A gold catalyst modified with sulfur-containing silane coupling agent for acetylene hydrochlorination

A technology of sulfur-silane coupling agent and catalyst, which is applied in the field of sulfur-containing silane coupling agent-modified gold catalyst and its preparation, can solve the problems that the stability of gold-based catalyst hinders industrial application, catalyst deactivation, etc., and achieves a simple and efficient preparation process. Convenience and safety, solve environmental problems, increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

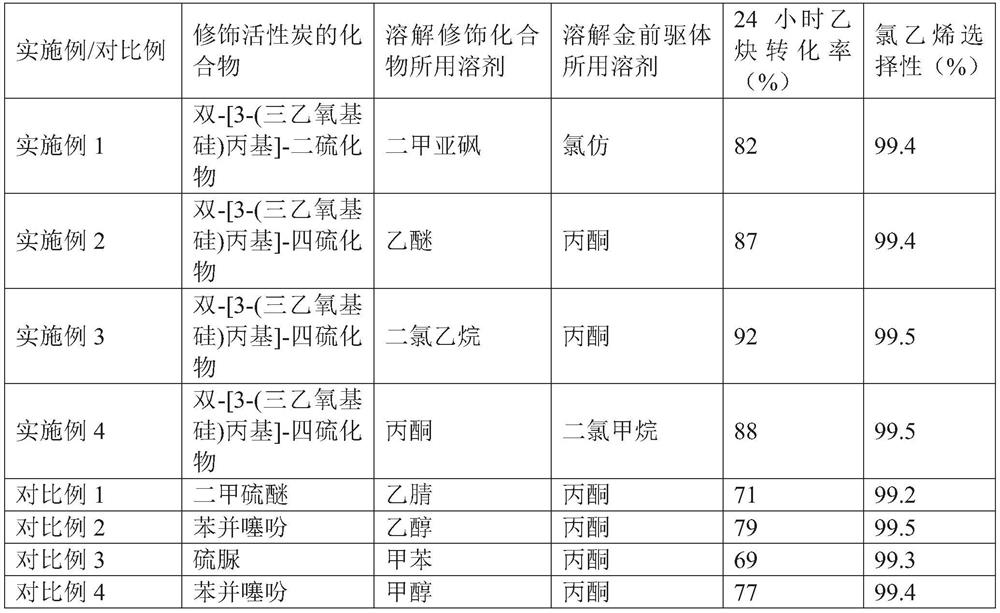

Embodiment 1

[0038] Embodiment 1 catalyst preparation

[0039] Weigh 3.3g of bis-[3-(triethoxysilyl)propyl]-disulfide and dissolve it in 35ml of dimethyl sulfoxide, add a certain amount of sodium hydroxide solution (1mol / L) to adjust the pH of the solution to 13, the above solution was added dropwise into a beaker containing 50 g of activated carbon, and stirred at a temperature of 100°C for 15 hours, and the stirred activated carbon obtained was washed with a large amount of water until it was neutral, and then centrifuged and filtered , drying and other steps to obtain activated carbon modified with sulfur-containing silane coupling agent; weigh 1.35g of chloroauric acid and dissolve it in 200ml of chloroform to obtain an impregnation solution containing chloroauric acid; take 48.65g of the prepared sulfur-containing silane coupling agent The activated carbon modified by the agent is soaked in the impregnating solution containing chloroauric acid; the soaked activated carbon is centrifug...

Embodiment 2

[0040] Embodiment 2 catalyst preparation

[0041]Weigh 2.9g of bis-[3-(triethoxysilyl)propyl]-tetrasulfide and dissolve it in 35ml of ether, add a certain amount of sodium hydroxide solution (1mol / L) to adjust the pH of the solution to 11~ 13. Add the above solution dropwise into a beaker containing 50g of activated carbon, and stir for 17 hours at a temperature of 35°C. The stirred activated carbon obtained is washed with a large amount of water until it is neutral, and then centrifuged, filtered, Steps such as drying obtain the activated carbon modified by the sulfur-containing silane coupling agent; weigh 0.75g of chloroauric acid and dissolve it in 200ml of acetone to obtain an impregnating solution containing chloroauric acid; take 49.25g of the prepared sulfur-containing silane coupling agent The modified activated carbon is soaked in the impregnating solution containing chloroauric acid; the soaked activated carbon is centrifuged, filtered and then dried to finally obta...

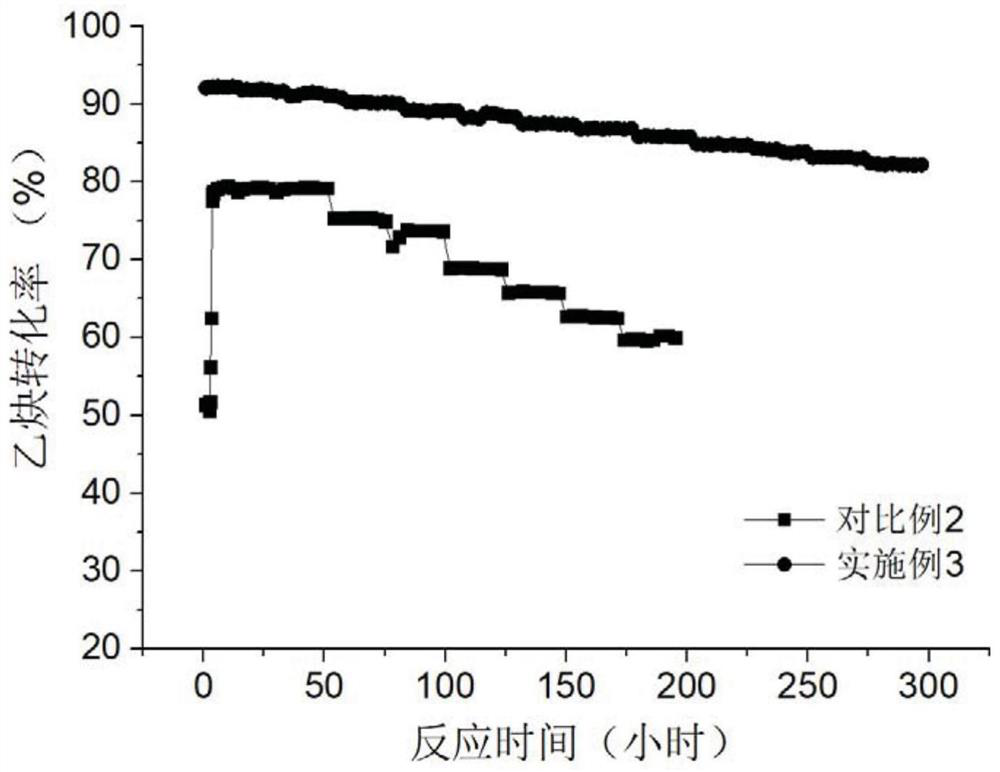

Embodiment 3

[0042] Embodiment 3 catalyst preparation

[0043] Weigh 2.9g of bis-[3-(triethoxysilyl)propyl]-tetrasulfide and dissolve it in 35ml of dichloroethane, add a certain amount of sodium hydroxide solution (1mol / L) to adjust the pH of the solution to 13, the above solution was added dropwise into a beaker containing 50 g of activated carbon, and stirred at a temperature of 80°C for 17 hours, and the stirred activated carbon obtained was washed with a large amount of water to neutrality, and then centrifuged and filtered , drying and other steps to obtain activated carbon modified with sulfur-containing silane coupling agent; weigh 0.75g of chloroauric acid and dissolve it in 200ml of acetone to obtain an impregnating solution containing chloroauric acid; take 49.25g of the prepared sulfur-containing silane coupling agent The activated carbon modified by the agent is soaked in the impregnating solution containing chloroauric acid; the soaked activated carbon is centrifuged, filtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com