Active driving circuit and method of MOSFET

A technology of source driving and driving resistance, which is applied in the field of power electronics, can solve the problems of poor suppression effect, large switching loss, and long switching time, and achieve the effects of reducing switching loss and cost, suppressing current overshoot, and shortening switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

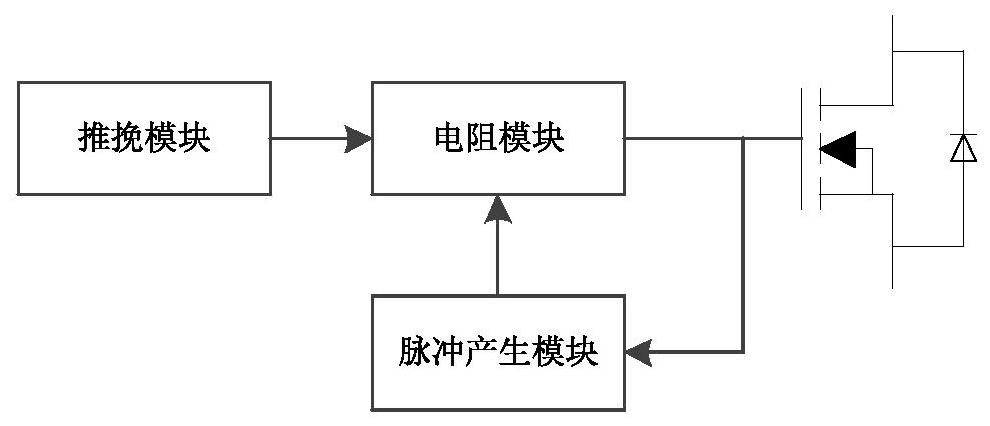

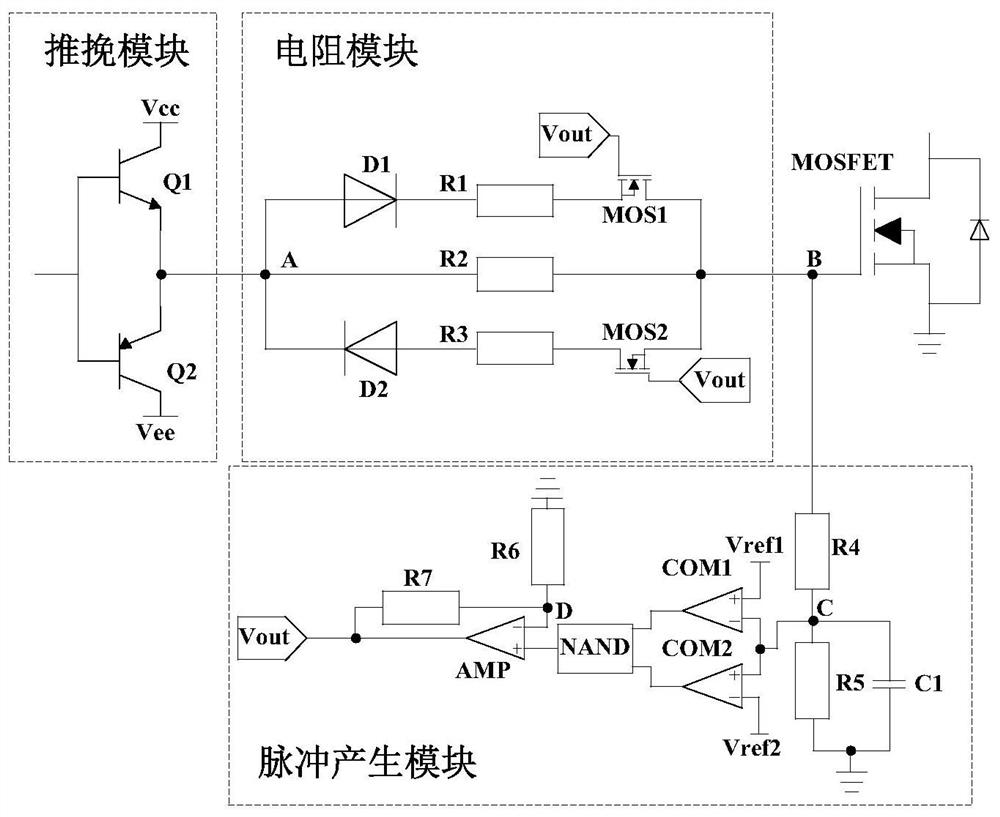

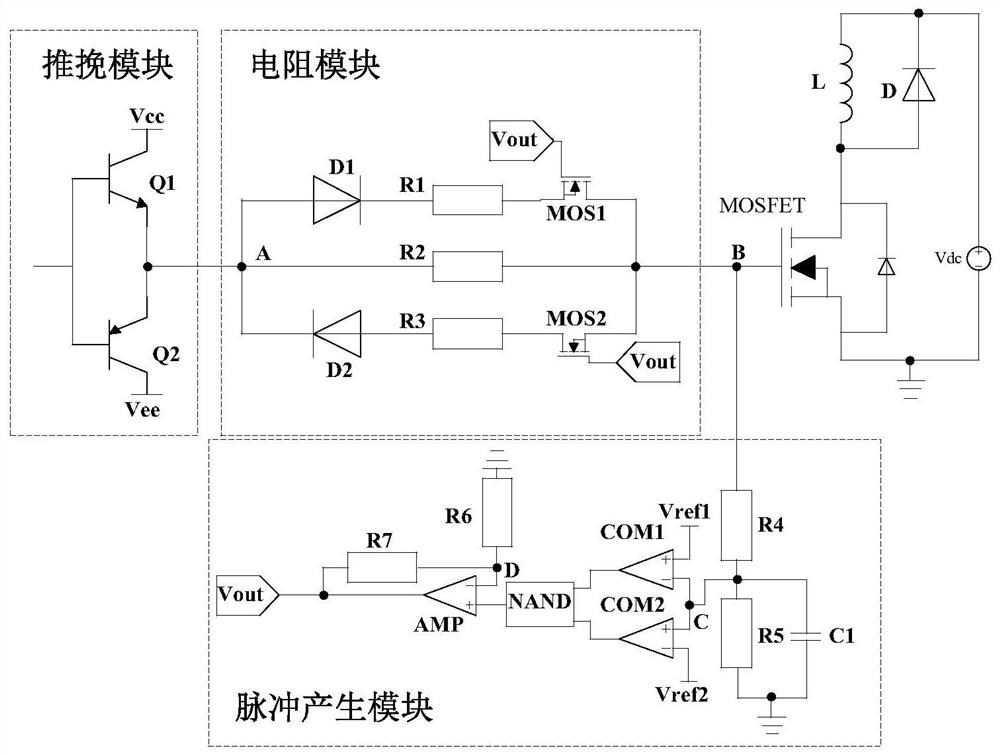

[0051] Embodiment 1 of the present invention provides an active drive circuit for MOSFET, such as figure 1 As shown, including push-pull module, resistance module and pulse generation module;

[0052] The push-pull module is connected to the gate of the driven MOSFET through the resistance module, one end of the pulse generating module is connected to the gate of the driven MOSFET, and the other end is connected to the resistance module;

[0053] Based on the driving voltage of the driven MOSFET generated by the push-pull module and the pulse signal generated by the pulse generating module based on the collected gate-source voltage of the driven MOSFET, a variable driving resistance is provided for the driven MOSFET.

[0054] The pulse generating module includes a sampling circuit, a pulse generating circuit and an amplifying circuit;

[0055] One end of the sampling circuit is connected to the gate of the driven MOSFET, and the other end is connected to the input end of the ...

Embodiment 2

[0072] Embodiment 2 of the present invention provides an active driving method for MOSFET, such as Image 6 shown, including:

[0073] S101: the push-pull module generates the driving voltage of the driven MOSFET;

[0074] S102: the pulse generating module collects the gate-source voltage of the driven MOSFET, and generates a pulse signal based on the gate-source voltage;

[0075] S103: the resistance module provides variable driving resistance for the driven MOSFET based on the driving voltage and the pulse signal.

[0076] In the above S103, the resistance module provides a variable driving resistance for the driven MOSFET based on the driving voltage and the pulse signal, which is specifically divided into two cases: MOSFET turn-on process and turn-off process.

[0077] During the MOSFET turn-on process, the resistance module provides variable driving resistance for the driven MOSFET based on the driving voltage and pulse signal, including:

[0078] The sampling circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com