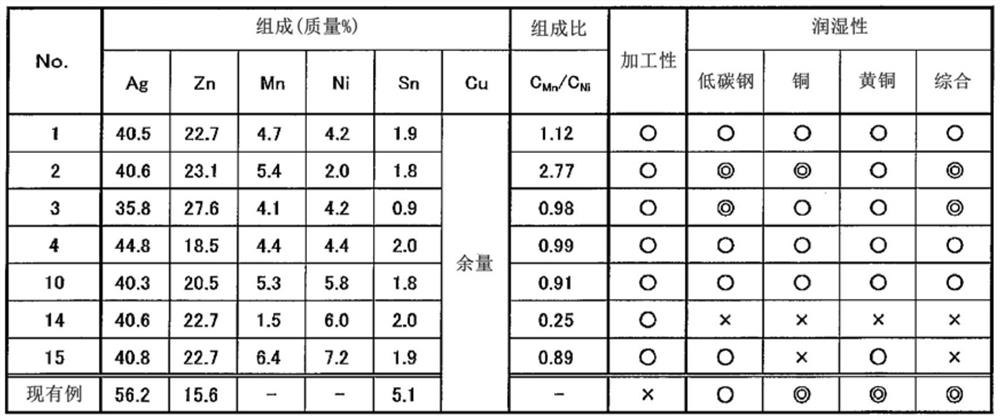

[0057] Embodiments of the present invention will be described below. In this embodiment, silver solders (Ag—Cu-based alloys) of various compositions are produced by melting and casting, and their solidus temperature and liquidus temperature are measured. Then, the workability and wettability of each solder were evaluated.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a silver brazing material in which the essential constituent elements are silver, copper, zinc, manganese, nickel, and tin. The silver brazing material comprises 35 to45 mass% of silver, 18 to 28 mass% of zinc, 2 to 6 mass% of manganese, 1.5 to 6 mass% of nickel, and 0.5 to 5 mass% of tin, with the balance being copper and unavoidable impurities. In addition, by establishing a prescribed relationship between the manganese content (CMn) and nickel content (CNi) within the indicated composition range, the silver brazing material can also have good properties with regard to processability and wettability. The silver brazing material according to the present invention provides a reduction in the melting point and a reduction in the temperature difference between the solidus temperature and liquidus temperature, while lowering the silver content.

Description

technical field [0001] The present invention relates to silver solder. Specifically, it relates to a silver solder having a low melting point while reducing the silver content and having a small temperature difference between a solidus line and a liquidus line, and a joining method using the same. Background technique [0002] Silver solder has conventionally been used for joining copper alloys such as copper and brass, joining tool materials, or joining dissimilar metal materials. The silver solder has a silver-copper-based alloy (Ag-Cu-based alloy) as a basic component, and additive elements such as zinc and tin are added thereto, and silver solders with various compositions are known. [0003] In addition, as requirements for silver brazing filler metals, reduction in silver content (less silver) and lower melting point (lower melting point) can be cited. Since silver is a precious metal, it is required to reduce the cost of the raw material metal by reducing the amount...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/30B23K1/00B23K1/19C22C5/06C22C5/08C22C30/06

CPCB23K1/19B23K35/30C22C5/06C22C5/08C22C30/06B23K35/3006C22C30/02C22C30/04B23K1/0008B23K1/008B23K31/025B23K2101/20B23K2103/04B23K2103/12C22C5/00C22C30/00B23K35/302

Inventor 岸本贵臣高桥昌宏照井贵志松康太郎

Owner TANAKA PRECIOUS METAL IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com