Lignin-based slow-release nitrogen fertilizer as well as preparation method and application thereof

A lignin-based, lignin-based technology is applied in the field of lignin-based slow-release nitrogen fertilizer and its preparation, can solve the problems of use, low nitrogen content, and cannot be used as slow-release nitrogen fertilizer, etc., and achieves high nitrogen grafting rate, organic nitrogen The effect of high content and improving utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

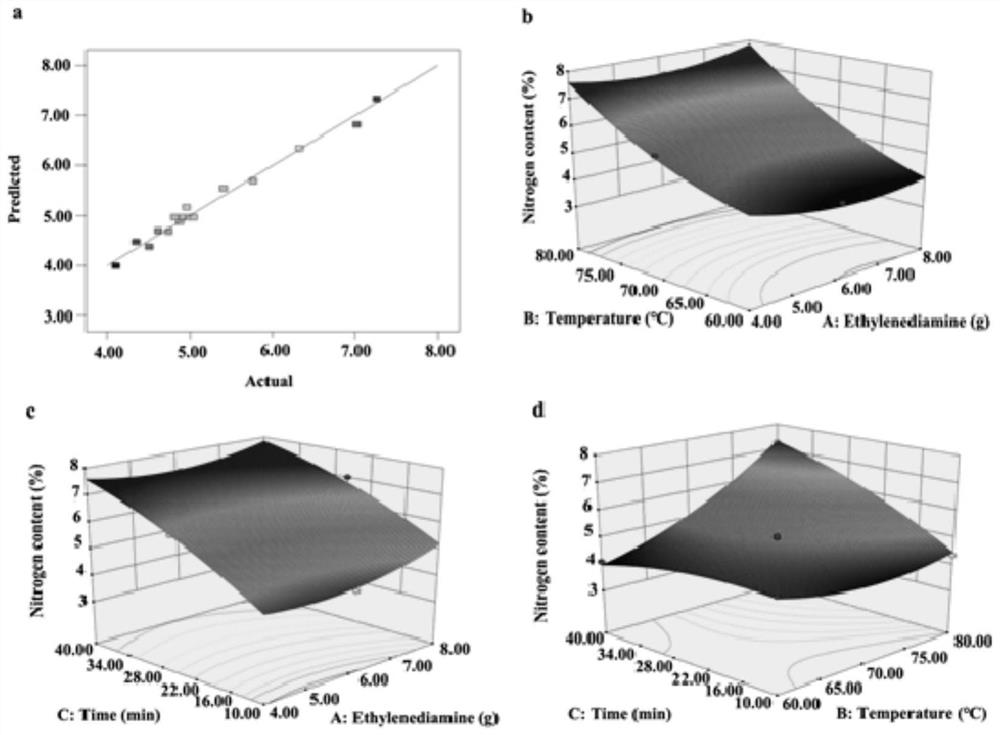

[0060] This embodiment provides a method for preparing lignin-based slow-release nitrogen fertilizer by microwave heating, and its specific steps are:

[0061] Under continuous stirring, firstly, fully dissolve 2 g of phenolized lignin in 40 mL of 1 mol / L sodium hydroxide solution. Next, 6 g of ethylenediamine and 8 g of formaldehyde solution were sequentially added to the above solution. Finally, the above mixed solution was placed in a microwave reactor, and the microwave power was adjusted to 400W, and reacted at 70° C. for 25 minutes. After the reaction, a lignin-based slow-release nitrogen fertilizer was obtained.

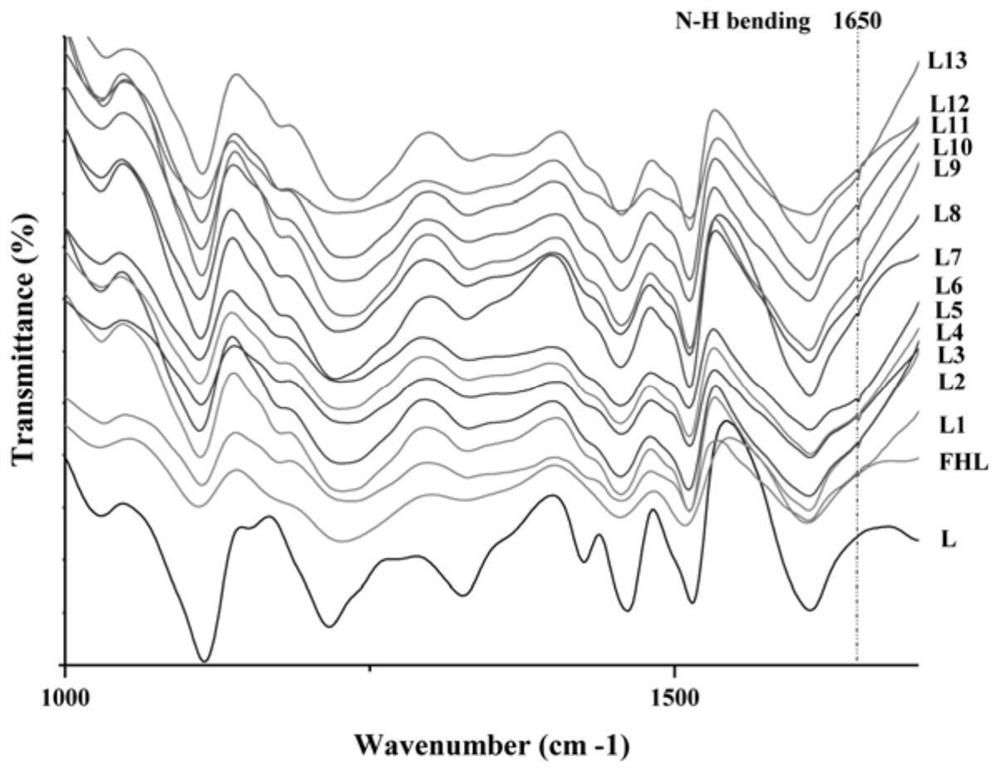

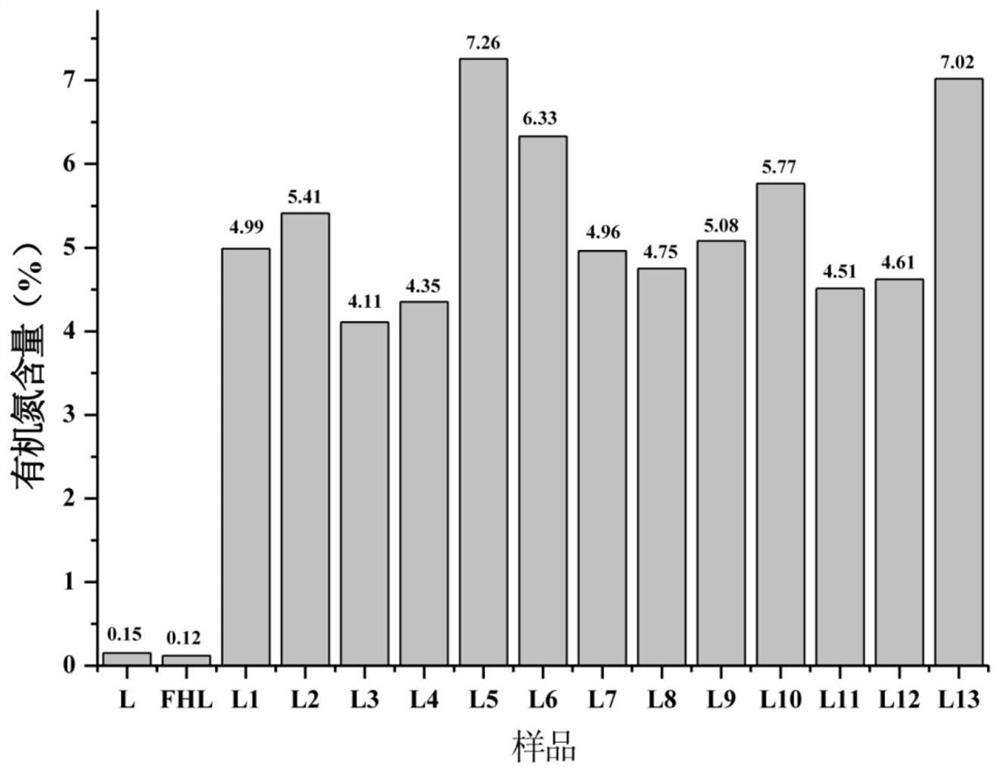

[0062] The infrared spectrum of the lignin-based slow-release nitrogen fertilizer prepared in this embodiment is as follows: figure 1 As shown in (L1), the organic nitrogen content is as figure 2 (L1) shown. It can be seen from the figure that N is effectively incorporated into the molecular structure of the prepared lignin-based slow-release nitrogen fert...

Embodiment 2

[0064] This embodiment provides a method for preparing lignin-based slow-release nitrogen fertilizer by microwave heating, and its specific steps are:

[0065] Under continuous stirring, firstly, fully dissolve 2 g of phenolized lignin in 40 mL of 1 mol / L sodium hydroxide solution. Next, 8 g of ethylenediamine and 8 g of formaldehyde solution were sequentially added to the above solution. Finally, the above mixed solution was placed in a microwave reactor, and the microwave power was adjusted to 400W, and reacted at 70° C. for 40 minutes. After the reaction, a lignin-based slow-release nitrogen fertilizer was obtained.

[0066] The infrared spectrum of the lignin-based slow-release nitrogen fertilizer prepared in this embodiment is as follows: figure 1 As shown in (L2), the organic nitrogen content is as figure 2 (L2) shown. It can be seen from the figure that N is effectively inserted into the molecular structure of the prepared lignin-based slow-release nitrogen fertiliz...

Embodiment 3

[0068] This embodiment provides a method for preparing lignin-based slow-release nitrogen fertilizer by microwave heating, and its specific steps are:

[0069] Under continuous stirring, firstly, fully dissolve 2 g of phenolized lignin in 40 mL of 1 mol / L sodium hydroxide solution. Next, 6 g of ethylenediamine and 8 g of formaldehyde solution were sequentially added to the above solution. Finally, the above mixed solution was placed in a microwave reactor, and the microwave power was adjusted to 400W, and reacted at 60° C. for 40 minutes. After the reaction, a lignin-based slow-release nitrogen fertilizer was obtained.

[0070] The infrared spectrum of the lignin-based slow-release nitrogen fertilizer prepared in this embodiment is as follows: figure 1 As shown in (L3), the organic nitrogen content is as figure 2 (L3) shown. It can be seen from the figure that N is effectively inserted into the molecular structure of the prepared lignin-based slow-release nitrogen fertiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com