Five-axis numerical control machine tool

A technology for CNC machine tools and machine tools, applied in the field of machine tools, can solve the problems of reducing the protection and protection of the cutting fluid cooling, the inability to effectively control water and chips, and the difficulty of automatic cleaning of waste materials, etc. The effect of surface roughness, small shrinkage, and error reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

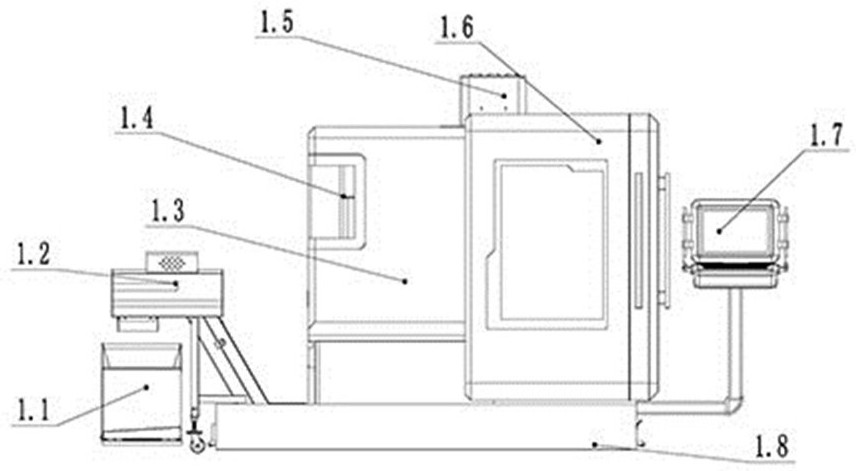

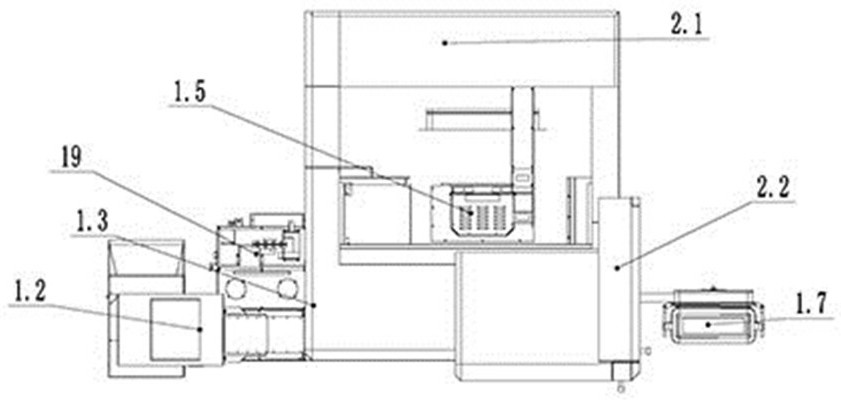

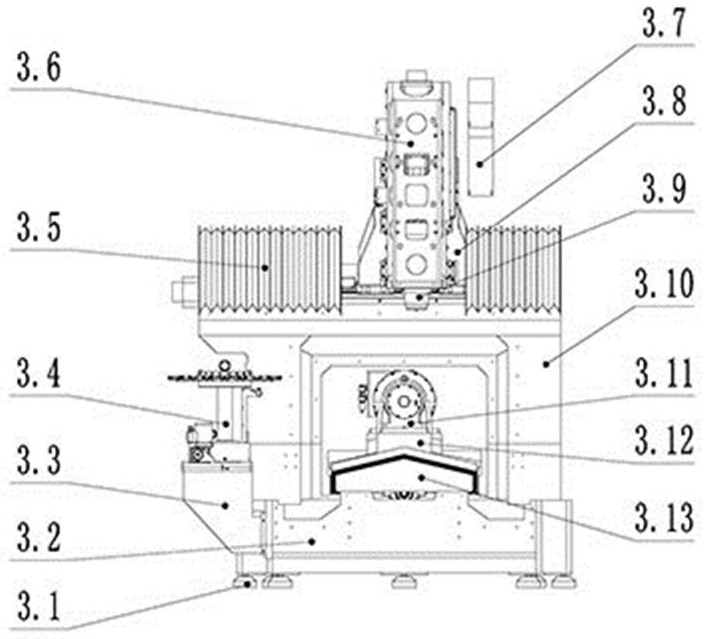

[0041] like Figure 1-39 As shown, a five-axis CNC machine tool includes chip collector 1.1, chip conveyor 1.2, left front shield 1.3, tool magazine perspective door 1.4, nose cover 1.5, moving door 1.6, system controller 1.7, water tank 1.8, oil and water Separator 1.9, rear guard 2.1, right moving door 2.2, horizontal foot 3.1, machine base 3.2, tool magazine bracket 3.3, tool magazine 3.4, telescopic protective cover 3.5, machine head casting 3.6, drag chain 3.7, ram 3.8, Main shaft 3.9, double support column 3.10, cradle 3.11, workbench 3.12, telescopic protective cover 3.13, guide rail 4.1, screw support seat 4.2, screw rod 4.3, servo motor 4.4 and machine head casting line rail 4.5;

[0042] The bottom of the CNC machine tool center is a workbench 3.12, which is fixed on the machine tool base 3.2 through the screw rod 4.3 of the machine base 3.2, the horizontal machine head casting line rail 4.5 and the clamping rail 5.1, and the workbench 3.12 is made of cast iron. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com