Preparation method of efficient composite wave-absorbing material ZIF-67atCNTs

A ZIF-67, composite wave absorbing material technology, applied in chemical instruments and methods, metal material coating technology, carbon compounds, etc., can solve the problems of poor corrosion resistance, high density of metal particles, limiting the application of high-performance aircraft, etc. achieve the effect of reducing the density of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

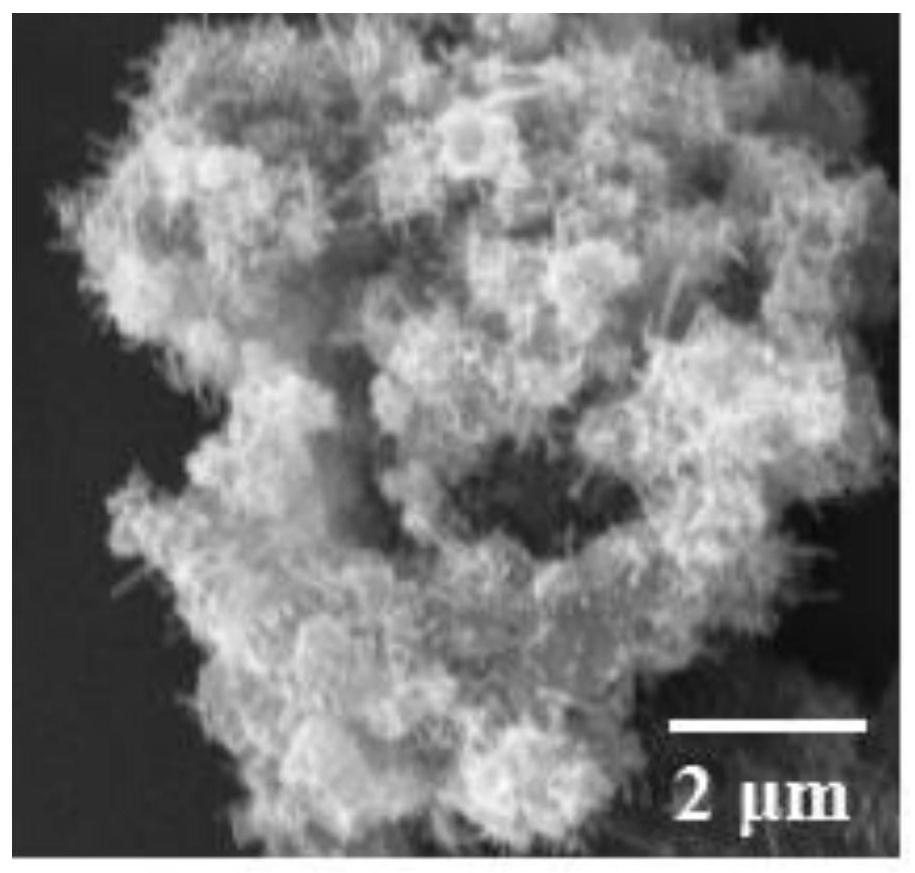

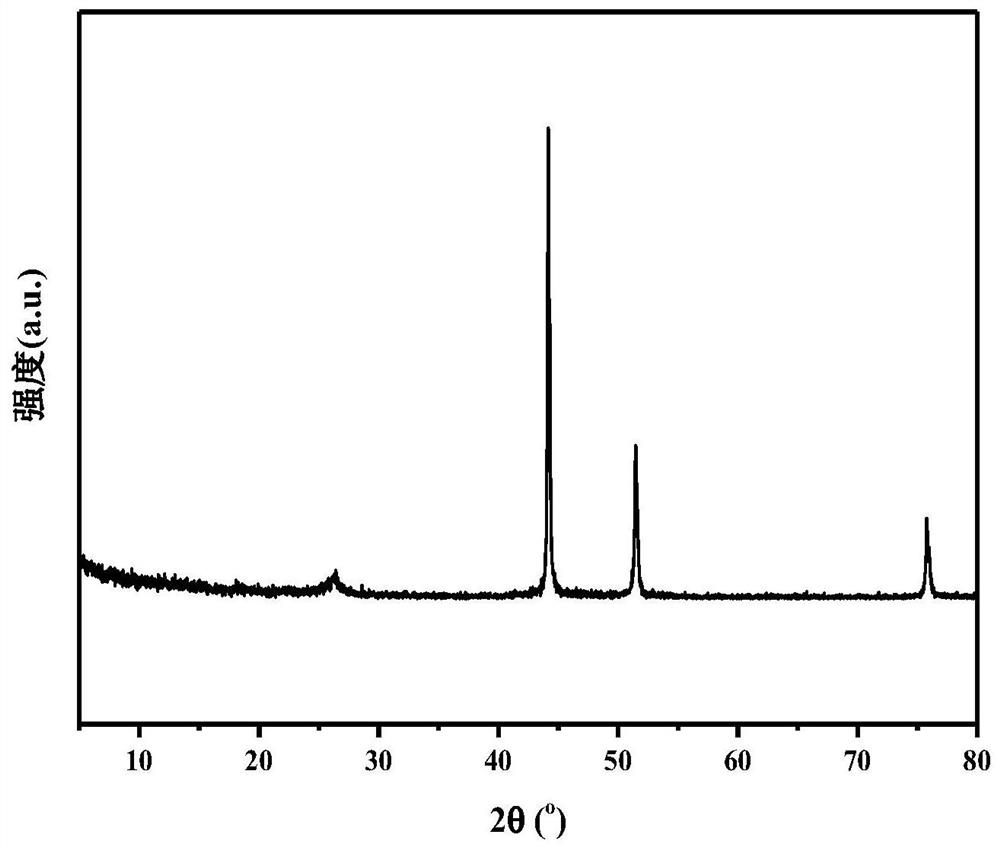

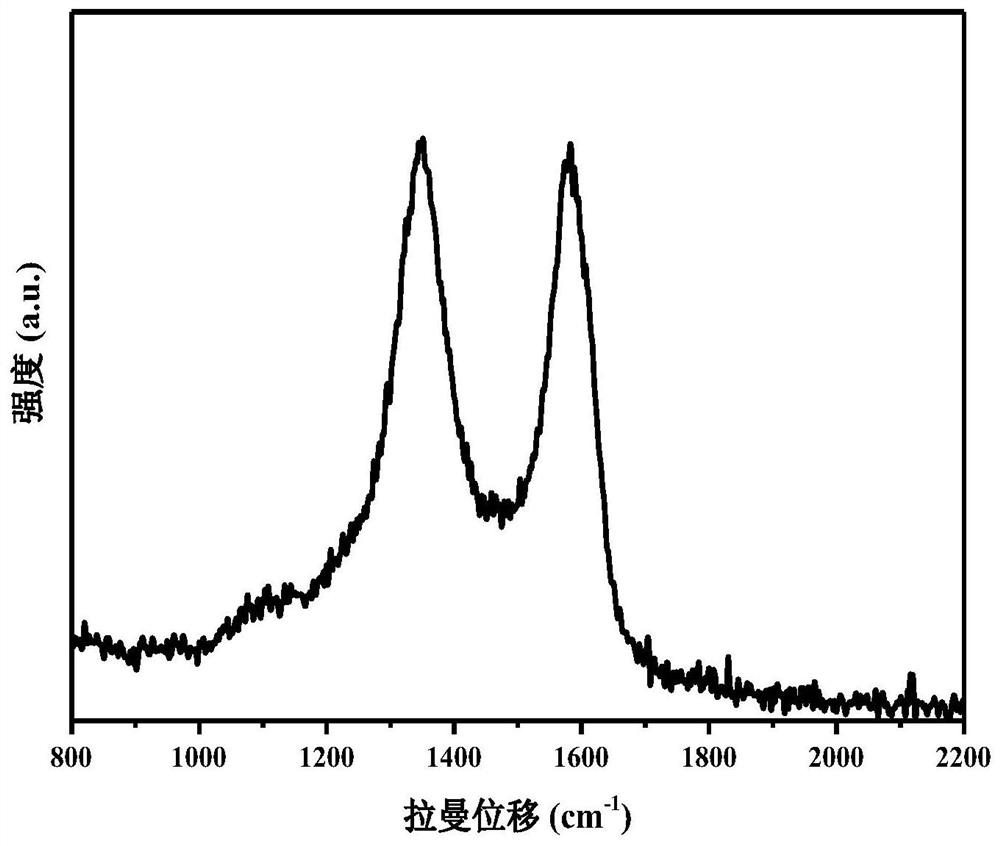

[0022] Example 1 A preparation method of high-efficiency composite wave-absorbing material ZIF-67@CNTs-1

[0023] (1) Preparation of ZIF-67;

[0024] 0.6g PVP, 1.8g (CoNO 3 ) 2 ·6H 2 O, 40mL methanol ultrasonic stirring 60min is recorded as solution 1 (PVP: 0.015g / ml methanol; PVP: (CoNO 3 ) 2 ·6H 2 O=1:3); 2.4g DMI was dissolved in 40ml methanol (DMI: 0.06g / ml methanol), ultrasonically stirred for 60min and recorded as solution 2, 40ml solution 2 was added dropwise to solution 1, and after mechanical stirring for 4h, Stand at room temperature for 48h, wash with ethanol / water solution, and dry in vacuo to obtain the intermediate ZIF-67.

[0025] (2) ZIF-67 / C 3 N 6 h 6 preparation of

[0026] Dry 1.0g ZIF-67 in a vacuum oven at 60°C for 12h, then add 1.0g C 3 N 6 h 6 , fully ground, mixed evenly, the obtained powder product is ZIF-67 / C 3 N 6 h 6 .

[0027] (3) Preparation of ZIF-67@CNTs-1

[0028] ZIF-67-C 3 N 6 h 6 The powder is calcined at 700°C for 2 hou...

Embodiment 2

[0034] Example 2 A preparation method of high-efficiency composite wave-absorbing material ZIF-67@CNTs-2

[0035] (1) Preparation of ZIF-67;

[0036] 0.6g PVP, 0.6g (CoNO 3 ) 2 ·6H 2 O, 60mL methanol ultrasonic stirring 10min is recorded as solution 1 (PVP: 0.01g / ml methanol; PVP: (CoNO 3 ) 2 ·6H 2 O=1:1); 3.0g DMI was dissolved in 150ml methanol (DMI: 0.02g / ml methanol), ultrasonically stirred for 10min and recorded as solution 2, 150ml solution 2 was added dropwise to solution 1, and after mechanical stirring for 8h, Stand at room temperature for 12 h, wash with ethanol / water solution, and dry in vacuo to obtain the intermediate ZIF-67.

[0037] (2) ZIF-67-C 3 N 6 h 6 preparation of

[0038] Dry 1.0g ZIF-67 in a vacuum oven at 60°C for 12h, then add 5.0g C 3 N 6 h 6 , fully ground, mixed evenly, the obtained powder product is ZIF-67 / C 3 N 6 h 6 .

[0039] (3) Preparation of ZIF-67-CNTs-2:

[0040] ZIF-67-C 3 N 6 h 6 The powder is calcined at 600°C for 4 ...

Embodiment 3

[0041] Example 3 A preparation method of high-efficiency composite wave-absorbing material ZIF-67@CNTs-3

[0042] (1) Preparation of ZIF-67;

[0043] 0.6g PVP, 1.5g (CoNO 3 ) 2 ·6H 2 O, 30mL methanol ultrasonic stirring 30min is recorded as solution 1 (PVP: 0.02g / ml methanol; PVP: (CoNO 3 ) 2 ·6H 2 O=1:4); 1.0g DMI was dissolved in 50ml methanol (DMI: 0.02g / ml methanol), ultrasonically stirred for 30min and recorded as solution 2, 50ml solution 2 was added dropwise to solution 1, and after mechanical stirring for 6h, Stand at room temperature for 24 h, wash with ethanol / water solution, and dry in vacuo to obtain the intermediate ZIF-67.

[0044] (2) ZIF-67-C 3 N 6 h 6 preparation of

[0045] Dry 1.0g ZIF-67 in a vacuum oven at 60°C for 12h, then add 3.0g C 3 N 6 h 6 , fully ground, mixed evenly, the obtained powder product is ZIF-67 / C 3 N 6 h 6 . .

[0046] (3) Preparation of ZIF-67-CNTs-3

[0047] ZIF-67-C 3 N 6 h 6 In a tube furnace, calcined at 900 °C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com