Azobenzene derivative, preparation method thereof, azobenzene-based light-operated reversible adhesive and use method thereof

A technology of azobenzene derivatives and azophenyl, applied in the field of azobenzene derivatives and their preparation, azophenyl light-controlled reversible adhesives, can solve the problems of large local stress, poor products, wrinkles and the like , to achieve the effect of low cost, easy cleaning and recycling, and excellent adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

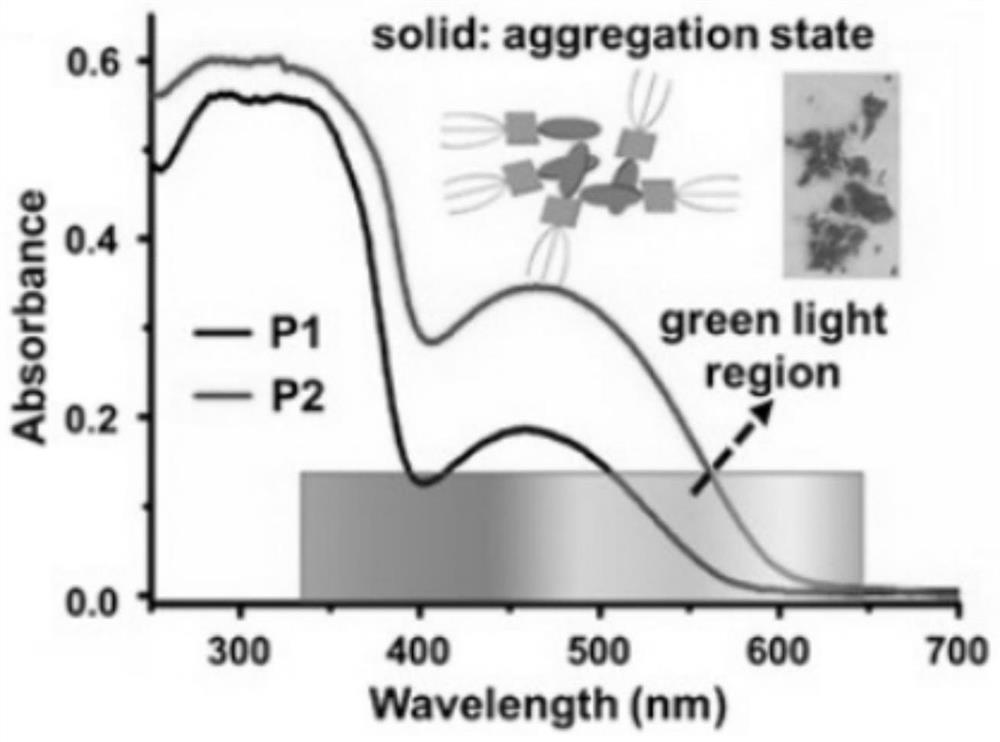

[0029] A kind of azobenzene derivative, denoted as P1, its molecular structure is as follows:

[0030]

[0031] The preparation method of P1 is: take azobenzene, 3,4,5-tripentyloxybenzoic acid and 2,2'-dihydroxy-1,1'-binaphthalene at a ratio of 1:1:1 Phenol, put the above three raw materials into a reaction kettle filled with water to participate in the reaction together, stir evenly, and continue the reaction for 30 minutes at 20°C, filter (suction filter) and dry the reacted mixture, and the obtained orange solid is P1 , and its melting point was measured to be 44°C.

[0032] The preparation method of the invention is simple and low in cost, and the reaction can take place at room temperature using water as a medium without a catalyst, and the conversion rate of raw materials is as high as 85%-93%.

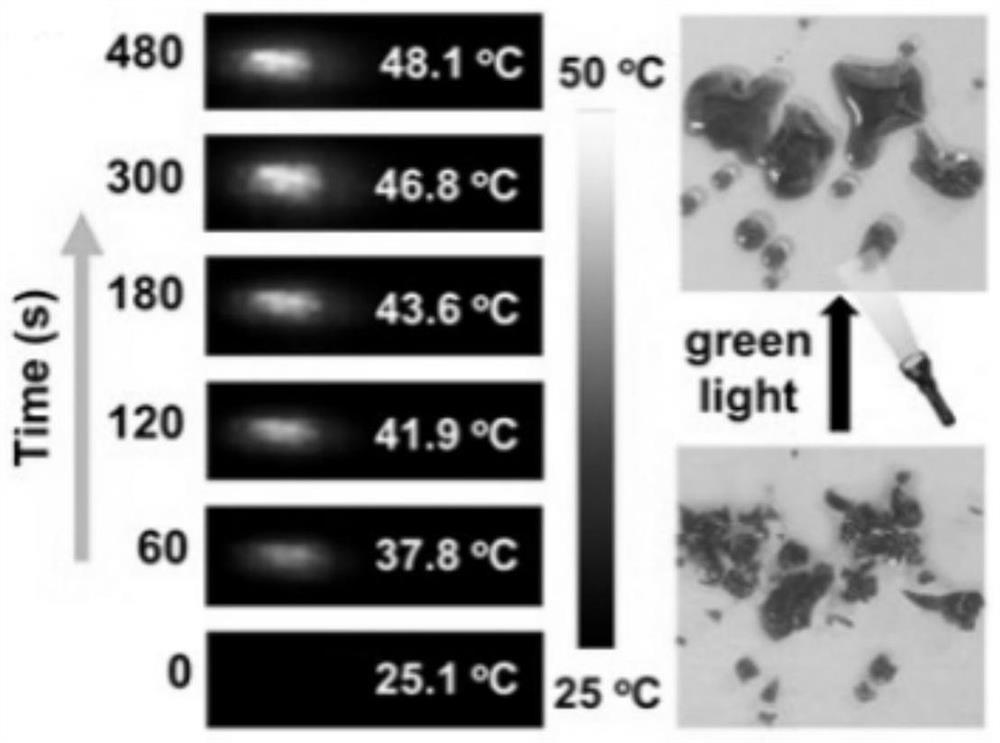

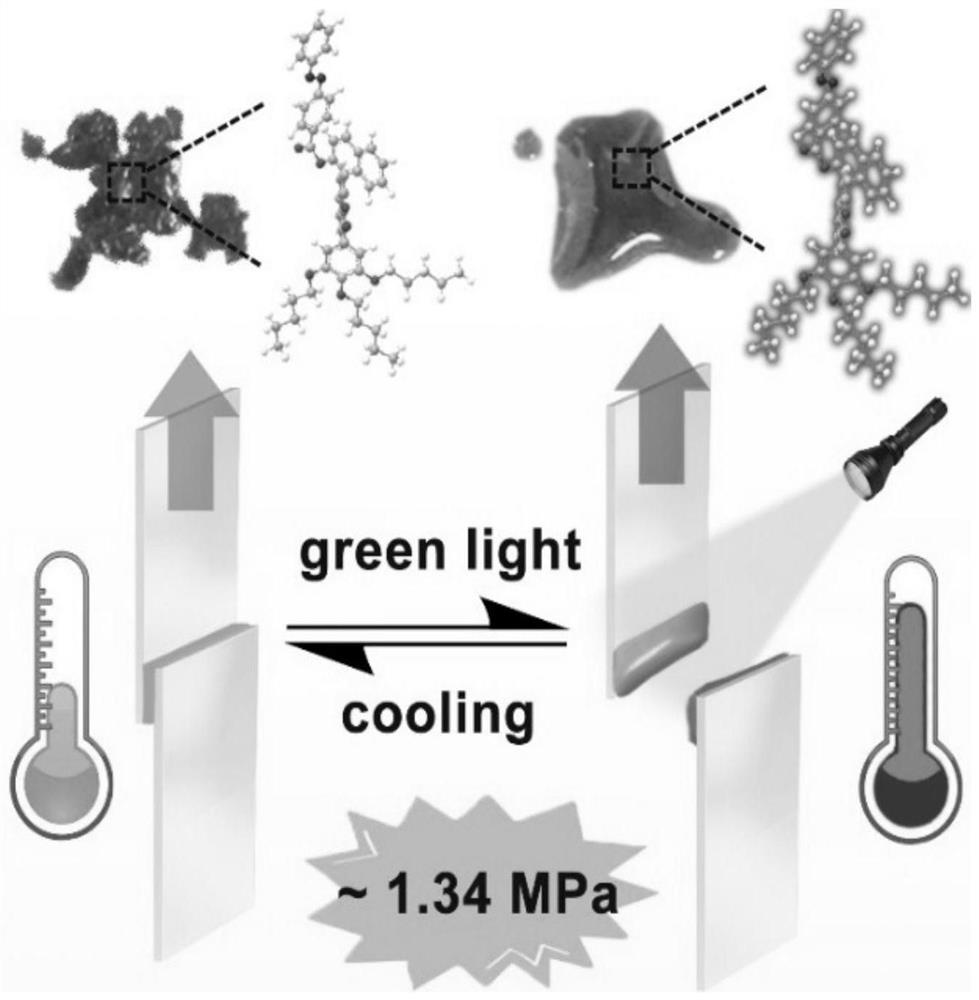

[0033] P1 is used as the adhesive of the optical switch (azophenyl light-controlled reversible adhesive) is very soluble in common organic solvents such as methylene chlorid...

Embodiment 2

[0035] The preparation method of P1 in this example is as follows: azobenzene, 3,4,5-tripentyloxybenzoic acid and 2,2'-dihydroxy-1,1 '-Binaphthol, put the above three raw materials into a reaction kettle filled with water to participate in the reaction together, stir evenly, and continue the reaction at 25°C for 20min, and the reacted mixture is filtered (suction filtered) and dried to obtain an orange The solid is P1.

Embodiment 3

[0037] The preparation method of P1 in this example is: take azobenzene, 3,4,5-tripentyloxybenzoic acid and 2,2'-dihydroxy-1,1 '-Binaphthol, put the above three raw materials into a reaction kettle filled with water to participate in the reaction together, stir evenly, and continue the reaction at 30°C for 25min, and the reacted mixture is filtered (suction filtered) and dried, and the obtained orange The solid is P1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com