Fluorine-oxygen microcrystalline glass based on rare earth ion in-situ crystallization as well as preparation method and application of fluorine-oxygen microcrystalline glass

A rare earth ion, glass-ceramic technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of optical scattering, high crystallinity, small luminous enhancement, etc., to achieve strong adaptability and applicability , Simple process, controllable effect of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

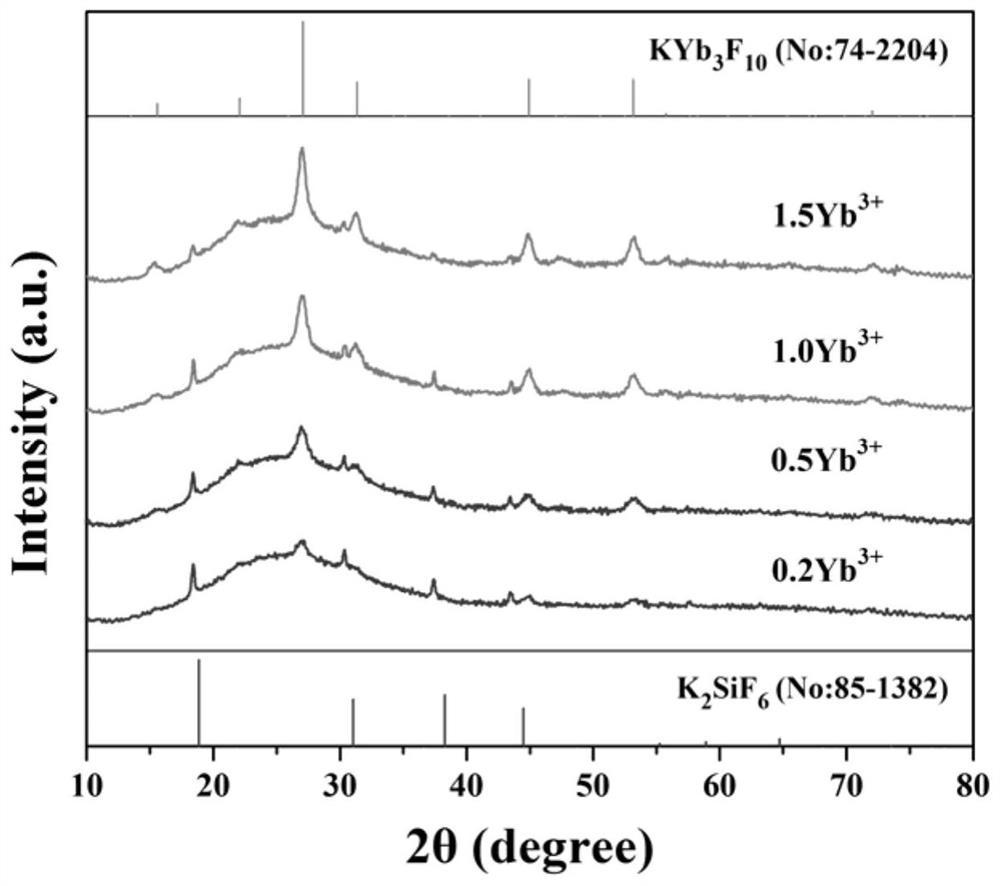

[0030] (1) Glass-ceramics adopts the following formula: including matrix glass components and YbF 3 , where YbF 3 Incorporated in the form of external doping, the molar percentage is 1.0% of the matrix glass component;

[0031] The molar percentages of each component of the matrix glass component are:

[0032] GeO 2 :70%

[0033] MnF 2 :15%

[0034] NaF: 15%

[0035] (2) Weigh 50 g of high-purity powdery raw materials according to the composition formula, and fully mix them uniformly in a ball mill jar.

[0036] (3) Pour the uniformly mixed material into a 100ml quartz crucible, add a lid, put it into a high-temperature electric furnace, slowly raise the temperature to 1350°C and keep it warm for 30min, then put it into a stirring rod, stir at a slow speed (10 rpm) for 30min, Keep warm for another 1 hour, cool down to 1250°C and discharge, and shape into block glass samples.

[0037] (4) Put the glass into a muffle furnace, raise the temperature to 520° C. for precise ...

Embodiment 2

[0041] (1) Glass-ceramics adopts the following formula: including matrix glass components, YbF 3 and TbF 3 , where YbF 3 and TbF 3 Incorporated in the form of external doping, the molar percentages are 1.0% and 0.5% of the matrix glass component;

[0042] The molar percentages of each component of the matrix glass component are:

[0043]B 2 o 3 :70%

[0044] MgF 2 :15%

[0045] CsF: 15%

[0046] (2) Weigh 50 g of high-purity powdery raw materials according to the composition formula, and fully mix them uniformly in a ball mill jar.

[0047] (3) Pour the uniformly mixed material into a 100ml quartz crucible, add a lid, put it into a high-temperature electric furnace, slowly raise the temperature to 950°C and keep it warm for 30min, then put it into a stirring rod, stir at a slow speed (10 rpm) for 30min, Then keep it warm for 1 hour, cool down to 900°C and discharge, and shape it into a rectangular glass sample.

[0048] (4) Put the glass into a muffle furnace, raise...

Embodiment 3

[0052] (1) Glass-ceramics adopts the following formula: including matrix glass components and TmF 3 , where TmF 3 Incorporated in the form of external doping, the molar percentage is 1.0% of the matrix glass component;

[0053] The molar percentages of each component of the matrix glass component are:

[0054] TeO 2 :60%

[0055] ZnF 2 :20%

[0056] NaF: 20%

[0057] (2) Weigh 50 g of high-purity powdery raw materials according to the composition formula, and fully mix them uniformly in a ball mill jar.

[0058] (3) Pour the uniformly mixed material into a 100ml corundum crucible, add a lid, put it into a high-temperature electric furnace, slowly raise the temperature to 750°C and keep it for 30 minutes, then put it into a stirring rod, and stir at a slow speed (10 rpm) for 30 minutes, Keep warm for another 1 hour, cool down to 700°C and discharge, and shape into a rectangular strip-shaped glass sample.

[0059] (4) Put the glass into a muffle furnace, raise the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com