Special traceable non-phosphorous corrosion and scale inhibitor for oxygen plant

A technology of corrosion and scale inhibitor, copper corrosion inhibitor, applied in descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc. The problem of chemical content, difficult to quickly analyze the content, etc., to achieve the effect of reducing the dosage of the chemical, excellent biodegradability, and preventing metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

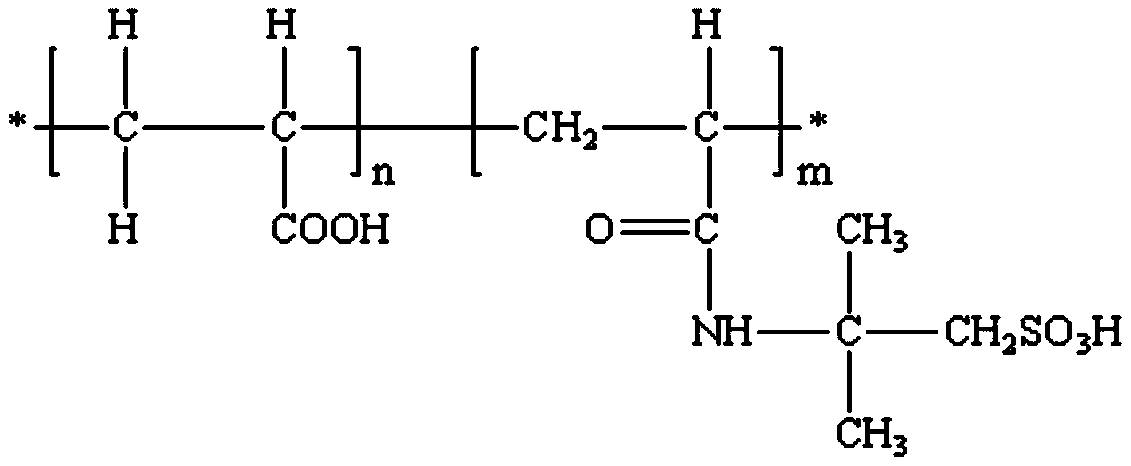

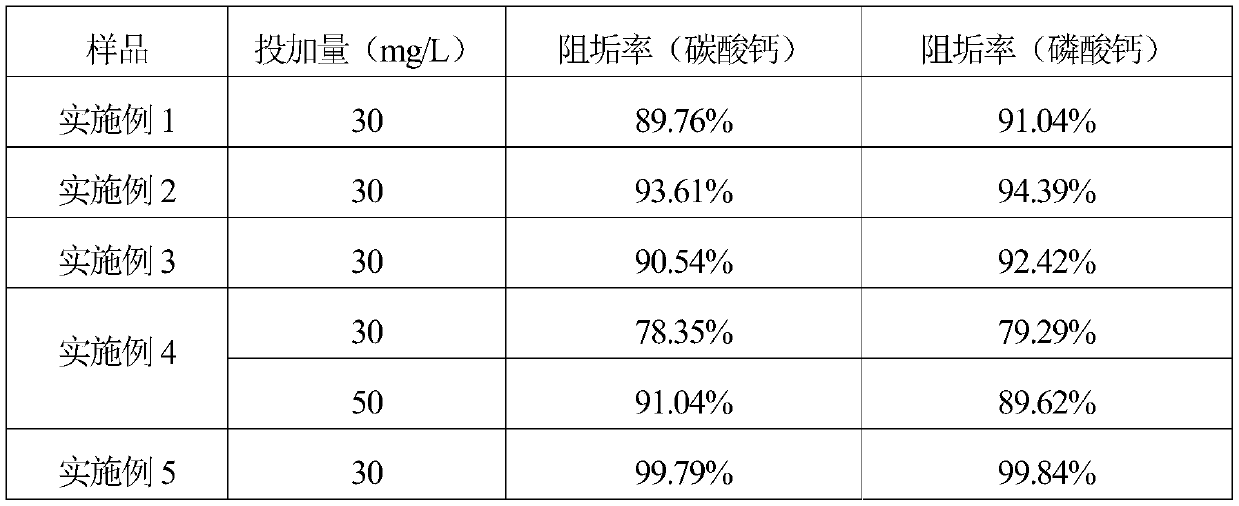

Embodiment 1

[0028] Add 590g of deionized water into the stirred tank and heat up to 90°C, add 40g of benzotriazole, 50g of zinc chloride, 20g of 1,3,6,8-pyrenetetrasulfonic acid tetrasodium salt in sequence, and start the stirrer for 80r / min and stir until the materials are all dissolved, cool down to normal temperature, add 200g carboxymethylthiosuccinic acid, 100g acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, stir at room temperature for 30min, and divide into packages to obtain Phosphorus-free traceable corrosion and scale inhibitor products for oxygen plants.

Embodiment 2

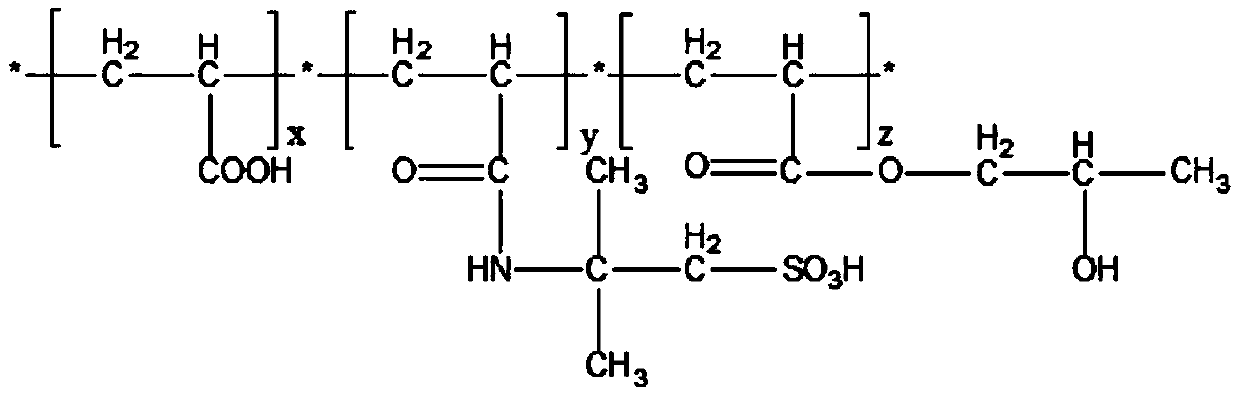

[0030] Add 340g of deionized water into the stirring tank and heat up to 90°C, then add 60g of mercaptobenzothiazole, 80g of zinc chloride, 20g of 1,3,6,8-pyrene tetrasulfonic acid tetrasodium salt, and start the stirrer 80r / Stir until the material is completely dissolved, cool down to normal temperature, add 300g carboxyethylthiosuccinic acid, 200g acrylic acid-2-acrylamide-2-methylpropanesulfonic acid-hydroxypropyl acrylate terpolymer, stir at room temperature for 30min , After subpackaging, the special phosphorus-free traceable corrosion and scale inhibitor products for oxygen plants can be obtained.

Embodiment 3

[0032] Add 535g of deionized water into the stirring tank and heat up to 90°C, then add 50g of mercaptobenzothiazole, 50g of zinc sulfate, 15g of 1,3,6,8-pyrene tetrasulfonic acid tetrasodium salt, and start the stirrer at 80r / min Stir until the material is completely dissolved, cool down to normal temperature, add 200g carboxymethyl thiosuccinic acid, 150g acrylic acid-acrylic acid ester-sulfonate copolymer TH-613, stir at room temperature for 30min, and then obtain the non- Phosphorus traceable corrosion and scale inhibitor products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com