Preparation method and application of hierarchical pore carbon material

A technology of carbon materials and multi-level pores, which is applied in chemical instruments and methods, carbon compounds, refined hydrocarbon oils, etc., can solve problems such as low opening degree, hindrance to applications, environmental and human hazards, and achieve low production costs and improved The effect of energy density and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

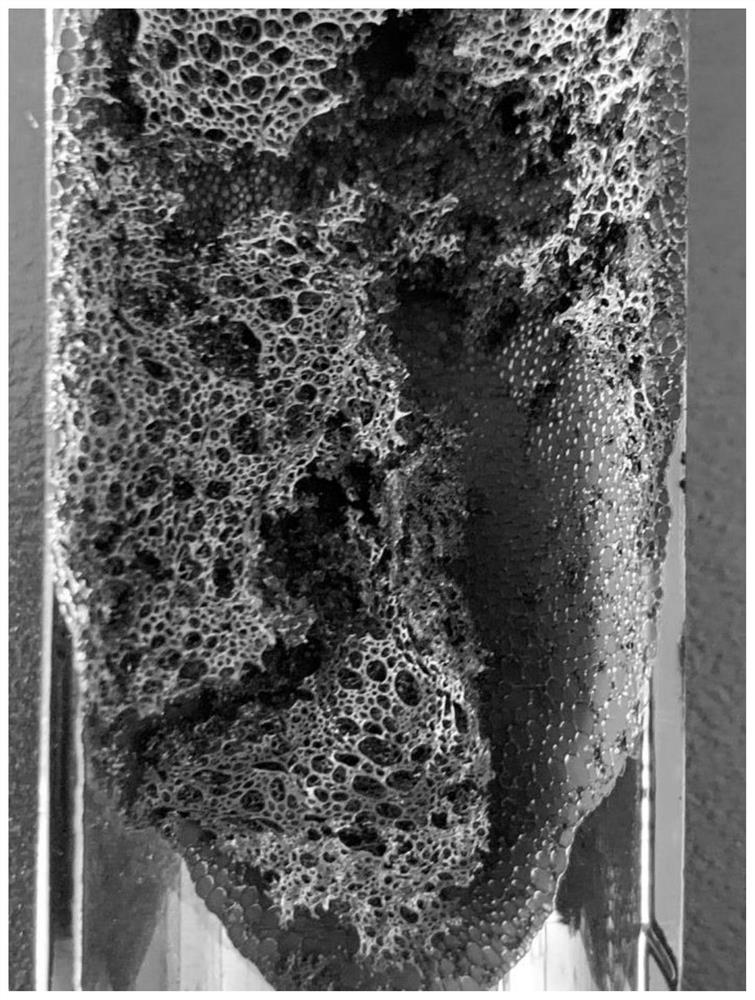

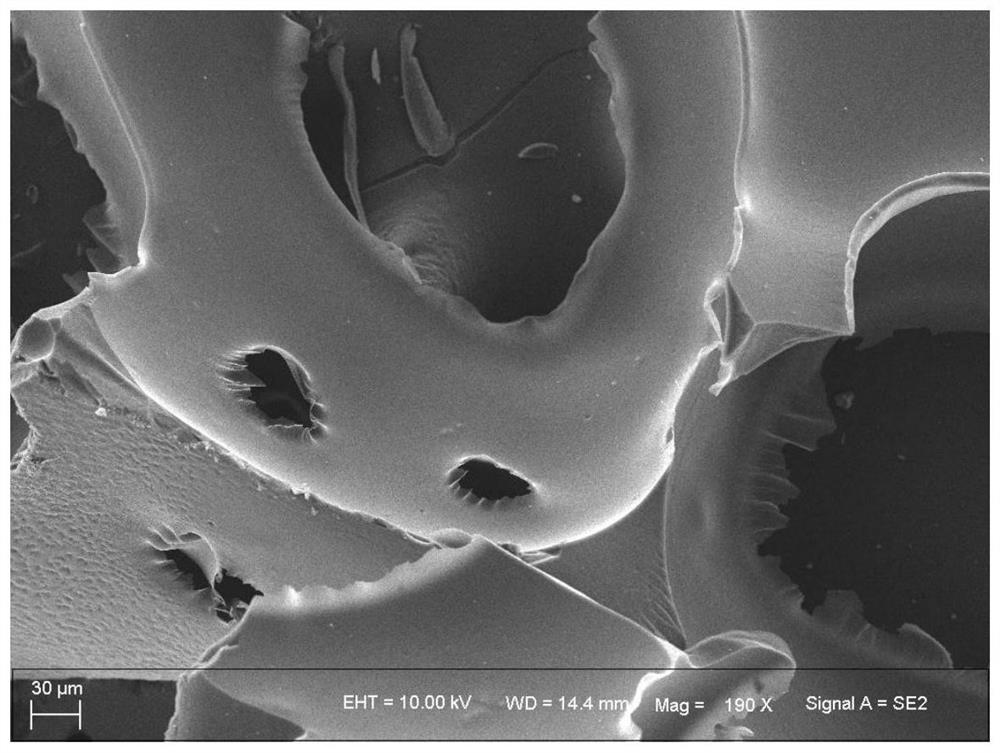

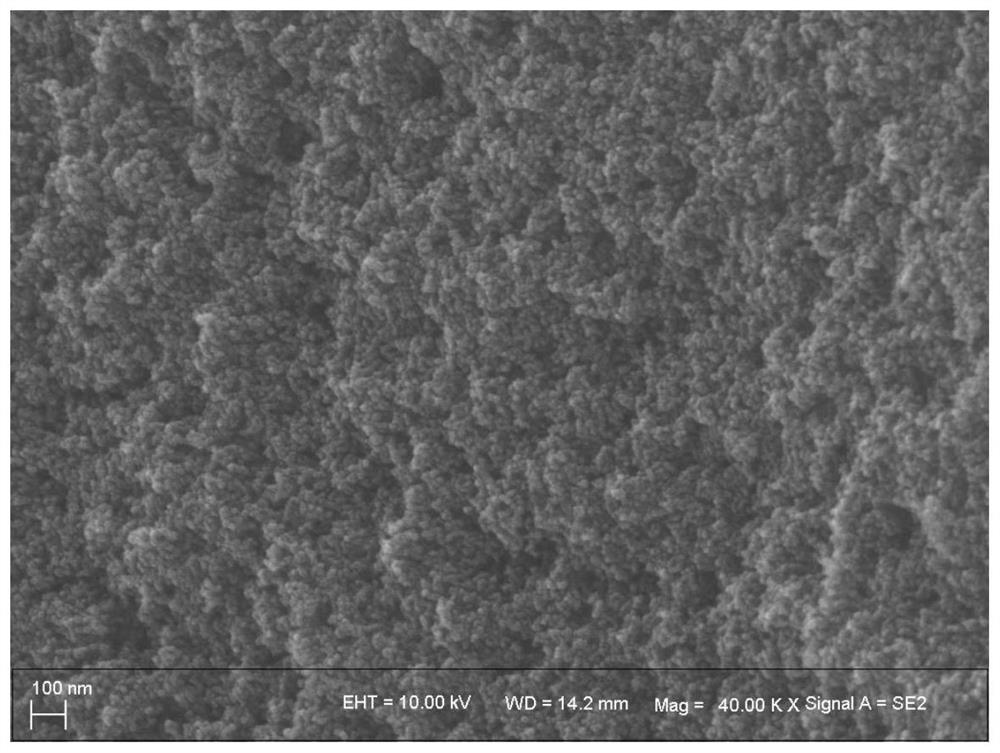

[0032] Such as Figure 1-5 As shown, the present embodiment provides a method for preparing a hierarchical porous carbon material, including: S1: after boiling, drying and grinding Galla galla to obtain Galla galla powder;

[0033] S2: mix the gallnut powder and water obtained in step S1 according to the mass ratio of 1:20 to obtain gallnut mixed liquid;

[0034] S3: Stir the gallnut mixed liquid obtained in step S2 at 30° C. for 1 hour, then centrifuge and filter to obtain gallnut precipitate;

[0035] S4: Mix the gallnut precipitate and water in step S3 according to the mass ratio of 1:20, then place it at 30° C. and stir for 1 hour to obtain the gallnut mixed solution, repeat 6 times;

[0036] S5: Place the gallnut mixed solution in step S4 in a lyophilized vacuum dryer for drying, mix with 40ml of water, and centrifuge to obtain a dark brown gallnut extract;

[0037] S6: Mix the gallnut extract in step S5 with the triblock polymer F-127 solution, wherein the mass ratio o...

Embodiment 2

[0040] This embodiment provides a method for preparing a hierarchically porous carbon material, including: S1: after boiling, drying and grinding gallnuts, gallnut powder is obtained;

[0041] S2: mix the gallnut powder and water obtained in step S1 according to the mass ratio of 1:20 to obtain gallnut mixed liquid;

[0042] S3: Stir the gallnut mixed liquid obtained in step S2 at 30° C. for 1 hour, then centrifuge and filter to obtain gallnut precipitate;

[0043] S4: Mix the gallnut precipitate and water in step S3 according to the mass ratio of 1:20, then place it at 30° C. and stir for 1 hour to obtain the gallnut mixed solution, repeat 6 times;

[0044] S5: Place the gallnut mixed solution in step S4 in a lyophilized vacuum dryer for drying, and then mix with 40ml of water to obtain a dark brown gallnut extract;

[0045] S6: Mix the Galla gall extract in step S5 with the triblock polymer F-127 solution, wherein the mass ratio of the Gallnut extract solution, F-127, and w...

Embodiment 3

[0048] This embodiment provides a method for preparing a hierarchically porous carbon material, including: S1: after boiling, drying and grinding gallnuts, gallnut powder is obtained;

[0049] S2: mix the gallnut powder and water obtained in step S1 according to the mass ratio of 1:20 to obtain gallnut mixed liquid;

[0050] S3: Stir the gallnut mixed liquid obtained in step S2 at 30° C. for 1 hour, then centrifuge and filter to obtain gallnut precipitate;

[0051] S4: Mix the gallnut precipitate and water in step S3 according to the mass ratio of 1:20, then place it at 30° C. and stir for 1 hour to obtain the gallnut mixed solution, repeat 6 times;

[0052] S5: Place the gallnut mixed solution in step S4 in a lyophilized vacuum dryer for drying, mix with 40ml of water, and centrifuge to obtain a dark brown gallnut extract;

[0053] S6: Mix the Galla gall extract in step S5 with the triblock polymer F-127 solution, wherein the mass ratio of the Gallnut extract solution, F-127...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com