Production process for improving desulfurization efficiency of EAF-LF molten steel in refining process

An EAF-LF, refining process technology is applied in the field of production technology for improving desulfurization efficiency in molten steel refining process, can solve problems such as being difficult to achieve, and achieve the effects of short time consumption, simple production process, and fast desulfurization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

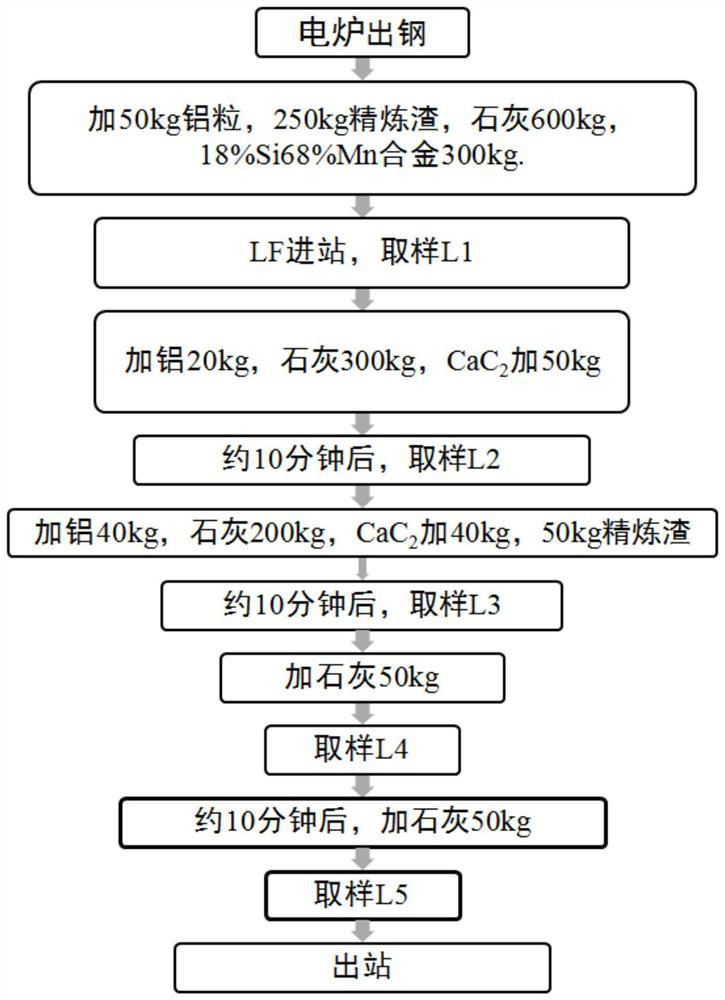

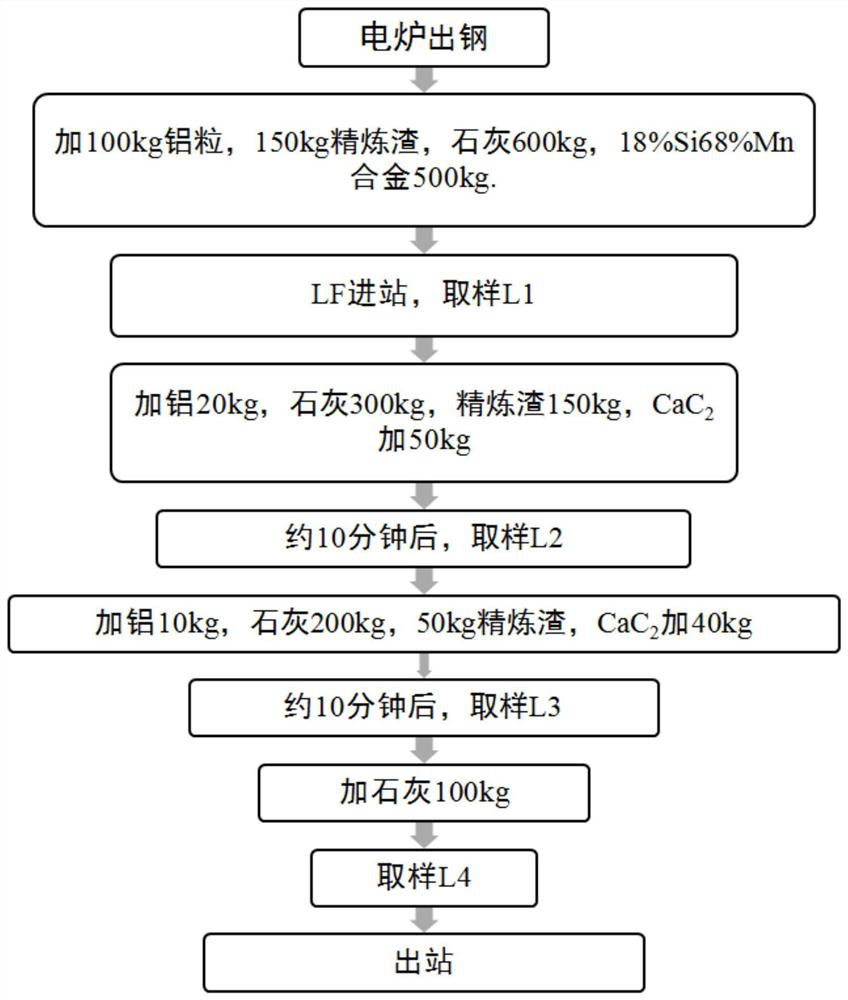

[0043] according to figure 2 The process operation; the details are as follows:

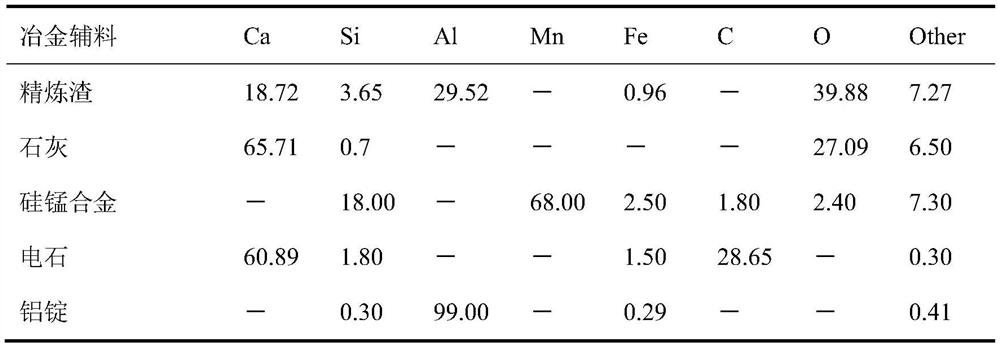

[0044] Adopt electric arc furnace to make steel, when the temperature reaches 1550-1600 degrees Celsius; tap 105 tons of steel, add 100Kg aluminum particles, 150Kg refining slag, 600Kg limestone to molten steel; Minutes later, enter the LF furnace, sample L1; then add 20Kg aluminum, 300Kg lime, 50Kg calcium carbide (calcium carbide), 150Kg refining slag and melt at 1550-1600 degrees Celsius for 10 minutes, sample L2, then add 10kg aluminum, 200Kg lime, Carbide 40kg, 50Kg refining slag, continue to smelt for 10 minutes, sample L3; then continue to add 100kg of lime, stir for 5 minutes, sample L4; after stirring, leave the station. The composition analysis of each sampling is shown in Table 2;

[0045] Table 2

[0046] C Si mn P Cu Ni Cr Mo v Nb Ti Al Ca S [O] E1 0.17 0.085 0.12 0.005 0.044 0.02 0.083 0.035 0 0.0004 0.0002 0.17 - 0.0262 185pp...

Embodiment 2

[0049] Others are consistent with embodiment 1, except that the composition of electric furnace tapping is slightly different; the composition of each sampling is shown in Table 3;

[0050] C Si mn P Cu Ni Cr Mo V Nb Ti Al Ca S [O] E1 0.16 0.085 0.12 0.005 0.040 0.04 0.085 0.034 0 0.0003 0.0002 0.16 - 0.0268 180ppm L1 0.26 0.28 0.39 0.0070 0.062 0.021 0.44 0.060 0.070 0.020 0.25 0.032 - 0.0146 L2 0.31 0.31 0.41 0.0075 0.055 0.020 0.45 0.080 0.080 0.020 0.26 0.033 - 0.0062 L3 0.33 0.32 0.43 0.0092 0.052 0.021 0.50 0.082 0.082 0.032 0.25 0.032 - 0.0029 L4 0.31 0.37 0.45 0.0088 0.058 0.022 0.515 0.081 0.072 0.031 0.26 0.040 - 0.002

[0051] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com