Film with heat dissipation structure and manufacturing method thereof

A technology of heat dissipation structure and manufacturing method, which is applied in the direction of coating, electrical components, circuits, etc., can solve the problems of low heat conduction efficiency and large space for consumer electronics, and achieve the effect of high heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

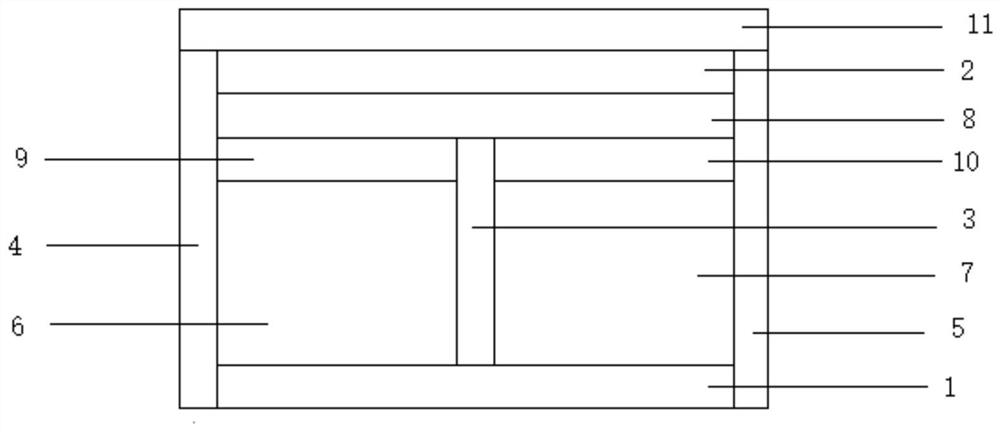

[0029] Embodiment: A film with a heat dissipation structure, including a first heat-insulating and insulating ink layer, a second heat-insulating and insulating ink layer, a third heat-insulating and insulating ink layer, a P-type ink layer, an N-type ink layer, and an upper heat-conducting and insulating silica gel Cloth, lower thermal conductive insulating silicone cloth, first low-temperature silver paste layer, second low-temperature silver paste layer and third low-temperature silver paste layer, the upper surface of the first low-temperature silver paste layer used to connect the positive electrode is fixedly stacked with a P-type ink layer , the surface of the second low-temperature silver paste layer used to connect to the negative electrode is fixedly stacked with an N-type ink layer, the first low-temperature silver paste layer and the P-type ink layer on it form the first inner core, and the second low-temperature silver paste layer And the N-type ink layer on it for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com