Genetically engineered bacterium with high yield of trans-aconitic acid as well as construction method and application of genetically engineered bacterium

A technology of trans-aconitic acid and genetic engineering strains, applied in the field of genetic engineering, can solve the problems of no large-scale production, many by-products, complex processes, etc., and achieve strong operability, strong application value, and easy screening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. Construction of a genetically engineered strain with high yield of trans-aconitic acid

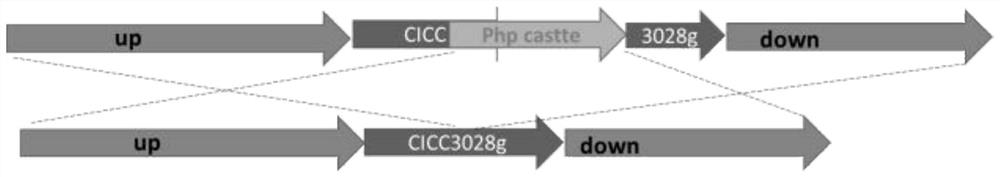

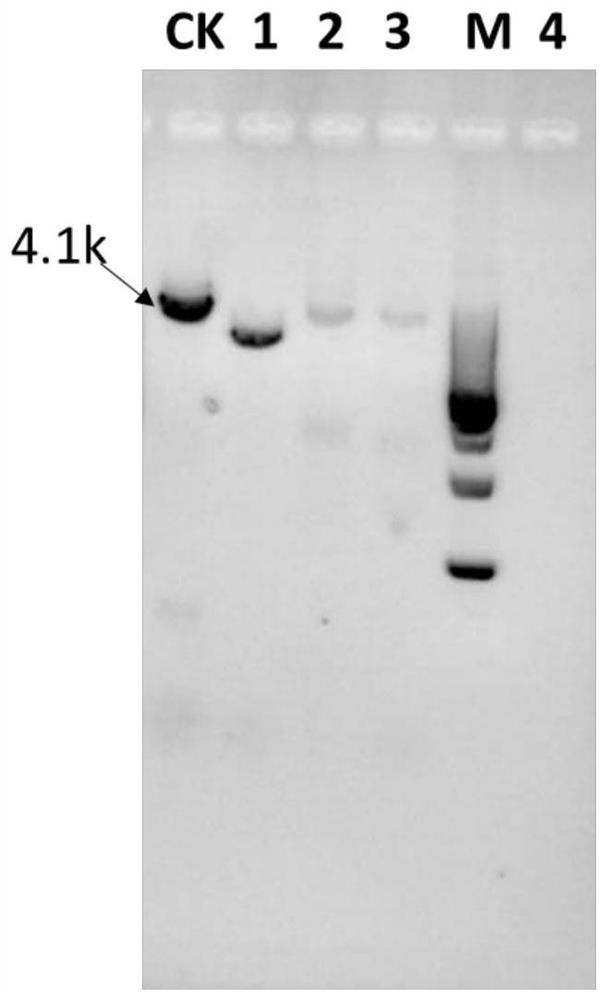

[0035] 1. Construction of targeting elements for knocking out CICC_3028g

[0036] according to figure 1 The targeting element strategy diagram of CICC_3028g, and the construction method of the recombinant Aspergillus terreus described in the present invention are described.

[0037] Amplification of the upstream and downstream homology arms of the cytochrome P450 monooxygenase gene: U-3028g-F (5'-CGACGGCCAGTGAATTCGAGctggtgggatgctgggtttagtct-3') and U-3028g-R (hph2) (5'-ctttacgcttgcgatcccgaagtcttcggaagacggcca-3') As a primer pair, the genome of Aspergillus terreus CICC40205 was used as a template for PCR amplification, and the upstream homology arm fragment of the CICC_3028g gene was obtained after the product was purified and recovered; D-3028g-R (5'-agatgtgcggcagatcagatccatcg-3') was used as a primer pair, and the genome of Aspergillus terreus CICC40205 was used as a t...

Embodiment 2

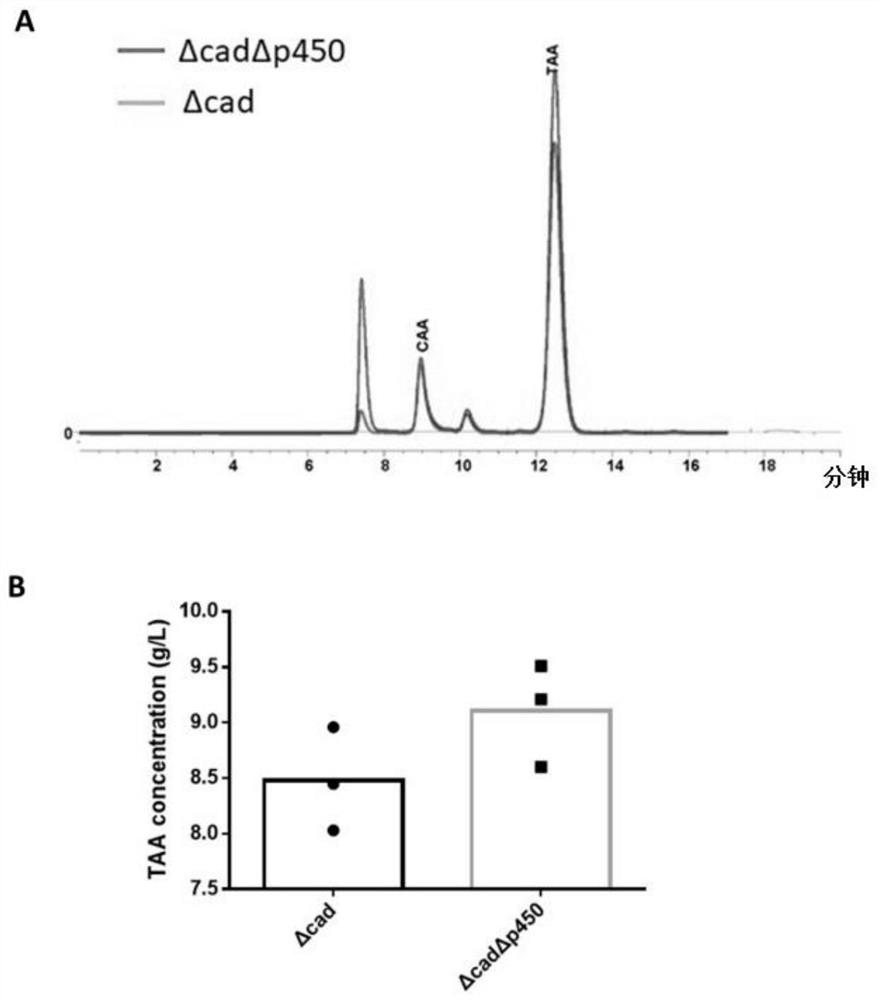

[0049] Example 2. Fermentation of recombinant Aspergillus terreus to produce trans-aconitic acid

[0050] 1. Shake flask screening of recombinant Aspergillus terreus strains producing trans-aconitic acid

[0051] The stably passaged recombinant Aspergillus terreus strains obtained in Example 2 were respectively inoculated into Aspergillus terreus sporulation medium, and cultured at 32° C. for 6 days to obtain mature spores. Then respectively inoculate the spores cultivated to maturity into the organic acid fermentation medium IPM (55ml IPM medium is housed in a 500ml Erlenmeyer flask), make two parallel bottles for each strain, and ferment for 72 hours in a shaker at 37°C with a rotation speed of 220rpm . The hyphae in the fermentation broth were removed by filtration, and the fermentation supernatant was properly diluted for HPLC analysis.

[0052] 2. Analysis of the content and purity of trans-aconitic acid in the fermentation broth

[0053] The fermentation supernatants ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com