A Method for Evaluating the Leaching Toxicity of Municipal Waste Incineration Fly Ash

A technology for waste incineration fly ash and incineration fly ash, which is applied in the fields of biochemical equipment and methods, color/spectral property measurement, and microbial determination/inspection, etc. security and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

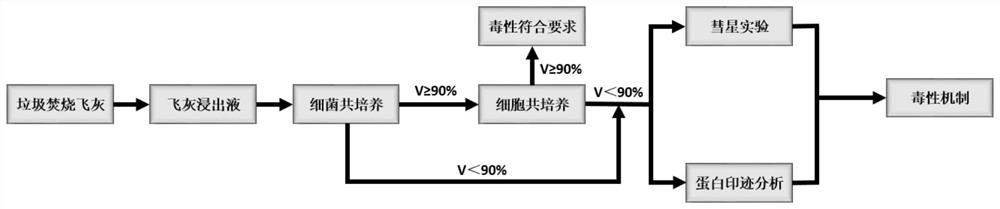

Method used

Image

Examples

Embodiment 1

[0045] S1. Dry the waste incineration fly ash samples from the same batch of waste incineration power plants at 105°C for 24 hours, and seal them for future use. The TCLP test results are shown in Table 1;

[0046] S2. Take concentrated sulfuric acid and concentrated nitric acid and mix them with a volume ratio of 2:1. After mixing evenly, add the mixed solution dropwise to deionized water to make the pH value to 4 to make an extraction agent;

[0047] S3. Weigh 10g of the sample obtained in step S1 and 100mL of the extraction agent obtained in step S2, shake and mix in a PE barrel, seal and fix it on a flipping oscillating device, turn and shake at a speed of 30rpm at room temperature for 18h, The resulting suspension was filtered through a 0.3 μm microporous membrane to obtain a leaching solution. The leaching solution was alkaline and had a pH value of 11;

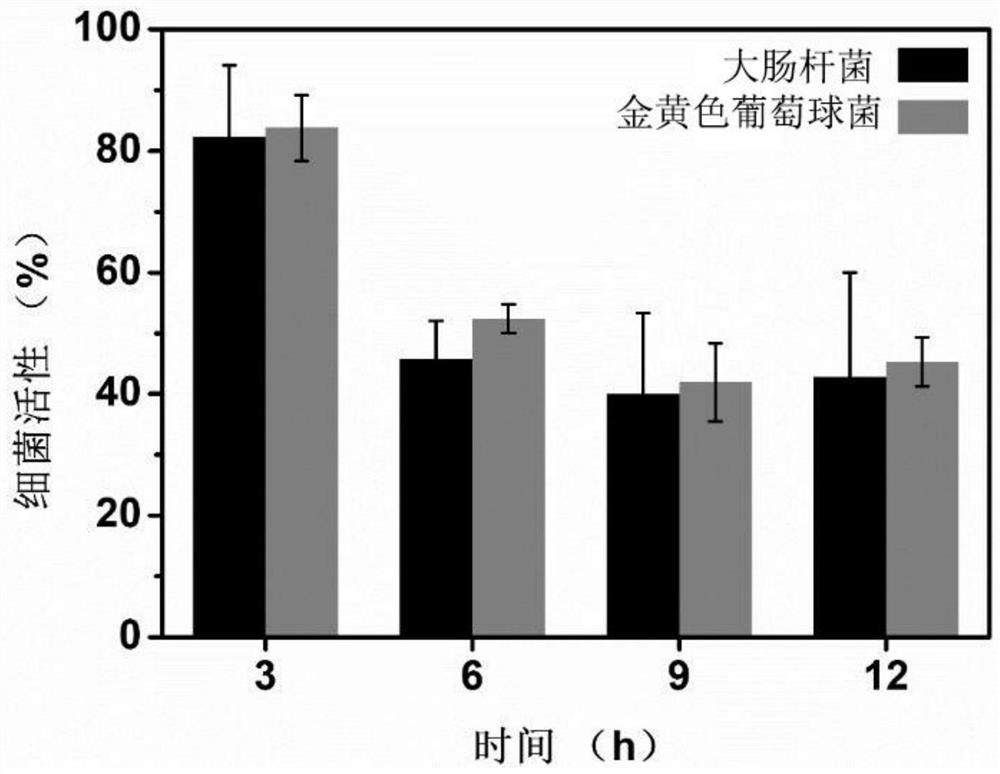

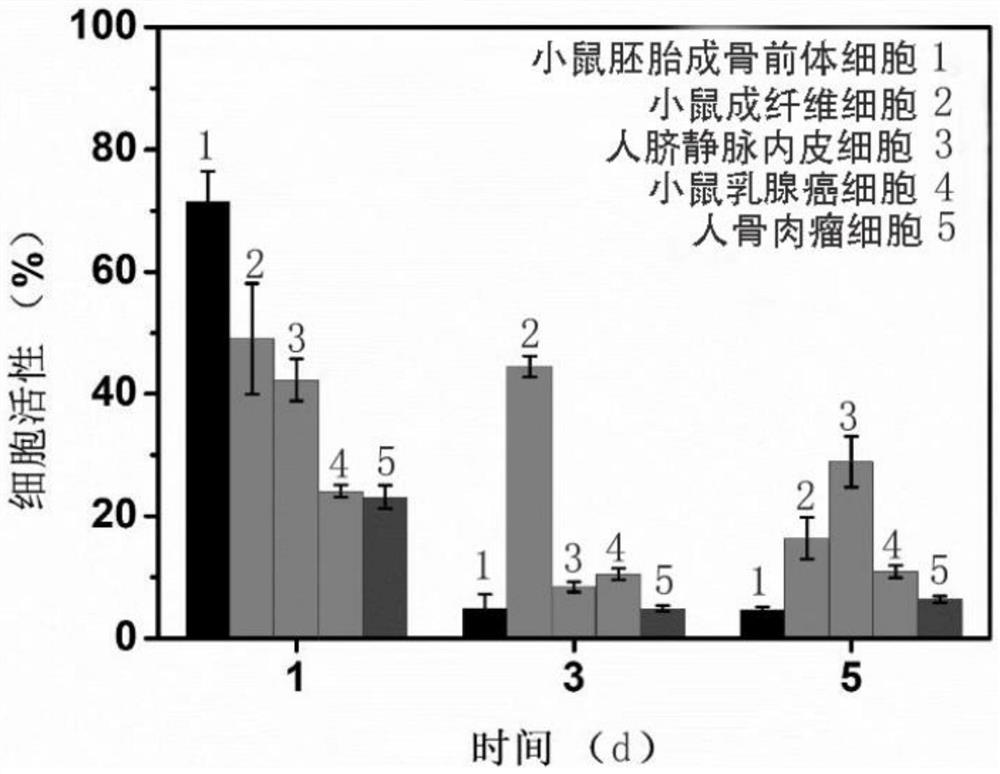

[0048] S4, the leachate that step S3 is obtained is acidified to pH 7.4, by adding 0.3g of beef extract, 1g of pepton...

Embodiment 2

[0070] S1. Dry the waste incineration fly ash sample from the same batch of waste incineration power plant at 105°C for 24 hours, and seal it for storage for later use. The TCLP toxicity test results of waste incineration fly ash are shown in Table 2;

[0071] S2. Take concentrated sulfuric acid and concentrated nitric acid and mix them with a volume ratio of 2:1. After mixing evenly, add the mixed solution dropwise to deionized water to make the pH value to 3 to make an extraction agent;

[0072] S3. Weigh 10g of the sample obtained in step S1 and 100mL of the extraction agent obtained in step S2, shake and mix in a PE barrel, seal and fix it on an inverting oscillating device, and invert and oscillate at a speed of 40rpm for 18h at room temperature, The resulting suspension was filtered through a 0.4 μm microporous membrane to obtain a leaching solution. The leaching solution was alkaline and had a pH value of 12;

[0073] S4, the leachate that step S3 is obtained is by acid...

Embodiment 3

[0095] S1. Dry the waste incineration fly ash samples from the same batch of waste incineration power plants at 105°C for 24 hours, and seal them for future use. The TCLP test results are shown in Table 3;

[0096] S2. Take concentrated sulfuric acid and concentrated nitric acid and mix them with a volume ratio of 2:1. After mixing evenly, add the mixed solution dropwise to deionized water to make the pH value reach 5 to make an extraction agent;

[0097] S3. Weigh 10g of the sample obtained in step S1 and 100mL of the extraction agent obtained in step S2, shake and mix in a PE barrel, seal and fix it on a flipping oscillating device, turn and shake at a speed of 30rpm at room temperature for 18h, The resulting suspension was filtered through a 0.5 μm microporous membrane to obtain a leaching solution. The leaching solution was alkaline and had a pH value of 12;

[0098] S4, the leachate that step S3 is obtained is by acidifying to pH 7.4, by adding 0.3g beef extract, 1g pepto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com