Foam type toilet cleaner composition and preparation method thereof

A technology of composition and toilet cleaning liquid, applied in the directions of detergent composition, organic cleaning composition, cleaning composition solvent, etc., to achieve the effects of improving detergency, increasing the amount of foam, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

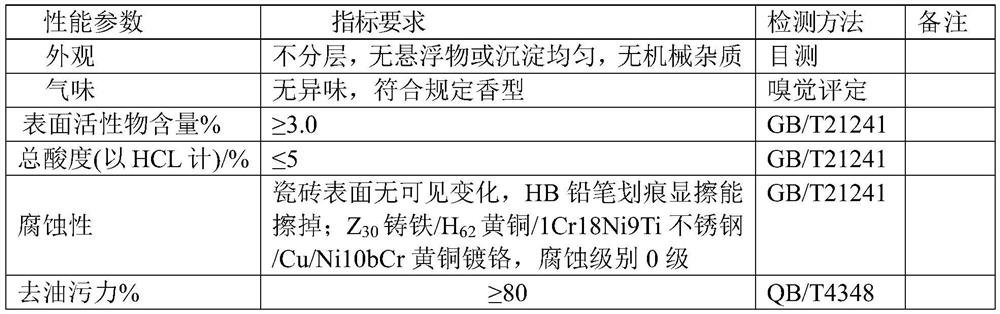

[0046] The invention discloses a foam type toilet cleaner composition and a preparation method thereof. This foam type toilet cleanser composition comprises the raw material component of following percentage by weight:

[0047] Chelating agent 0.02-1% (preferred range 0.2-0.8%); branched fatty alcohol polyoxyethylene ether nonionic surfactant 0.5-5% (preferred range 1-3%); alkyl glycoside nonionic surfactant Agent 2-10% (preferred range 5-8%); cationic surfactant CQ100S0.5-5% (preferred range 1-3%); dispersant 0.5-8% (preferred range 1-5%); environmental solvent 0-3% (preferably range 0.2-1.5%); polymer film-forming brightener 0.02-1% (preferably range 0.2-0.8%); organic acid 1-10% (preferably range 3-7%); other components 0-1% (preferred range 0.2-0.8%); water 65-85% (balance).

[0048]Dosing according to the feeding order listed in the formula, at room temperature, add water with a weight ratio of 65-85% into the mixing mixing tank, and start stirring; add chelating agent ...

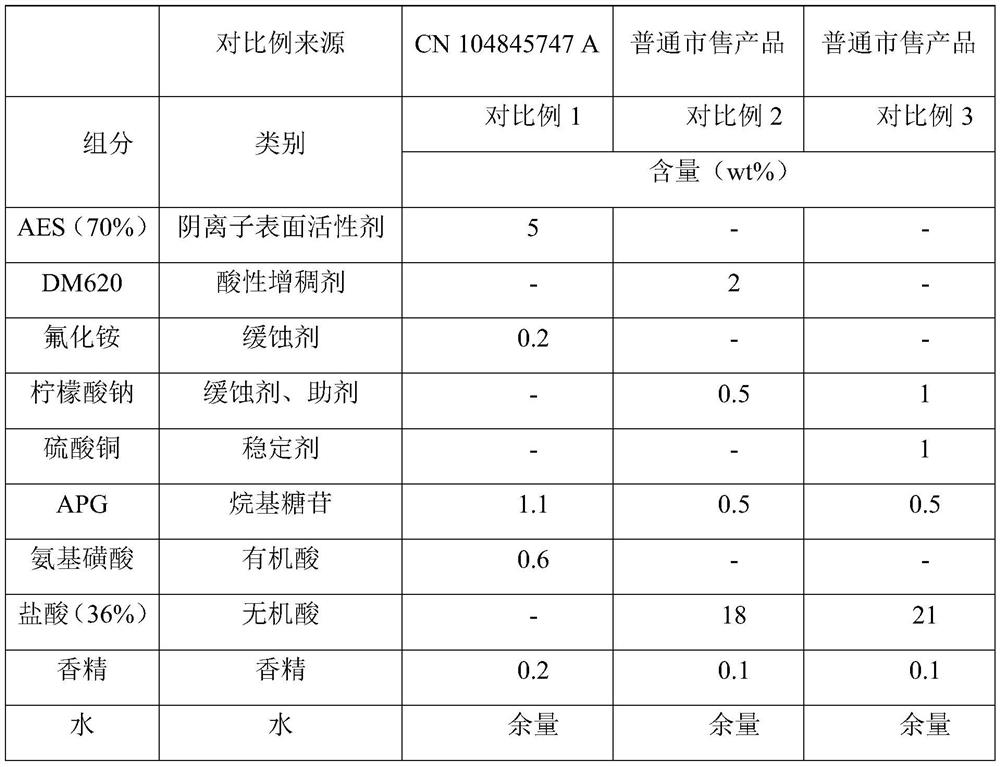

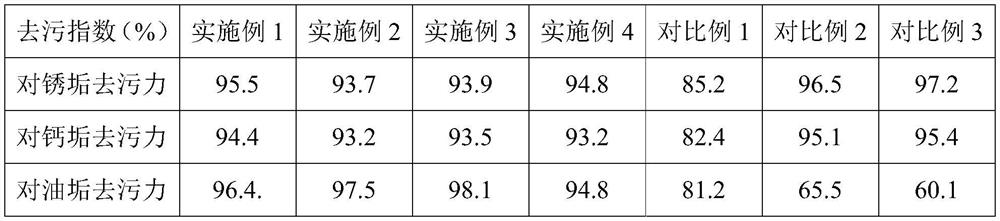

Embodiment 1-4

[0058] The following are respectively the formulation components and content descriptions of Examples 1-4, as shown in Table 1 below.

[0059] The formula component (weight percent %) of table 1 embodiment 1-4

[0060] Component category Example 1 Example 2 Example 3 Example 4 water 80.1% 79.9% 81.3% 81.4% Chelating agent 0.5% 0.3% 0.8% 0.2% Branched fatty alcohol polyoxyethylene ether 1% 1.5% 0.6% 1.2% Alkyl glycoside 7% 6% 8% 7% CQ100S 2% 2.5% 3% 1.5% Dispersant 3% 4% 2% 2.5% Environmentally friendly solvent 0.5% 1% 0.3% 0.6% polymer film-forming brightener 0.3% 0.2% 0.4% 0.5% citric acid 5.5% 4.5% 3.5% 5% other components 0.1% 0.1% 0.1% 0.1% total 100% 100% 100% 100%

[0061] The preparation process method of the foam type toilet cleaner composition of above-mentioned embodiment 1-4, comprises the following steps:

[0062] 1) Feed according to the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com