A kind of gutta-percha containing boron nitride and preparation method thereof

A boron nitride and gutta-percha technology, which is used in dental preparations, dentistry, pharmaceutical formulations, etc., can solve the problems that the flow performance is difficult to become a filling effect gutta-percha material, and the fluidity of the material is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

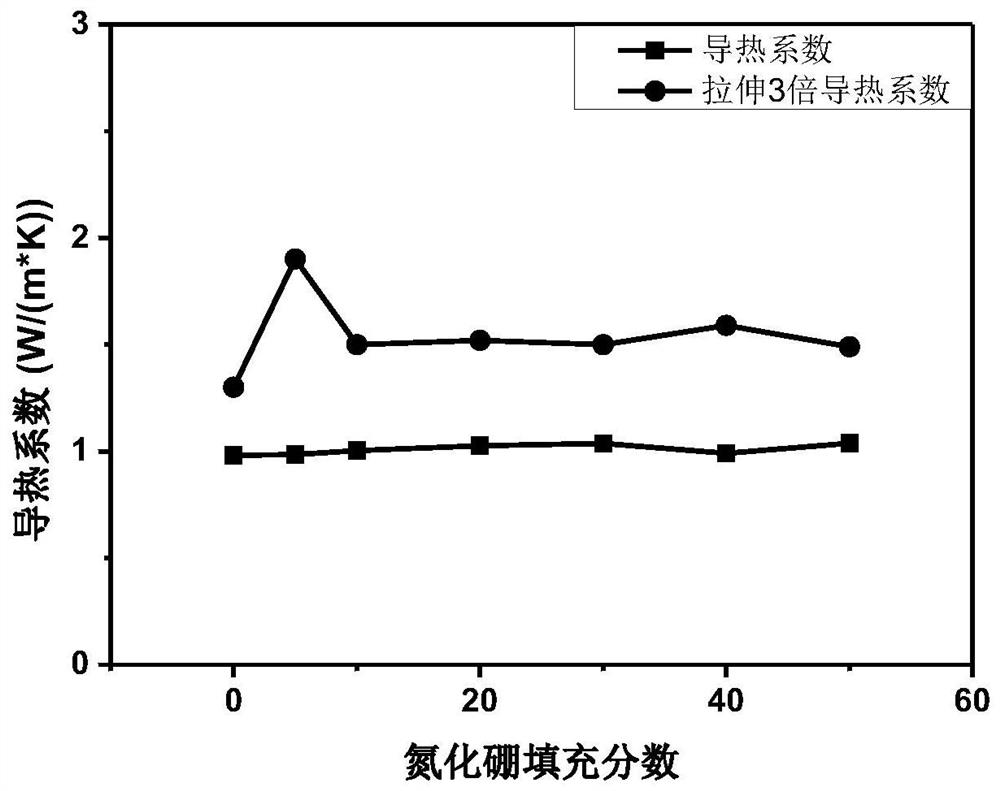

Embodiment 1

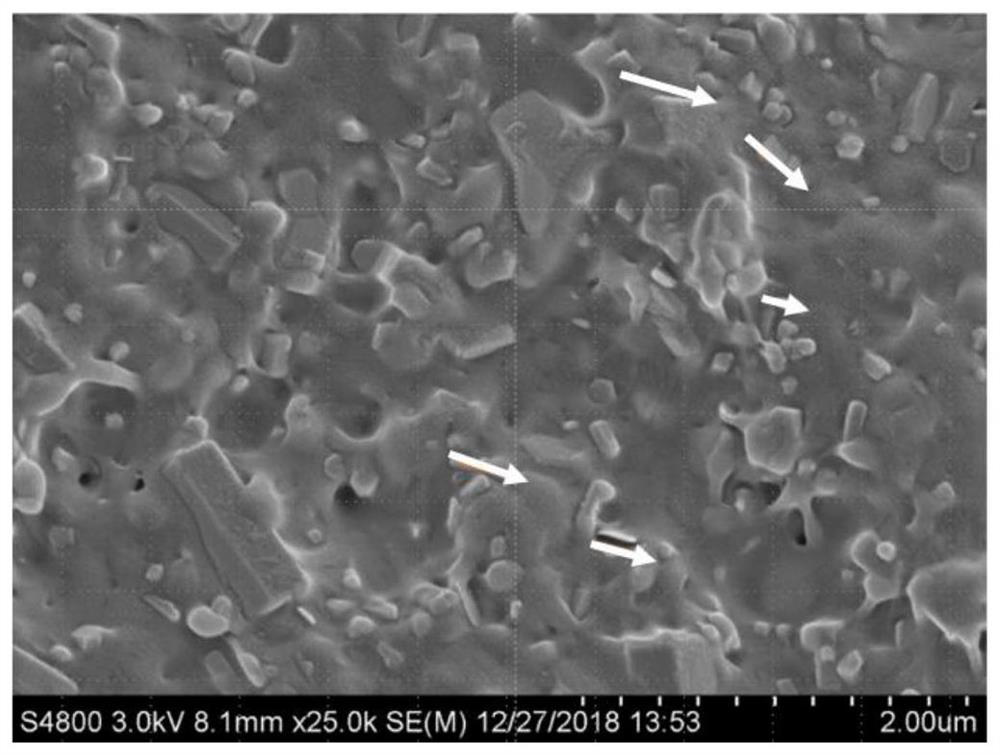

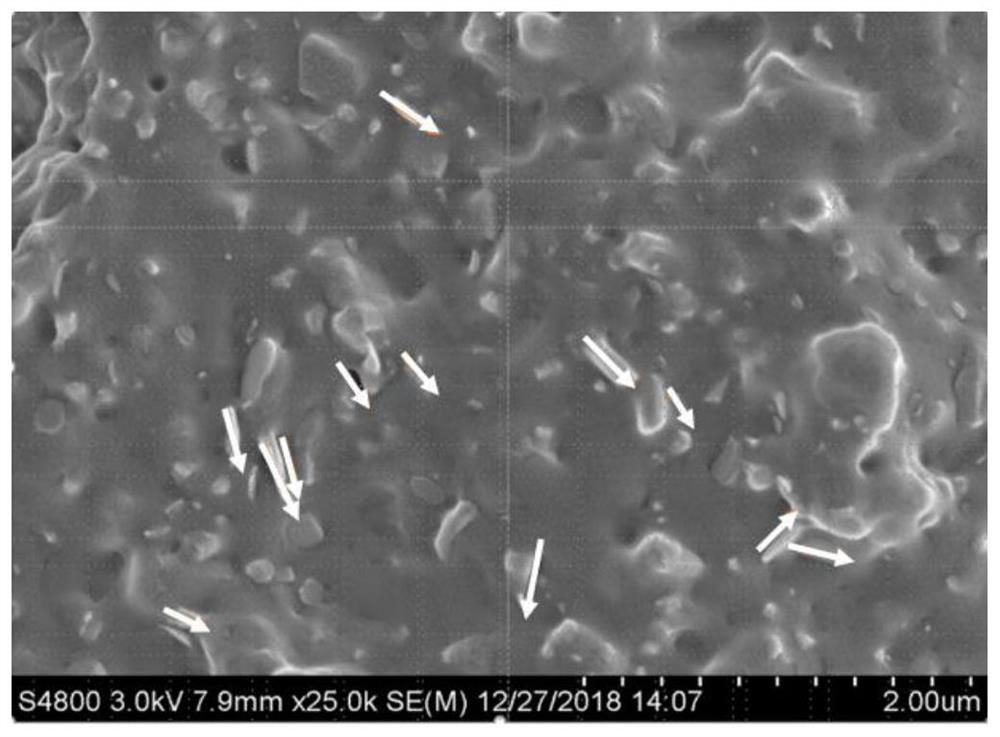

[0037] The temperature of the hot roller was set at 65°C, 100 parts by mass of eucommia gum, 250 parts by mass of zinc oxide, and 1 part by mass of boron nitride (the thickness of boron nitride is about 65 nm, and the surface size is 200 nm-1 μm.). Put the uniformly kneaded sample into a 25t flat-plate vulcanizer for tablet pressing, and after cutting, put it into a high-temperature stretching oven for stretching orientation. The test temperature is 70 degrees Celsius, the stretching rate is 500 mm / min, and the thermal conductivity in the thermal conductivity direction is tested. . In addition, the mixed material was tested with a melt index meter for flow properties. The specific operation steps were as follows: cut the sample into small pieces and place them in the melt index meter for 300S and then extrude. The extrusion temperature was 120°C and the pressure was 2Kg. The composite material of 100 parts by mass of eucommia gum and 250 parts by mass of zinc oxide was set as ...

Embodiment 2

[0039] The temperature of the hot roller was set at 65° C., 100 parts by mass of eucommia glue, 400 parts by mass of zinc oxide, and 5 parts by mass of boron nitride (the thickness of boron nitride is about 65 nm, and the surface size is 200 nm-1 μm). The thermal conductivity of the composite material in the orientation direction is tested. First, the composite material is placed in a 25t flat vulcanizer for pressing and cutting, and then placed in a high-temperature stretching oven for stretching orientation. The test temperature is 70 degrees Celsius and the stretching rate is 500 mm / min. And test the thermal conductivity in the direction of heat conduction. The composites were tested for flow in a melt indexer. Extruded after being kept for 300S in a melt index meter, and the extrusion temperature was 120°C. The composite material of 100 parts by mass of eucommia gum and 400 parts by mass of zinc oxide was set as the matrix composite material, and its MFR (g / 10min) was set...

Embodiment 3

[0041] The temperature of the hot roller was set at 65° C., 100 parts by mass of eucommia glue, 400 parts by mass of zinc oxide, and 10 parts by mass of boron nitride (the thickness of boron nitride is about 65 nm, and the surface size is 200 nm-1 μm). The thermal conductivity measurement process of the composite material after orientation is firstly to put the composite material in a 25t flat vulcanizer for pressing and cutting, and then put it into a high-temperature stretching oven for stretching orientation. The test temperature is 70 degrees Celsius and the stretching rate is 500 mm. / min and test the thermal conductivity in the direction of heat conduction. The fluidity of the composite material was tested in a capillary rheometer, and then extruded after being held in a capillary rheometer for 300 s. The extrusion temperature was 120 °C and the shear rate was set at 300 s. -1. The composite material of 100 parts by mass of eucommia gum and 400 parts by mass of zinc oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com