A kind of preparation method of nitrogen-doped porous carbon electrocatalyst with core-shell structure

A technology of nitrogen-doped porous carbon and core-shell structure, which is applied in structural parts, circuits, electrical components, etc., can solve the problems of unfavorable active centers using substrate transport, high raw material costs, and high active layer thickness to achieve excellent reactivity , low price, and improved electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

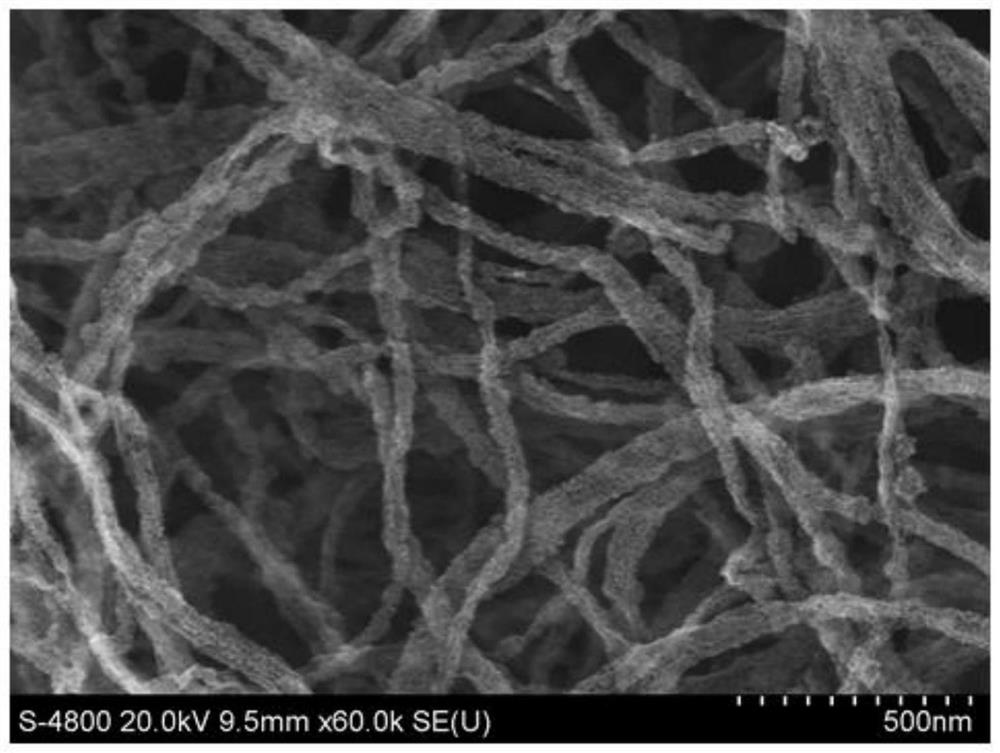

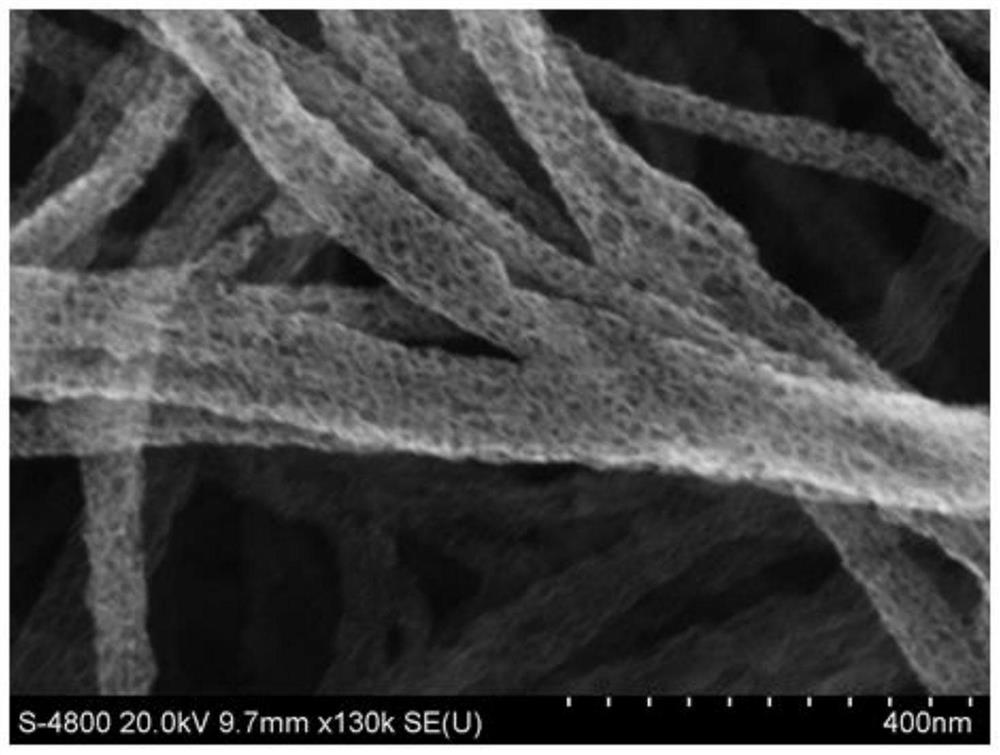

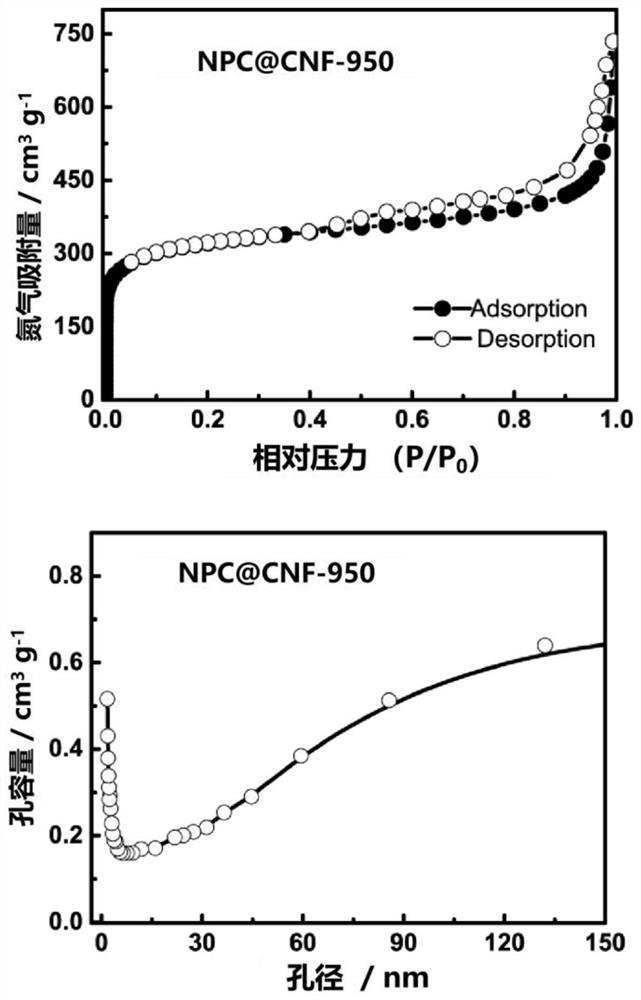

[0034] The BC film was cut into pieces (4.0 cm × 8.0 cm), washed with deionized water and put into 30 mL of 0.2 mol / L Zn(NO 3 ) 2methanol solution, then placed in a 50mL stainless steel autoclave, closed reaction at 100°C for 12 hours, then took it out, rinsed it with distilled water, and freeze-dried. The dried product sheet was immersed in 30mL of 0.1mol / L methanol solution of 2-methylimidazole, and reacted at 80°C for 12h, rinsed with distilled water after taking it out, and freeze-dried to obtain ZIF- 8 is the ZIF-8@BC membrane of the shell. The ZIF-8@BC film was placed in a nitrogen atmosphere at a temperature of 3°C / min to 950°C, graphitized at 950°C for 3 hours in a nitrogen atmosphere, and an NPC@CNF carbon film with high conductivity and high electrocatalytic activity was obtained after annealing and cooling , tagged NPC@CNF-950.

[0035] After testing, the coating thickness of the nitrogen-doped porous carbon of the NPC@CNF-950 product is 30-50nm, and the thicknes...

Embodiment 2

[0037] The BC film was cut into pieces, washed with deionized water and put into 30mL 0.1mol / L Zn(NO 3 ) 2 methanol solution, then placed in a 50mL stainless steel autoclave, closed reaction at 100°C for 12 hours, then took it out, rinsed it with distilled water, and freeze-dried. The dried product sheet was immersed in 30mL of 0.1mol / L methanol solution of 2-methylimidazole, and reacted at 80°C for 6h, rinsed with distilled water after taking it out, and freeze-dried to obtain ZIF- 8 is the ZIF-8@BC membrane of the shell. The ZIF-8@BC film was placed in a nitrogen atmosphere at a temperature of 3°C / min to 950°C, graphitized at 950°C for 3 hours in a nitrogen atmosphere, and an NPC@CNF carbon film with high conductivity and high electrocatalytic activity was obtained after annealing and cooling .

[0038] By adjusting the concentration of zinc salt and the reaction time with 2-methylimidazole, the NPC@CNF carbon film product with nitrogen-doped porous carbon coating thickne...

Embodiment 3

[0040] The BC film was cut into pieces, washed with deionized water and put into 30 mL of 0.5 mol / L Zn(NO 3 ) 2 methanol solution, then placed in a 50mL stainless steel autoclave, closed reaction at 100°C for 12 hours, then took it out, rinsed it with distilled water, and freeze-dried. The dried product sheet was immersed in 30 mL of 0.1 mol / L methanol solution of 2-methylimidazole, and reacted at 80°C for 8 hours, rinsed with distilled water after taking it out, and freeze-dried to obtain ZIF- 8 is the ZIF-8@BC membrane of the shell. The ZIF-8@BC film was placed in a nitrogen atmosphere at a rate of 6°C / min to 1100°C, graphitized at 1100°C for 6 hours in a nitrogen atmosphere, and an NPC@CNF carbon film with high conductivity and high electrocatalytic activity was obtained after annealing and cooling , labeled NPC@CNF-1100.

[0041] By adjusting the concentration of zinc salt and the reaction time with 2-methylimidazole, the NPC@CNF-1100 carbon film product with a coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com