Galvanized sheet cleaning agent and preparation method thereof

A cleaning agent and galvanized sheet technology, which is applied in the field of industrial cleaning, can solve the problems of affecting the degreasing rate, slow cleaning speed, high degreasing and ash removal rate, etc., and achieve good chelating and dispersing effects, improved degreasing power, and easy rinsing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

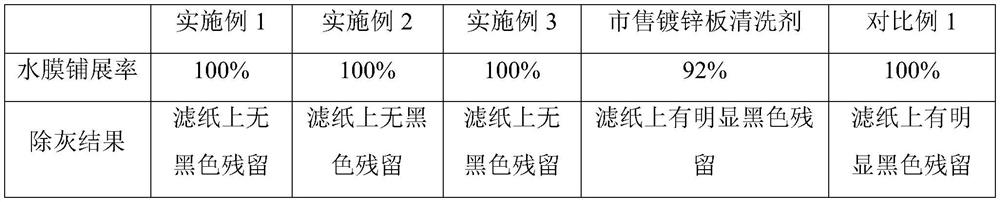

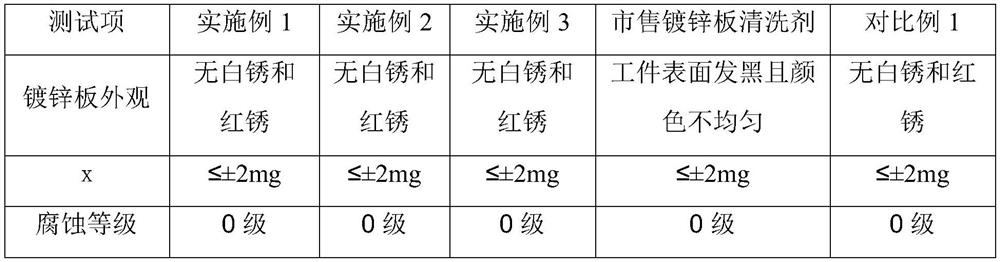

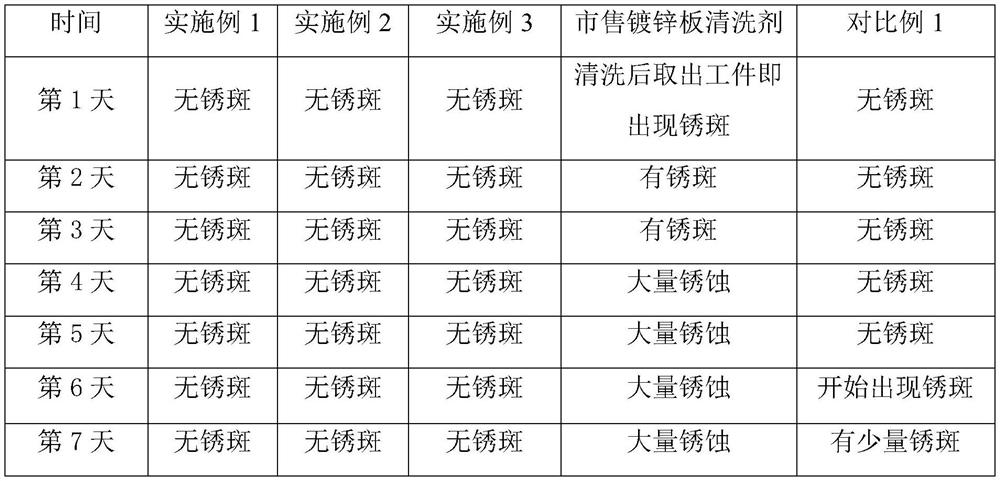

Examples

Embodiment 1

[0028] A cleaning agent for galvanized sheets, prepared from the following components by weight: 5 parts of tetrasodium edetate, 4 parts of potassium sodium tartrate, 3 parts of polyepoxysuccinic acid, 2 parts of methylene dinaphthalene Sodium sulfonate, 2 parts of coco polyoxyethylene ether (15) methyl ammonium chloride, 6 parts of decanol polyoxyethylene ether (5), 2 parts of isooctyl alcohol polyoxyethylene polyoxypropylene ether (6), 1.5 parts of styrene-acrylic acid copolymer, 3 parts of isohexanediol, 0.5 parts of rust inhibitor (dodecanedioic acid), 1.5 parts of triethanolamine, 69.5 parts of deionized water.

[0029] The preparation method of the galvanized sheet cleaning agent: add tetrasodium edetate, potassium sodium tartrate, polyepoxysuccinic acid, and sodium methylene dinaphthalene sulfonate successively to deionized water and continue stirring to obtain a mixed solution, and then Add coconut oil polyoxyethylene ether (15) methyl ammonium chloride, decanyl alcoho...

Embodiment 2

[0031] A cleaning agent for galvanized sheets, prepared from the following components by weight: 5 parts of tetrasodium edetate, 3.5 parts of potassium sodium tartrate, 2 parts of polyepoxysuccinic acid, 3.5 parts of methylene dinaphthalene Sodium Sulfonate, 1 Part of Coco Polyoxyethylene Ether (15) Methyl Ammonium Chloride, 7 Parts of Decyl Alcohol Polyoxyethylene Ether (5), 2 Parts of Isooctyl Alcohol Polyoxyethylene Polyoxypropylene Ether (6), 2 parts styrene-acrylic acid copolymer, 2 parts isohexanediol, 0.5 parts rust inhibitor (2,4,6-tris(aminocaproyl)-1,3,5-triazine), 1.5 parts triethanolamine, 70 parts deionized water.

[0032] The preparation method of the galvanized sheet cleaning agent is the same as that in Example 1. The galvanized sheet cleaning agent is a reddish-brown transparent liquid with a pH of 8.69.

Embodiment 3

[0034] A cleaning agent for galvanized sheets, prepared from the following components by weight: 8 parts of tetrasodium edetate, 1 part of potassium sodium tartrate, 1 part of polyepoxysuccinic acid, 2 parts of methylene dinaphthalene Sodium sulfonate, 2 parts of coconut oil polyoxyethylene ether (15) methyl ammonium chloride, 3 parts of decanol polyoxyethylene ether (5), 5 parts of isooctyl alcohol polyoxyethylene polyoxypropylene ether (6), 2 parts styrene-acrylic acid copolymer, 1 part isohexanediol, 0.5 parts rust inhibitor (sebacic acid), 1.5 parts triethanolamine, 73 parts deionized water.

[0035] The preparation method of the galvanized sheet cleaning agent is the same as that in Example 1. The galvanized sheet cleaning agent is a reddish-brown transparent liquid with a pH of 8.54.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com