Normal-pressure continuous quantitative feeding system for alkylating device active agent

A technology of quantitative feeding and active agent, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of extending the service life of equipment, stabilizing device operation, and solving dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

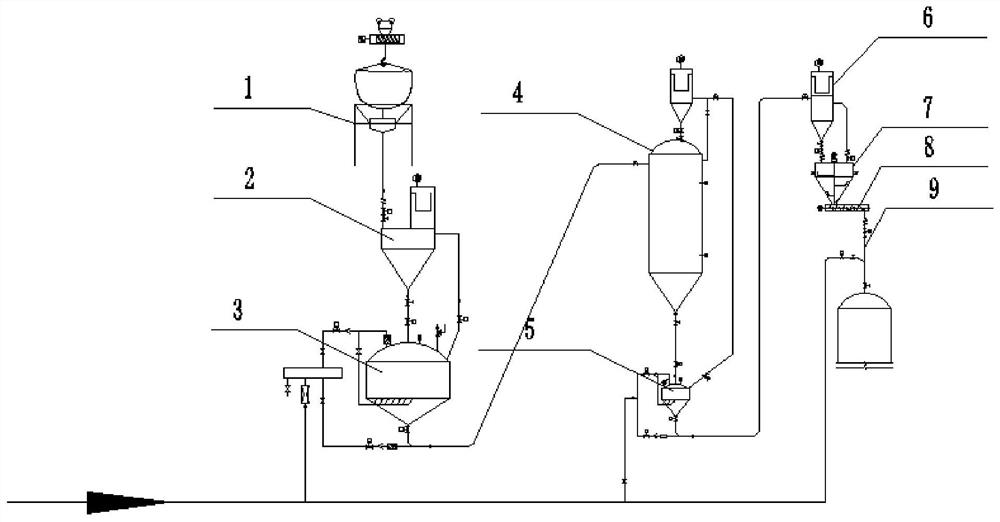

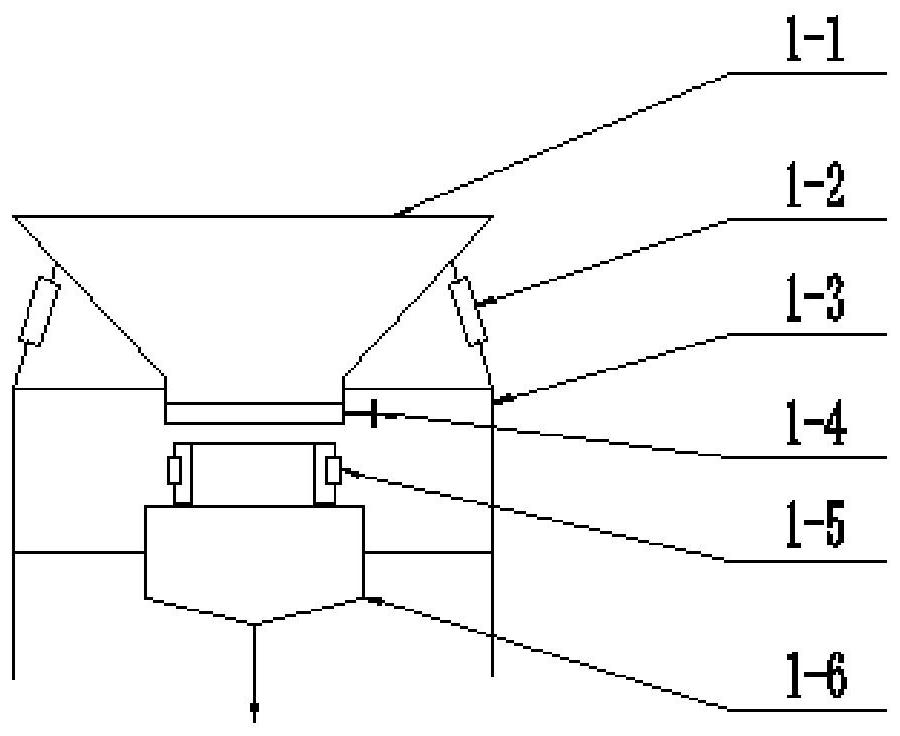

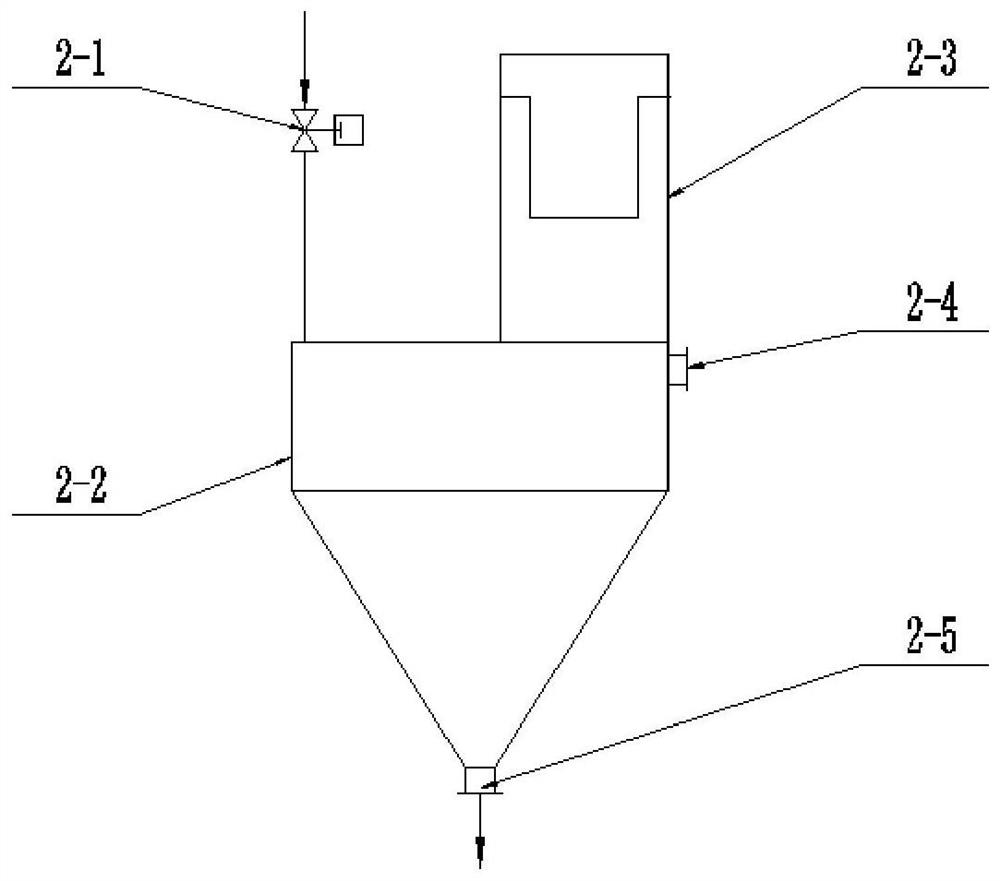

[0076] Such as figure 1 As shown, Example 1 of the present invention is a schematic structural diagram of an atmospheric continuous quantitative feeding system for an active agent in an alkylation unit, wherein 1 is an airtight unloader, 2 is an active agent buffer and micro-negative pressure dust removal unit, and 3 4 is active agent storage and filtration unit, 5 is small automatic feeding metering and conveying equipment, 6 is temporary storage and dust removal unit, 7 is weighing metering and anti-adhesion unit, 8 is double-helix continuous The dosing unit, 9 is an emergency shutdown cut-off unit; the normal pressure continuous dosing system for the active agent in the alkylation unit of the present invention includes: a closed unloader 1, an active agent buffer and micro-negative pressure dust removal unit 2, Closed dense-phase conveying equipment 3, active agent storage and filtration unit 4, small automatic feeding metering and conveying equipment 5, temporary storage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com