Method for synthesizing glycolide in one step

A technology of glycolide and glycolide, applied in chemical recovery, organic chemistry and other directions, can solve the problems of catalyst recovery and utilization with harsh glycolide synthesis conditions, and the unrecyclable use of catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

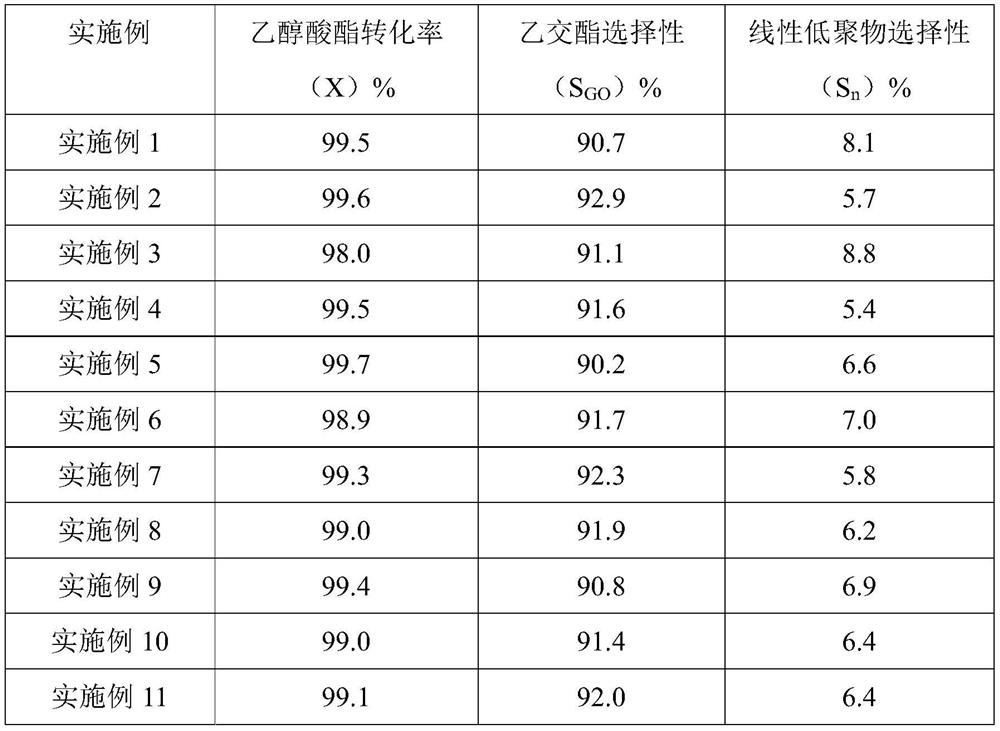

[0033] Sieve the tin-containing molecular sieve Sn-Beta (tin content: 1.7%, silicon-aluminum ratio: 3000) catalyst into 20-40 mesh particles, take 4g of catalyst and fill it into the middle section of the fixed-bed reaction tube, and fill the two ends of the reaction tube with inert quartz sand. The vaporization temperature of methyl glycolate was 220°C, the reaction temperature was 280°C, the feed rate of methyl glycolate was 8g / h, and the reaction was carried out under normal pressure. The reaction results are shown in Table 1.

Embodiment 2

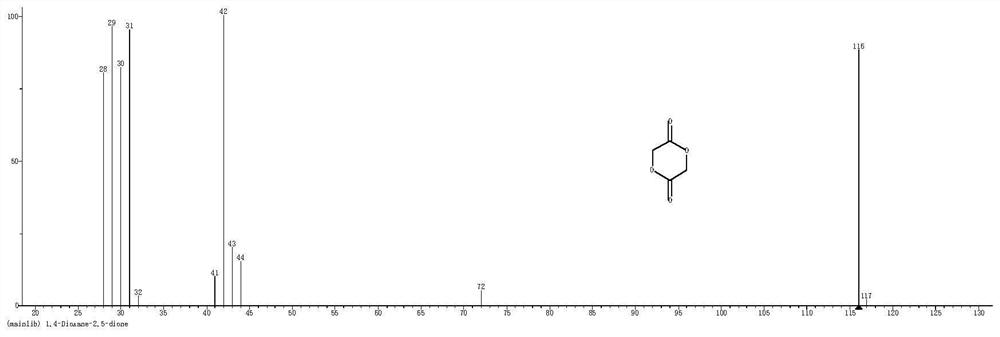

[0035] Sieve the tin-containing molecular sieve Sn-Beta (tin content: 1.7%, silicon-aluminum ratio: 3000) catalyst into 20-40 mesh particles, take 4g of catalyst and fill it into the middle section of the fixed-bed reaction tube, and fill the two ends of the reaction tube with inert quartz sand. The vaporization temperature of methyl glycolate was 260°C, the reaction temperature was 280°C, the feed rate of methyl glycolate was 8g / h, and the reaction was carried out under normal pressure. The reaction results are shown in Table 1. The material obtained by the reaction is separated and purified to obtain the product glycolide, and the mass spectrograms of the product are shown in the attached figure 1 .

Embodiment 3

[0037] Sieve the tin-containing molecular sieve Sn-Beta (tin content: 1.7%, silicon-aluminum ratio: 3000) catalyst into 20-40 mesh particles, take 4g of catalyst and fill it into the middle section of the fixed-bed reaction tube, and fill the two ends of the reaction tube with inert quartz sand. The vaporization temperature of methyl glycolate was 260°C, the reaction temperature was 250°C, the feed rate of methyl glycolate was 8g / h, and the reaction was carried out under normal pressure. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com