Scanning type air leakage monitoring device and mounting method thereof

A monitoring device, scanning technology, applied in the direction of furnace monitoring device, furnace type, furnace, etc., can solve the problems of real-time monitoring, complicated measurement methods, and complicated installation of monitoring devices, so as to achieve simple and convenient installation, avoid investment and Large-scale transformation, the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

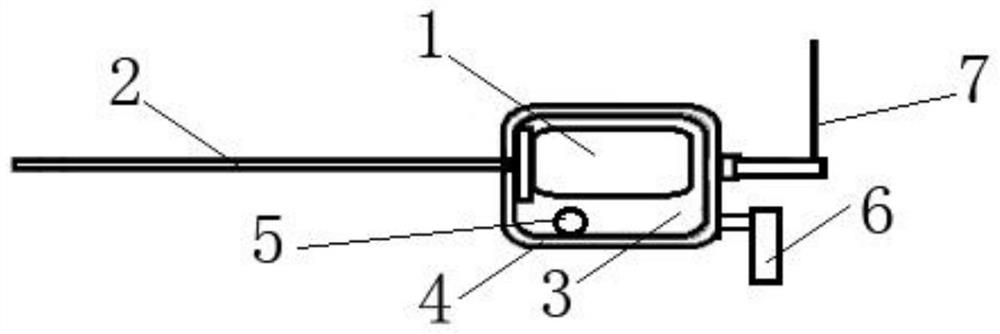

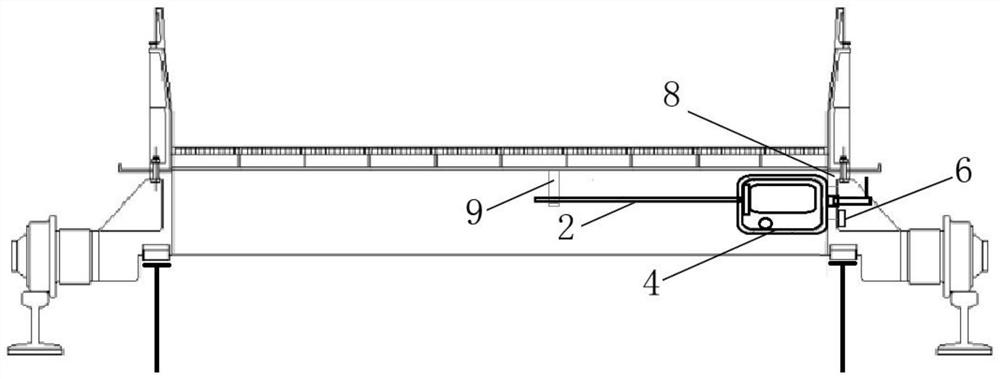

[0026] Such as figure 1 As shown, a scanning air leakage monitoring device includes a monitor 1, a cooler 3, and a data transmitter 7; the monitor 1 is internally provided with an oxygen analyzer measuring instrument, and one end of the monitor 1 is connected to a monitoring probe 2 , the other end is connected with a data transmitter 7; the cooler 3 is arranged on the periphery of the monitor 1, and the cooler 3 is composed of a high temperature resistant protective shell 4, a cold air valve 5 and a cooling fin 6; the cold air valve 5 is located at The inner side of the high temperature resistant protective shell 4; the externally connected heat sink 6 of the high temperature resistant protective shell 4;

[0027] The high temperature resistant protective shell 4 is lined with a heat resistant composite material;

[0028] The heat sink 6 is in a normal temperature state, and conducts the heat of the high temperature resistant protective shell 4 to the outside of the trolley;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com