High-strength electrical steel for high-speed motor and preparation method of high-strength electrical steel

A high-speed motor, high-strength technology, used in manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of high iron loss, increased iron loss, and reduced size, achieving high strength, low cost, and low iron loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high-strength electrical steel for high-speed motors and a preparation method thereof. The preparation method described in this embodiment is:

[0035] The chemical composition of the high-strength electrical steel for high-speed motors is: Si is 3.2wt%; Mn is 0.5wt%; Als is 0.8wt%; Cr is 1.0wt%; Sn is 0.03wt%; P≤0.02wt%; N≤0.003wt%; S<0.003wt%; C<0.003wt%; the rest is Fe and unavoidable impurities.

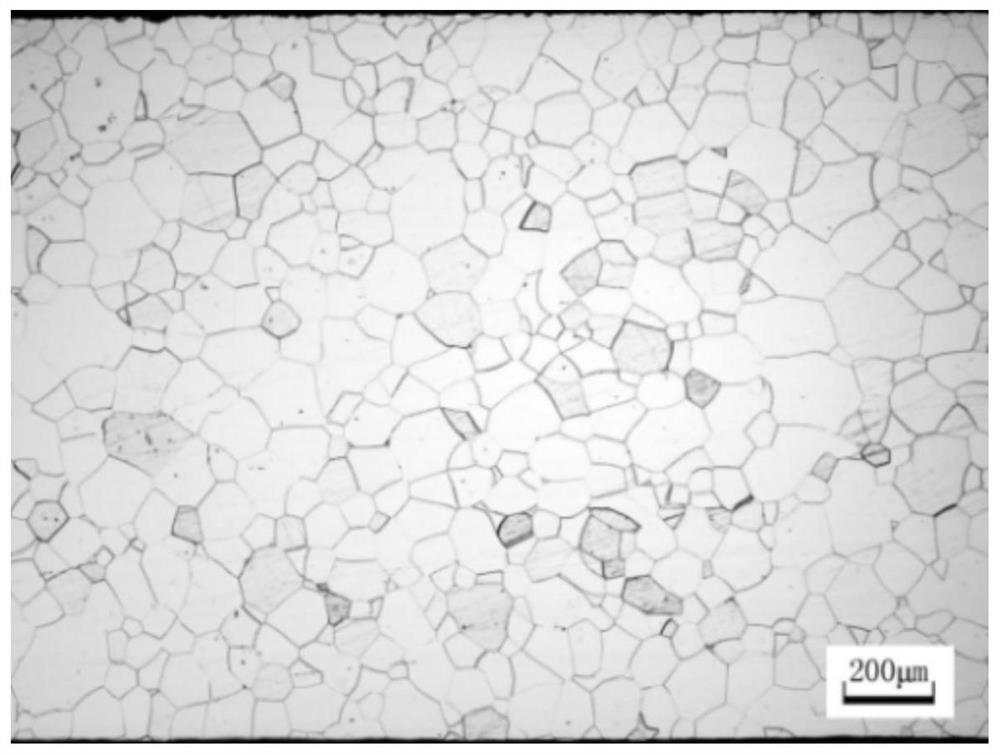

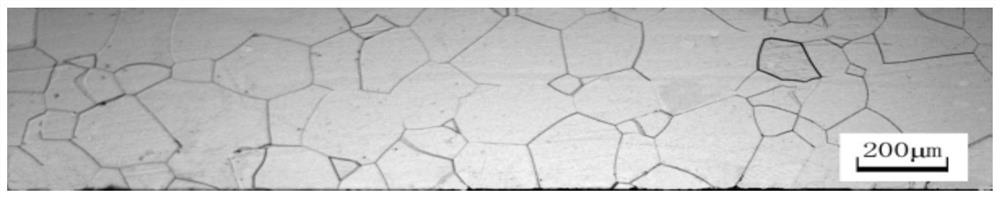

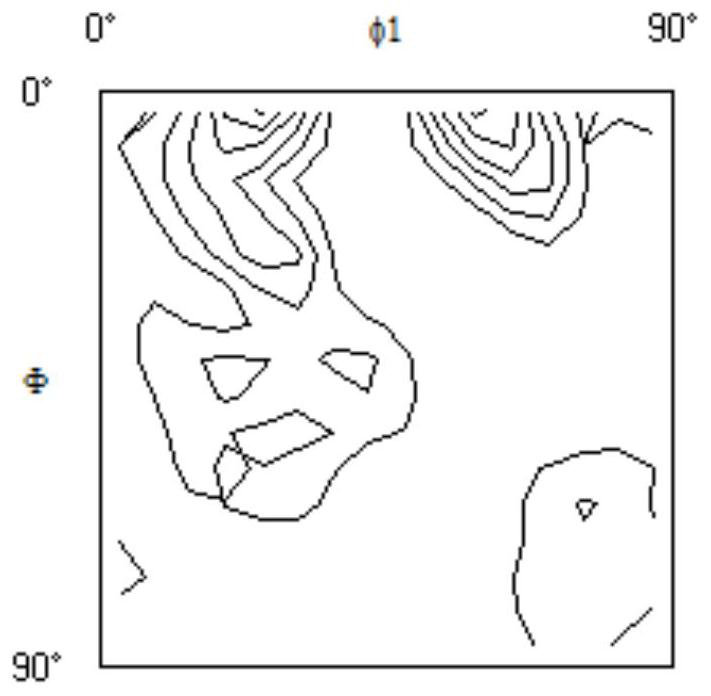

[0036] Smelting according to the chemical composition of the high-strength electrical steel for high-speed motors, casting it into a slab at 1490°C, keeping the slab at 1100°C for 2 hours, and hot rolling it to a hot-rolled plate with a thickness of 1.8mm, The final rolling temperature is 800°C; the hot-rolled sheet is then normalized at 920°C for 4 minutes to obtain a normalized sheet with a uniform structure; the normalized sheet is pickled and then cold-rolled once, and the cold-rolled press 83% to obtain a cold-rolled sheet with a thickness of 0.3 mm; finally, the co...

Embodiment 2

[0040] A high-strength electrical steel for high-speed motors and a preparation method thereof. The preparation method described in this embodiment is:

[0041] The chemical composition of the high-strength electrical steel for high-speed motors is: Si is 3.0wt%; Mn is 1.1wt%; Als is 0.9wt%; Cr is 1.8wt%; Sn is 0.02wt%; Ce is 0.02wt%; P≤0.02wt%; N≤0.003wt%; S<0.003wt%; C<0.003wt%; the rest is Fe and unavoidable impurities.

[0042] Smelting according to the chemical composition of high-strength electrical steel for high-speed motors, casting into slabs at 1500°C, keeping the slabs at 1130°C for 1.5h, and hot-rolling to a hot-rolled plate with a thickness of 2mm, The final rolling temperature is 850°C; the hot-rolled sheet is then normalized at 940°C for 3 minutes to obtain a normalized sheet with a uniform structure; the normalized sheet is pickled and then cold-rolled once, and the cold-rolled press The amount is 84%, and the cold-rolled sheet with a thickness of 0.32mm is ...

Embodiment 3

[0046] A high-strength electrical steel for high-speed motors and a preparation method thereof. The preparation method described in this embodiment is:

[0047] The chemical composition of the high-strength electrical steel for high-speed motors: Si is 3.5wt%; Mn is 0.9wt%; Als is 0.5wt%; Cr is 0.06wt%; Sn is 0.05wt%; Ce is 0.03wt%; ≤0.02wt%; N≤0.003wt%; S<0.003wt%; C<0.003wt%; the rest is Fe and unavoidable impurities.

[0048] According to the chemical composition of the high-strength electrical steel for high-speed motors, it is smelted and cast into slabs at 1550°C. The slabs are kept at 1200°C for 1 hour and hot-rolled to a hot-rolled plate with a thickness of 2.5mm. The final rolling temperature is 900°C; the hot-rolled sheet is then normalized at 960°C for 2 minutes to obtain a normalized sheet with a uniform structure; the normalized sheet is pickled and then cold-rolled once, and the cold-rolled press 75% to obtain a cold-rolled sheet with a thickness of 0.35 mm; fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com