Method and process system for preparing gasoline and diesel oil by co-hydrogenating coal tar and biomass oil

A process system and biomass technology, applied in the field of coal chemical processing and utilization, can solve the problems of incapable of large-scale production, difficult quality control, high hydrogen consumption of hydrogenation reaction, etc., so as to increase the efficiency of co-hydrogenation reaction, reduce the damage of equipment, The effect of low hydrogenation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

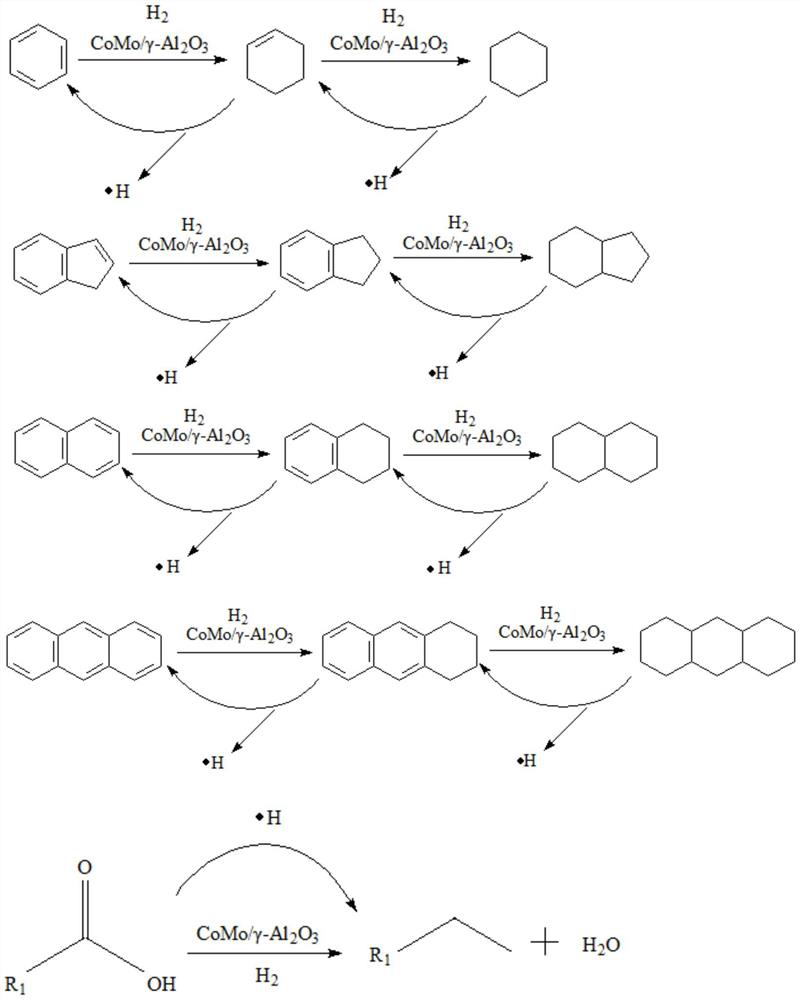

Method used

Image

Examples

Embodiment 1

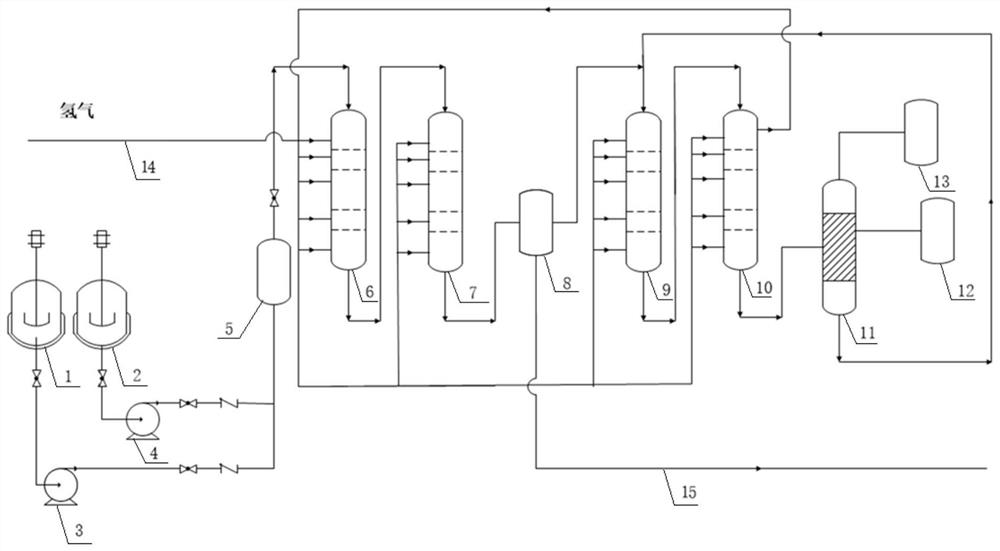

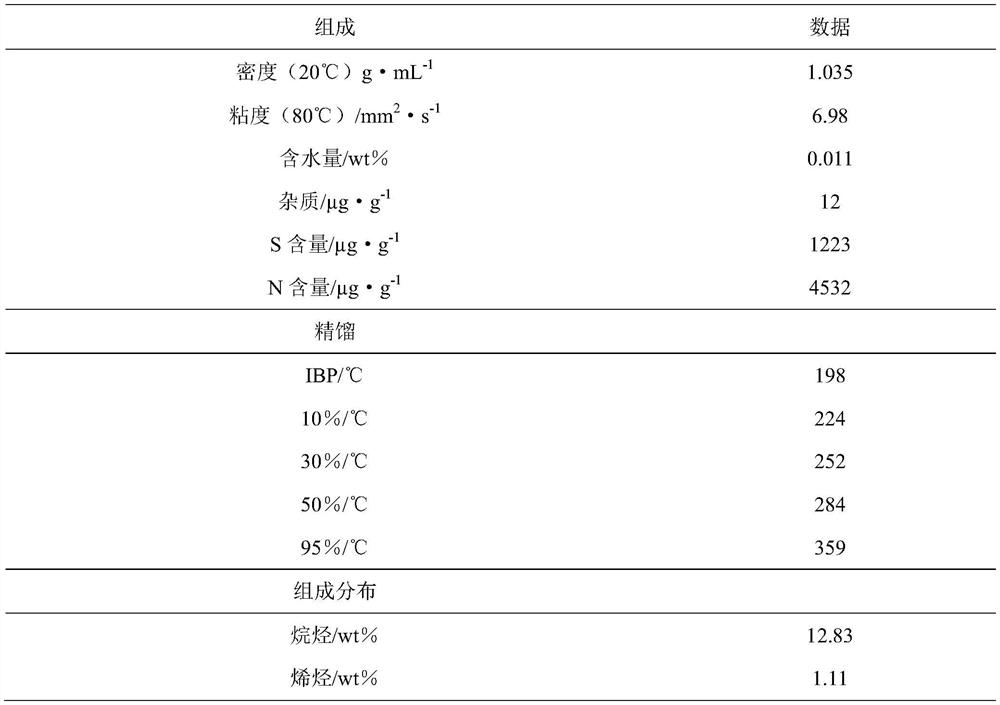

[0152] Take 7.2×10 4 Take t / a (10t / h) co-hydrogenation of coal tar and biomass oil as an example, hydrogenation can produce gasoline and diesel oil. Coal tar and biomass oil are mixed into the hydrofinishing unit. The process conditions of the hydrofinishing unit are shown in Table 2 to Table 5. The oil produced by hydrofinishing is separated to obtain hydrofined diesel oil and hydrofined gasoline rich in a large amount of saturated aromatics.

[0153] In this embodiment, coal tar and biomass oil are mixed as fixed-bed hydrocracking mixed raw materials, and the hydrocracking process adopts the above-mentioned method: coal tar and biomass oil co-hydrogenate, and the steps are as follows:

[0154] a. Coal tar and biomass oil mixing step: Coal tar and biomass oil with a feed flow ratio of 5:5 are mixed uniformly under stirring conditions of 80°C to 200°C to obtain raw materials.

[0155] b. The raw material produced in the mixing tank 5 enters the fixed-bed reactor I6 through a ...

Embodiment 1

[0157] Based on Example 1, the feed flow ratio was adjusted to 4:6, and the conditions of each reactor were changed to temperature (220, 320, 350, 350)°C, reaction pressure 9MPa, and total space velocity 0.3h -1 , The volume ratio of hydrogen to oil is 1700:1, and diesel and gasoline with a saturated aromatic content of 89.196% are produced.

[0158] Compared with Example 1, after changing feed ratio, temperature, pressure, space velocity and hydrogen-oil volume ratio, the obtained product is better than Example 1.

Embodiment 3

[0160] Based on Example 1, the feed flow ratio was adjusted to 3:7, and the conditions of each reactor were changed to temperature (240, 330, 360, 360)°C, reaction pressure 10MPa, and total space velocity 0.35h -1 , The volume ratio of hydrogen to oil is 1500:1, and diesel and gasoline with a saturated aromatic content of 91.01% are produced.

[0161] Compared with Example 1, after changing feed ratio, temperature, pressure, space velocity and hydrogen-oil volume ratio, the obtained product is better than Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com