Radio frequency soi structure and preparation method thereof

A technology of radio frequency and isolation structure, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficult to effectively realize the integration of digital circuits, analog circuits and radio frequency circuits, and reduce impurity pollution and circuit The effect of reducing crosstalk between substrates and reducing substrate coupling noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

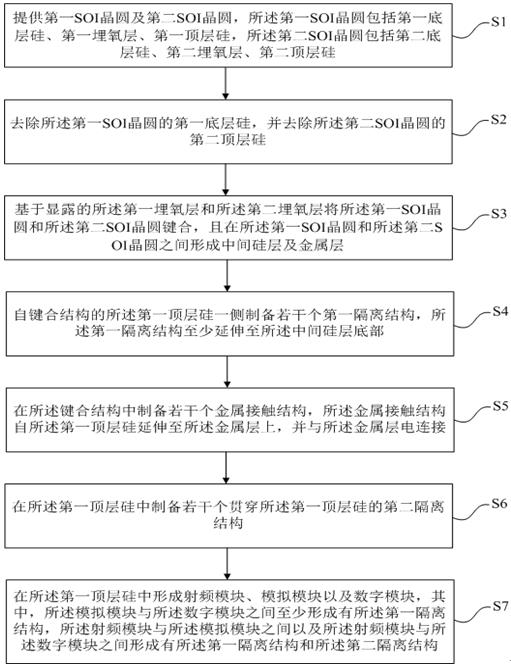

[0048] Such as figure 1 Shown, the present invention provides a kind of preparation method of radio frequency SOI structure, and described preparation method comprises the following steps:

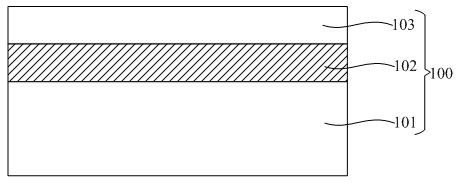

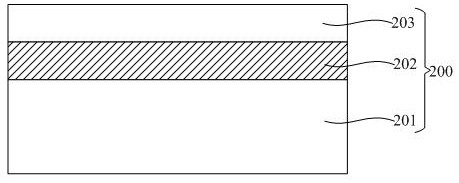

[0049] S1, providing a first SOI wafer and a second SOI wafer, the first SOI wafer includes a first bottom layer of silicon, a first buried oxide layer, and a first top layer of silicon, and the second SOI wafer includes a second bottom layer Silicon, a second buried oxide layer, and a second top layer of silicon;

[0050] S2, removing the first underlying silicon of the first SOI wafer, and removing the second top silicon of the second SOI wafer;

[0051] S3, bonding the first SOI wafer to the second SOI wafer based on the exposed first buried oxide layer and the second buried oxide layer, and bonding the first SOI wafer to the second SOI wafer Forming an intermediate silicon layer and a metal layer between the second SOI wafers;

[0052] S4, preparing several first isolation structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com