Preparation method of ODS metal film material

A technology of metal thin film and ODS, which is applied in the field of preparation of ODS metal thin film materials, can solve problems such as coarse grains of metal blocks, and achieve the effect of simple preparation process, easy operation and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

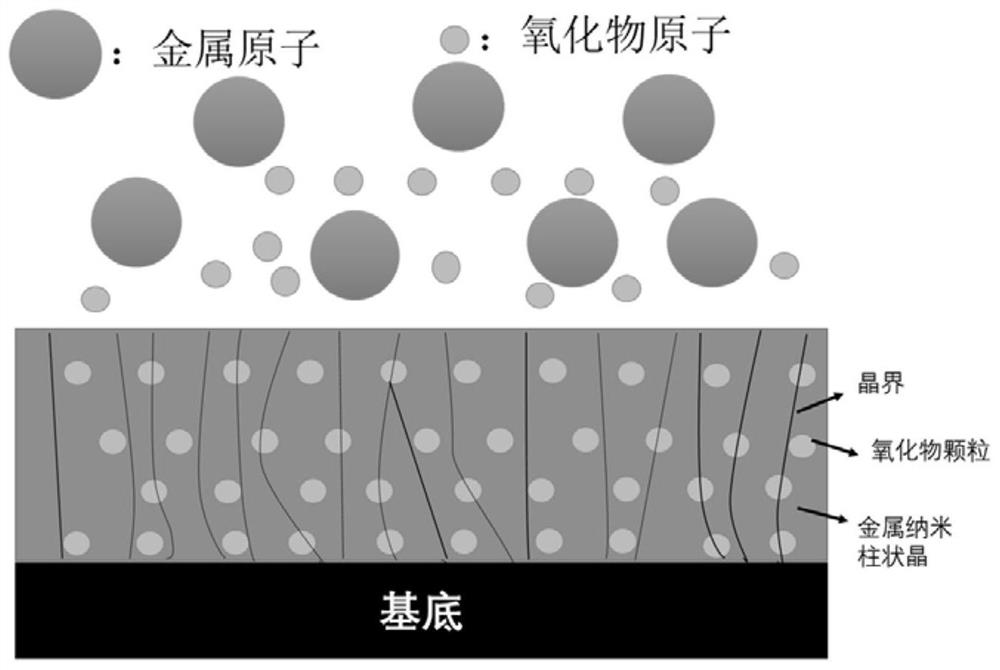

[0038] Such as figure 1 with figure 2 Shown, a kind of preparation method of ODS metal film material comprises the following steps:

[0039] Step 1: Take Y with an average particle size of about 50nm 2 o 3 The powder is about 2g, put it in a sleeve mold with an inner diameter of 20mm, and press it into a disc with a diameter of 20mm and a thickness of 2mm with a tablet press. The tablet pressing condition is 15MPa and the pressure is maintained for 5min. Furnace heated to 1300 o C, keep warm for 5h, cool down with the furnace, and then get Y 2 o 3 Ceramics;

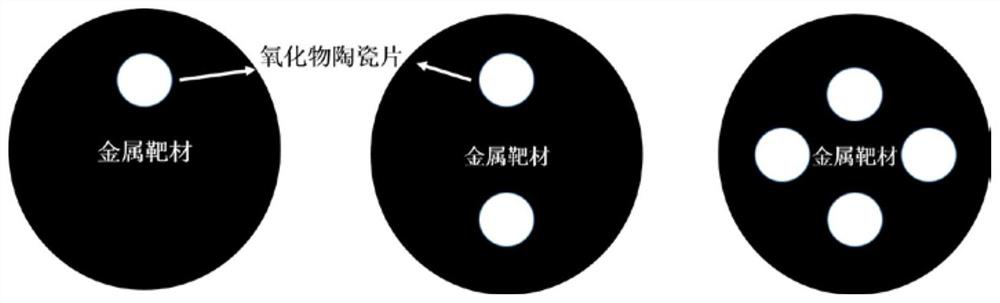

[0040] Step 2: Surface treatment is carried out on the 304 stainless steel metal target with a thickness of 4mm to remove the surface metal oxides and impurities to obtain the metal target; the metal target is cut into two sets of symmetrical through holes, and the Y 2 o 3 The ceramic sheet is covered with conductive adhesive on the back of the metal target, and two Ys must be added 2 o 3 Composite target of ce...

Embodiment 1 and comparative example 1

[0052] The extended test of embodiment 1 and comparative example 1:

[0053] 1) First examine Y 2 o 3 The effect of the number of ceramic flakes on the oxide concentration in the film:

[0054] According to steps one to four in Example 1, without changing other parameters, only change the Y loaded on the 304 stainless steel target 2 o 3 The number of ceramic sheets, the number is 0, 1, 2, 4 in turn, and the Y content in the corresponding film is measured by inductively coupled plasma spectrometer (ICP) to be about 0, 0.07, 0.15, 1.02 at%, and the Y content in the film With mosaic Y 2 o 3 The increase of the slice increases accordingly.

[0055] 2) Next, examine Y 2 o 3 The effect of the number of ceramic sheets on the film deposition thickness:

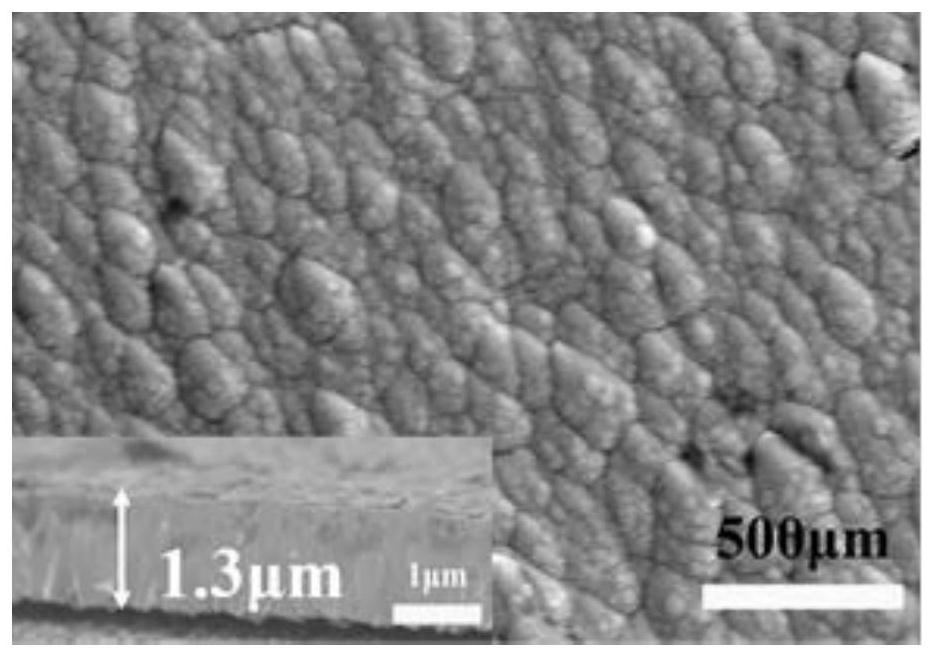

[0056] Under the same process conditions and sputtering conditions, the target load Y 2 o 3 The number of ceramic sheets is 0 and 2 in turn, and the thickness of the film is about 2.5 μm and 1.3 μm respectively, indicating ...

Embodiment 2

[0060] Compared with Example 1, the process parameters in Steps 1, 3 and 4 are the same, the difference is that the composite target used in Step 2 is added with four Y 2 o 3 The W target material of the ceramic sheet; the surface morphology analysis and cross-sectional morphology analysis of the obtained film are shown in Figure 4(a), the thickness of the film is about 1 μm, and the Y in the film material 2 o 3 The research on the distribution of is shown in Fig. 4(b), the Y 2 o 3 The particle size is about 60nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com