Corrugated box based on cold setting technology and using method

A corrugated box and corrugated packaging box technology, applied in the packaging, packaging, internal accessories and other directions of vulnerable items, can solve the problems of reducing the protective effect of corrugated boxes, beer bottle broken, beer bottle broken, etc., to improve friction, improve Efficiency, effect of increasing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

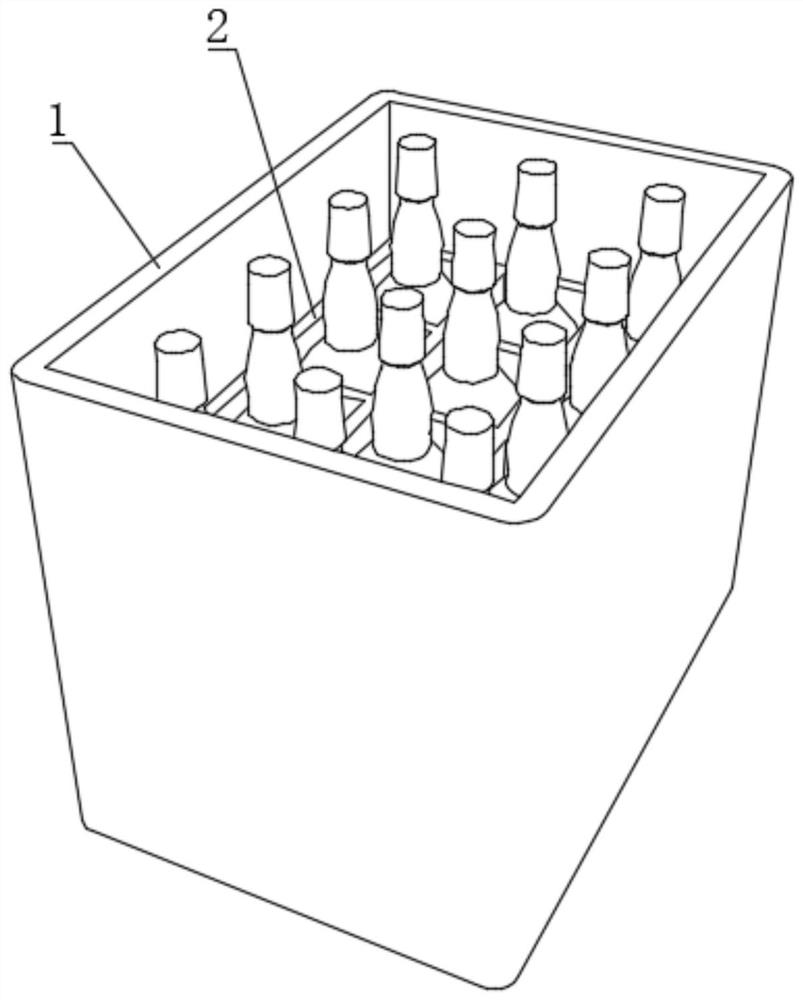

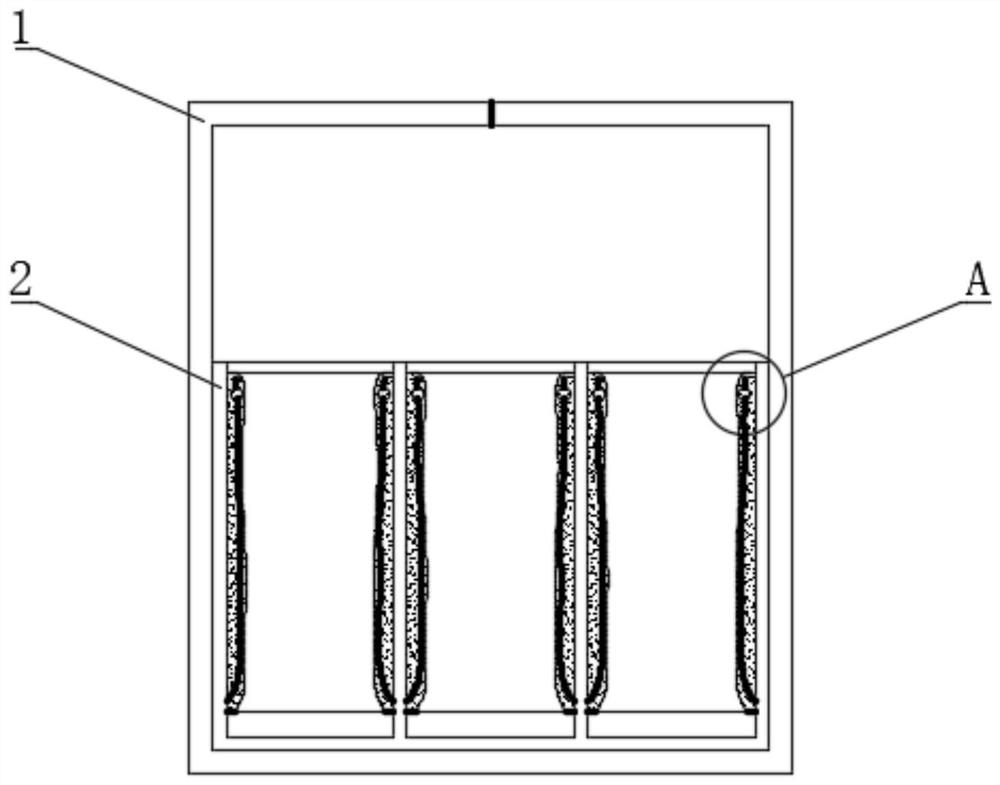

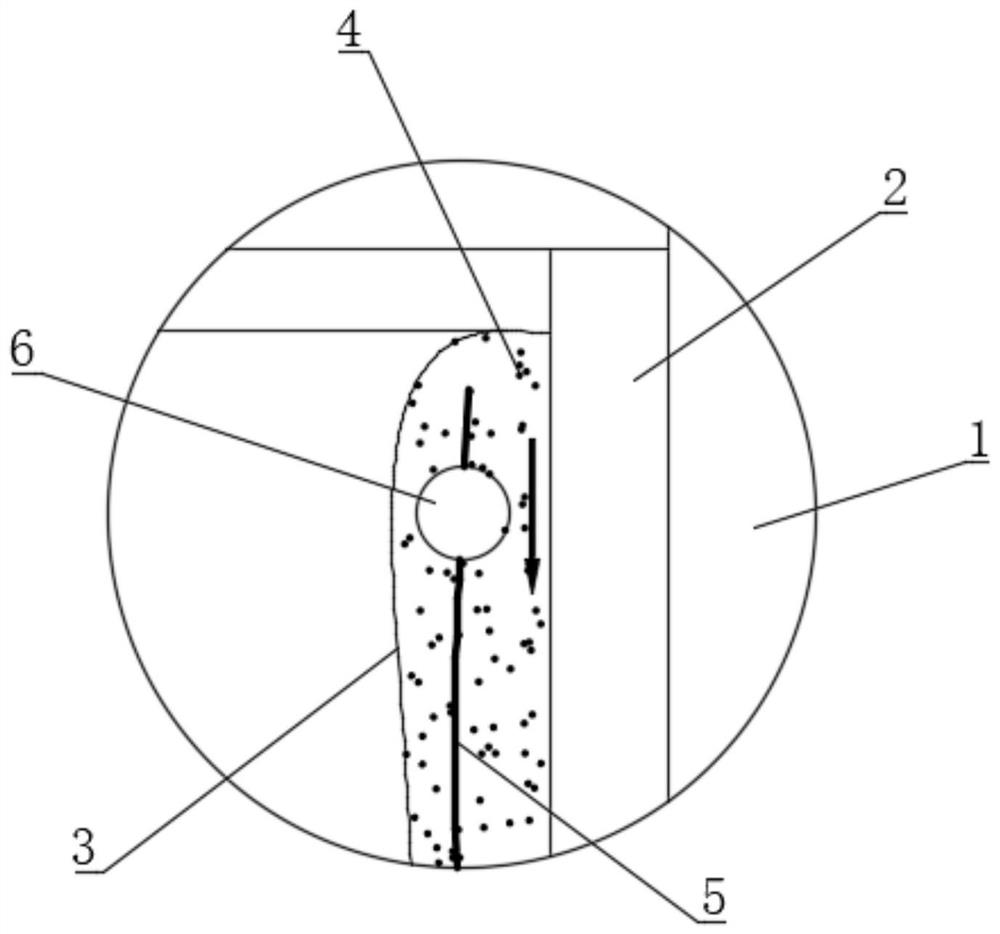

[0043] see Figure 1-5 , a corrugated box based on cold-setting technology, comprising an outer corrugated packaging box 1, the inner bottom of the outer corrugated packaging box 1 is fixedly connected with an inner corrugated partition seat 2, and the inner corrugated partition seat 2 includes a plurality of evenly distributed partition grooves, each The inner walls of each separation groove are fixedly connected with annular buffer cuffs 3 filled with refrigeration powder 4, and the inner walls of the annular buffer cuffs 3 close to the separation grooves are fixedly connected with deformation extrusion strips 5, and the deformation extrusion strips 5 The outer end is covered with a movable sliding ball 6, and the bottom end of the annular cushioning cuff 3 is dug with a plurality of uniformly distributed exchange holes 7, the inner wall of the exchange holes 7 is fixedly connected with a pre-dissolved layer 8, and the deformation extrusion strip 5 includes an annular The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com