Silicon carbide-based DSRD device with p-type variable doping base region and preparation method thereof

A silicon carbide-based, variable doping technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficulty in fully utilizing silicon carbide materials, limiting DSRD device performance, and affecting carrier extraction speed , to achieve the effects of improving device reliability, shortening the pulse front, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

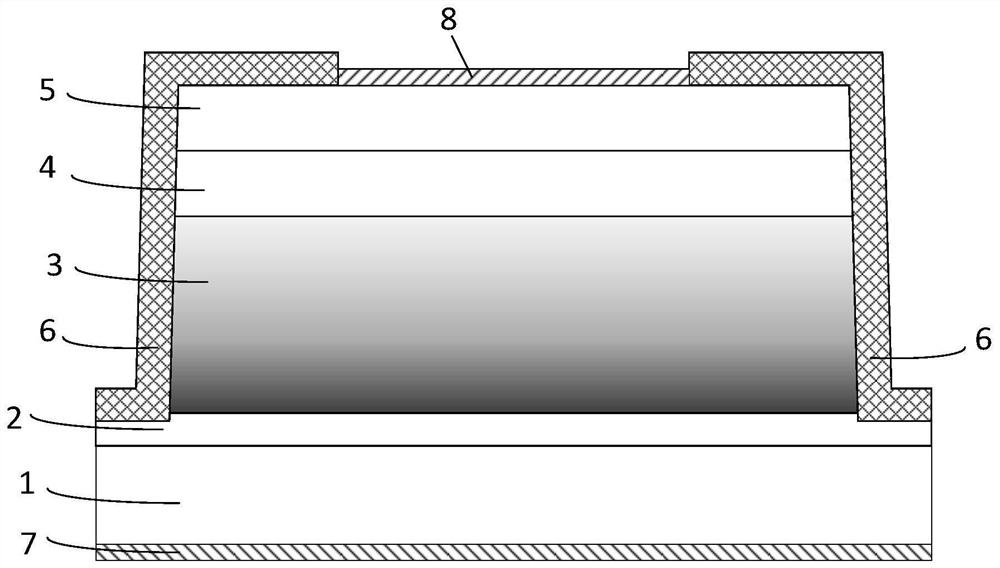

[0043] See figure 1 , figure 1It is a schematic structural diagram of a silicon carbide-based DSRD device with a P-type variable doping base region provided by an embodiment of the present invention. The SiC-based DSRD device includes substrate 1, N+ buffer zone 2, P-base region 3, P+ buffer region 4, P+ region 5, SiO 2 Passivation layer 6, cathode 7 and anode 8. The substrate 1, the N+ buffer area 2, the P-base area 3, the P+ buffer area 4 and the P+ area 5 are arranged sequentially from bottom to top.

[0044] Preferably, the substrate 1 has a thickness of 350 μm and a doping concentration of 5×10 18 cm -3 SiC material.

[0045] Preferably, the N+ buffer zone 2 is an N-type SiC material with a doping concentration of 1×10 18 cm -3 , the dopant ions are nitrogen ions.

[0046] Preferably, the P-base region 3 is a P-type SiC material with a doping concentration of 1×10 15 cm -3 to 2×10 16 cm -3 And increasing from top to bottom, the dopant ions are aluminum ions. ...

Embodiment 2

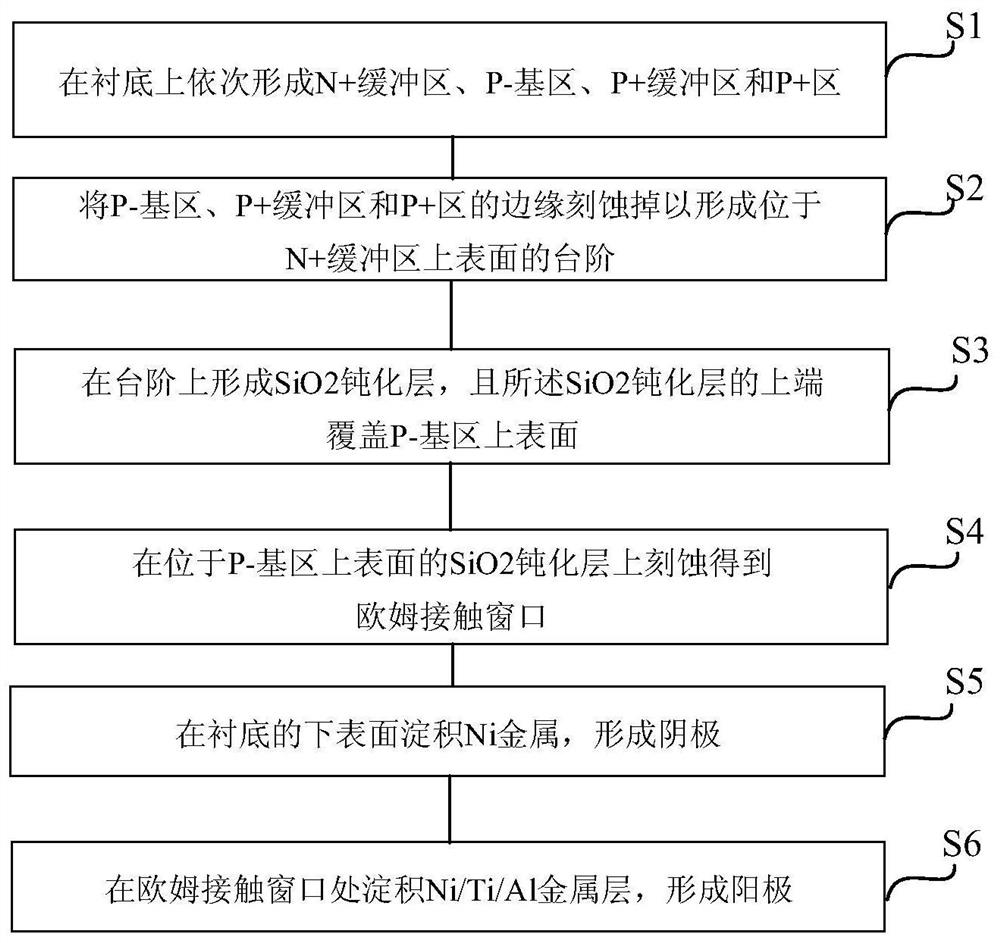

[0056] On the basis of the first embodiment, this embodiment provides a method for preparing a silicon carbide-based DSRD device with a P-type variable doping base region, which is used to prepare the silicon carbide-based DSRD device described in the first embodiment. See figure 2 , figure 2 It is a flowchart of a method for preparing a silicon carbide-based DSRD device with a P-type variable doping base region provided by an embodiment of the present invention. The preparation method includes:

[0057] S1: Form N+ buffer zone, P-base region, P+ buffer zone and P+ region sequentially on the substrate;

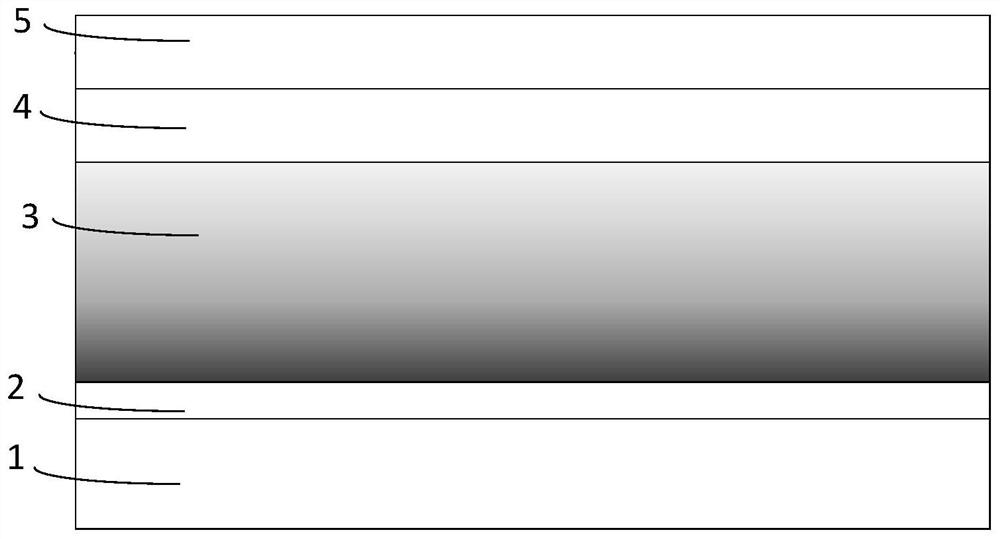

[0058] See Figure 3a to Figure 3f , Figure 3a to Figure 3f It is a schematic diagram of the manufacturing process of a silicon carbide-based DSRD device with a P-type variable doping base region provided by an embodiment of the present invention. Step S1 specifically includes: selecting a thickness of 350 μm and a doping concentration of 5×10 18 cm -3 RCA standard c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com