Tunnel furnace

A tunnel furnace and pipeline technology, applied in food ovens, oven air treatment devices, food processing, etc., can solve the problems of poor heating effect, inability to adjust the height of the mesh belt above the conveying chain plate, and inability to adapt to higher heights Product drying effect and other issues to achieve the effect of improving the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

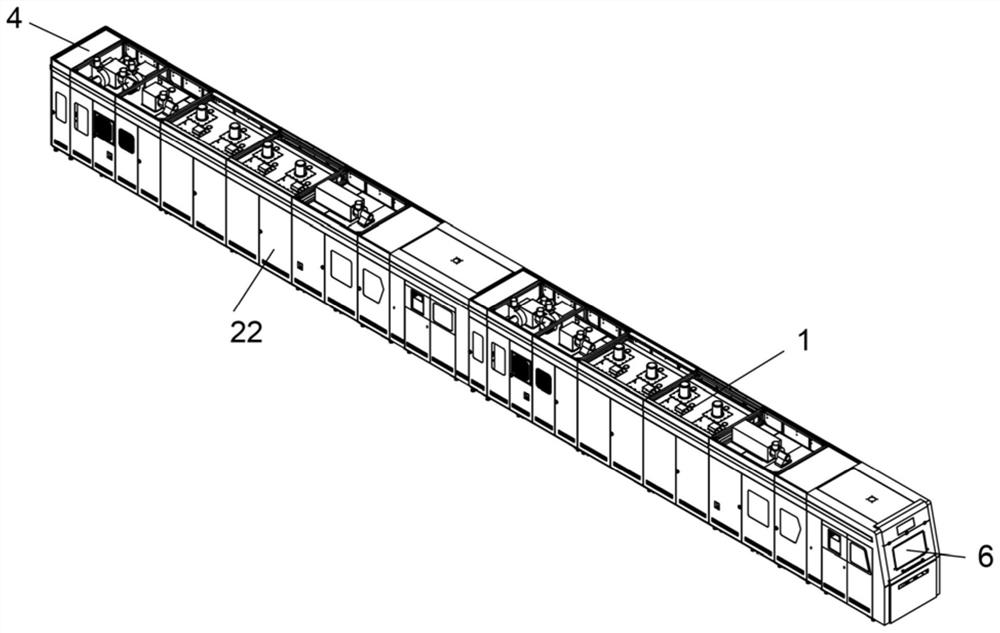

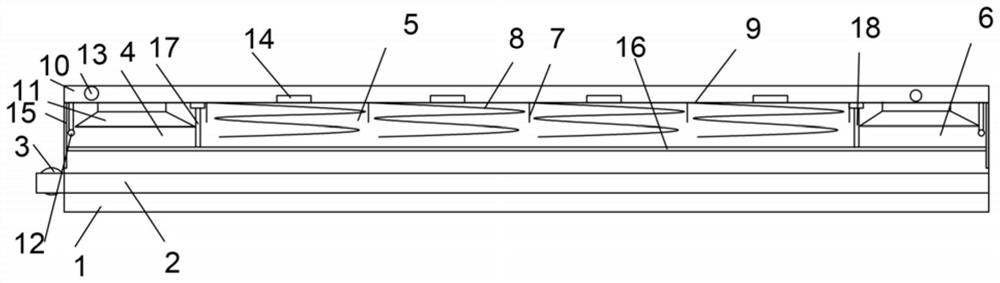

[0030] see Figure 1-Figure 2 , the present embodiment provides a tunnel furnace, including a tunnel furnace body 1, a conveying pipeline 2 for placing products is provided in the tunnel furnace body 1, the side of the conveying pipeline 2 is driven by a first motor 3, and the tunnel furnace The furnace body 1 includes a feed area 4, a heating area 5, and a discharge area 6. The heating area 5 includes more than one heating box 7 arranged from left to right, and a spiral heating wire is arranged inside the heating box 7. 8. A first partition 9 is provided above the tunnel furnace body 1 to isolate the tunnel furnace body 1 from top to bottom. The upper chamber of the tunnel furnace body 1 is used as a waste heat absorption pipe 10, and is connected between the feed area 4 and the outlet An air outlet channel 11 and a high-pressure blower 12 are provided in the material area 6, and an aspirator 13 connected to the corresponding air outlet channel 11 is respectively provided on ...

Embodiment 2

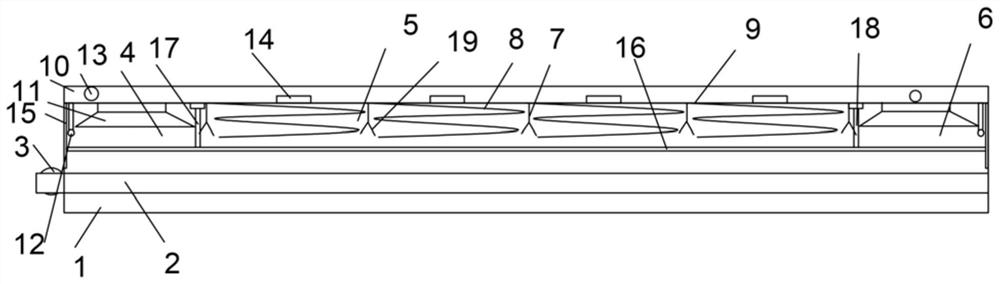

[0034] see image 3 , present embodiment provides a kind of tunnel furnace, further, increase the temperature of heat, further improve heating effect, be provided with the heating plate 19 that obliquely arranges on the both sides of heating box 7, by setting heating plate 19, utilize heating plate 19 to make The generated heat is heated up twice to improve the heating effect on the product.

Embodiment 3

[0036] see Figure 4 , present embodiment provides a kind of tunnel furnace, in order to display conveniently, on the left side of tunnel furnace body 1, be provided with controller 20 and liquid crystal display 21 that control whole equipment work, display internal temperature or data information through liquid crystal display 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com