Pouring forming construction process for large sewage pool supporting arm ribbed beam type wall body

A construction process and technology for sewage pools, applied in the direction of walls, buildings, building components, etc., can solve the problems of unguaranteed quality, difficult adjustment, high reinforcement speed, etc. The effect of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Further detailed explanation through specific implementation mode below:

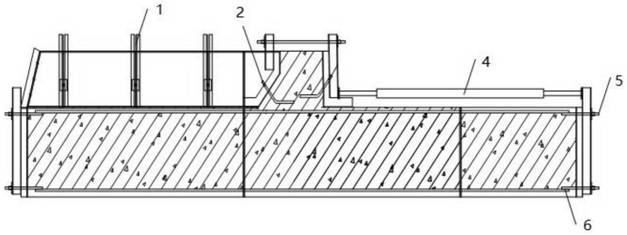

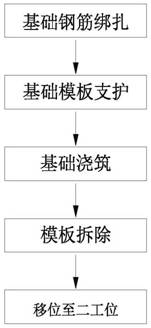

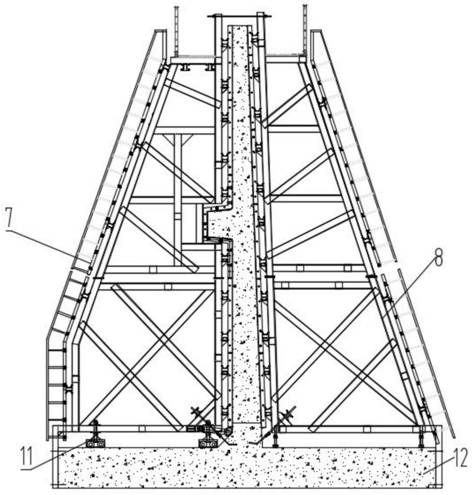

[0046] Such as Figures 1 to 7 As shown, a specific implementation method for the pouring and forming construction technology of the buttress rib beam type wall body of a large sewage pool is provided. The current reinforced concrete sewage pool is divided into two steps of construction. Reinforcement production, installation, formwork and pouring are carried out on the pool wall, resulting in the waste water pool taking too long in the entire pre-drilling construction period. At the same time, after the waste water pool is delivered for use, it often fails to meet the design strength requirements due to insufficient maintenance periods. In this embodiment, the collected potato starch wastewater is mainly pretreated and adjusted for storage. The designed sewage pool wall is 8.5m in height, 0.6m in bottom width, and 0.3m in top width. Rib beams of 0.5m*0.5m, in addition, there are triangular arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com