Alkaline compound liquid fertilizer containing lignin-based long-acting nitrogen fertilizer, preparation method and application thereof

A compound liquid, lignin-based technology, applied in the field of fertilizers, can solve the problems of inability to directly use as slow-release nitrogen fertilizer, poor soil pH, low nitrogen content, etc., achieve excellent uniformity and stability, improve utilization value, The effect of high fertilizer utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A preparation method of an alkaline compound liquid fertilizer containing lignin-based long-acting nitrogen fertilizer, the steps of which are:

[0068] Under continuous stirring, firstly, 5 g of phenolized lignin was fully dissolved in 10 mL of 0.4 mol / L potassium hydroxide solution. Next, 15g of ethylenediamine and 20g of formaldehyde solution were sequentially added to the above solution. Finally, the above mixture was placed in a microwave reactor (400W, the same below) to react at 80° C. for 40 minutes, and a solution containing lignin long-acting nitrogen fertilizer was obtained after the reaction was completed.

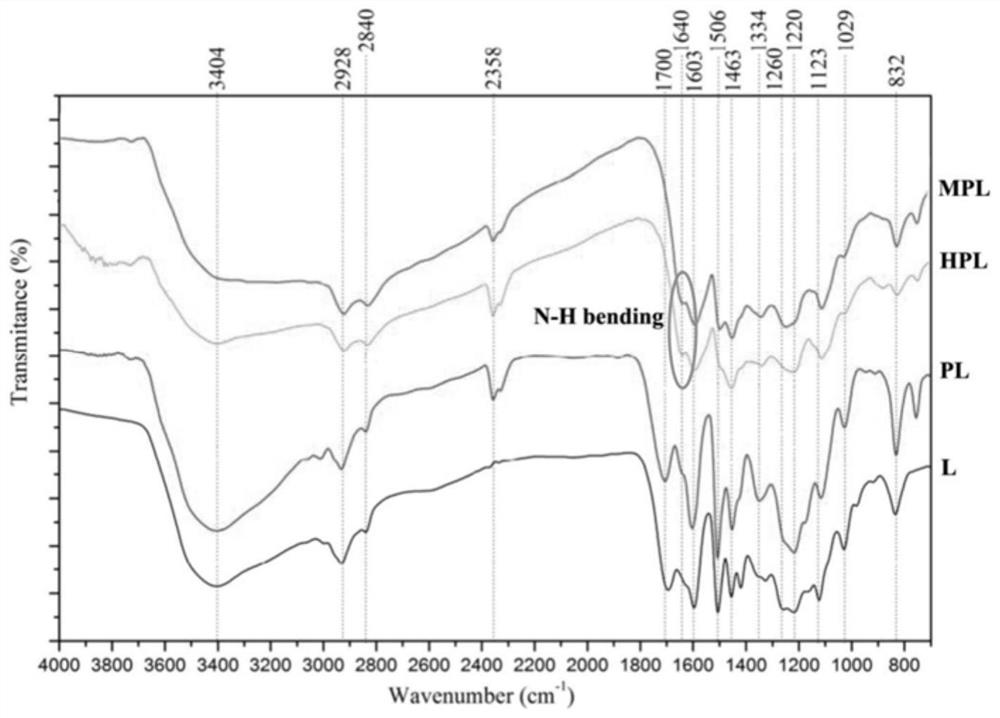

[0069] Such as figure 1 , is the infrared spectrogram (MPL) of the lignin long-acting nitrogen fertilizer. It can be seen from the figure that N is effectively inserted into the prepared lignin long-acting nitrogen fertilizer. The mass concentration of lignin in the solution is 29g / L, and the content of organic nitrogen in the lignin is 7.2%.

[0070]...

Embodiment 2

[0073] A preparation method of an alkaline compound liquid fertilizer containing lignin-based long-acting nitrogen fertilizer, the steps of which are:

[0074] Under continuous stirring, firstly, 5 g of phenolized lignin was fully dissolved in 10 mL of 0.4 mol / L potassium hydroxide solution. Next, 20 g of ethylenediamine and 20 g of formaldehyde solution were sequentially added to the above solution. Finally, the above mixture was placed in a microwave reactor to react at 80° C. for 25 minutes, and a solution containing lignin long-acting nitrogen fertilizer was obtained after the reaction.

[0075] The lignin mass concentration of the solution is 28g / L, and the content of organic nitrogen in the lignin is 7.0%.

[0076] Take 800 mL of the above solution, add 50.7 g of potassium nitrate, 230 g of potassium dihydrogen phosphate and 4.4 g of potassium chloride, and then dilute the solution to 1 L with distilled water. Finally, adjust the pH of the solution to be 7.5, namely th...

Embodiment 3

[0079] A preparation method of an alkaline compound liquid fertilizer containing lignin-based long-acting nitrogen fertilizer, the steps of which are:

[0080] Under continuous stirring, firstly, 5 g of phenolized lignin was fully dissolved in 10 mL of 0.4 mol / L potassium hydroxide solution. Next, 10 g of ethylenediamine and 20 g of formaldehyde solution were sequentially added to the above solution. Finally, the above mixture was placed in a microwave reactor to react at 80° C. for 25 minutes, and a solution containing lignin long-acting nitrogen fertilizer was obtained after the reaction.

[0081] The mass concentration of lignin in the solution is 25g / L, and the content of organic nitrogen in the lignin is 6.3%.

[0082] Take 800 mL of the above solution, add 72.5 g of potassium nitrate and 230 g of potassium dihydrogen phosphate, and then dilute the solution to 1 L with distilled water. Finally, adjust the pH of the solution to be 7.5, i.e. the alkaline compound liquid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com