Normal-pressure preparation method of rare-earth oxide doped cerium oxide aerogel

A rare earth oxide, cerium oxide technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc. problems such as glue shrinkage, to achieve the effects of easy filtration and recovery, high specific surface area, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

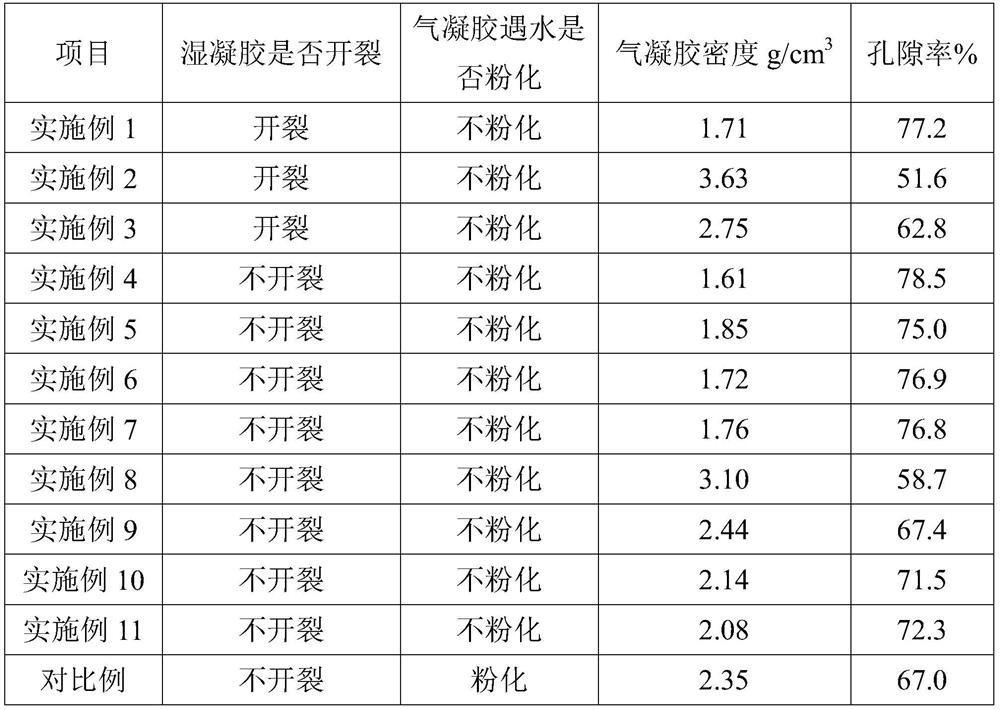

Embodiment 1

[0033] Weigh 2.98g of cerous chloride heptahydrate and add it to 14mL ethanol solution, stir at 700r / min until it dissolves completely, then add 0.513g of samarium chloride and stir until completely dissolved to obtain the alcoholic solution of the metal salt; 11 mL of propylene oxide was added dropwise into the solution, and stirred at 1000 r / min for 5 min after the drop was completed, then the reactor was sealed and allowed to stand at room temperature to obtain a wet gel. In order to maintain the wet state of the wet gel, a small amount of ethanol is added to the wet gel, and it is sealed and aged at room temperature for 24 hours. After that, the wet gel is immersed in the ethanol solution according to the solid-to-liquid volume ratio of 1:1, and the solvent is carried out at room temperature. Replacement, repeated three times. Finally, the wet gel after solvent replacement is dried under normal pressure in the range of 20-200° C. to obtain airgel particles.

Embodiment 2

[0035] Weigh 0.24g of cerous chloride heptahydrate and add it to 14mL ethanol solution, stir at 700r / min until it dissolves completely, then add 0.15g of samarium chloride and stir until completely dissolved to obtain the alcoholic solution of the metal salt; 11 mL of propylene oxide was added dropwise into the solution, and stirred at 1000 r / min for 5 min after the drop was completed, then the reactor was sealed and allowed to stand at room temperature to obtain a wet gel. In order to maintain the wet state of the wet gel, a small amount of ethanol is added to the wet gel, and it is sealed and aged at room temperature for 24 hours. After that, the wet gel is immersed in the ethanol solution according to the solid-to-liquid volume ratio of 1:0.5, and the solvent is carried out at room temperature. Replacement, repeated 4 times. Finally, the wet gel after solvent replacement is dried under normal pressure in the range of 20-200° C. to obtain airgel particles.

Embodiment 3

[0037] Take by weighing 5.6g cerous chloride heptahydrate and join in 14mL ethanol solution, stir until dissolving completely with 700r / min, then add 0.64g samarium chloride and stir until completely dissolving to obtain the alcoholic solution of metal salt; Add 11 mL of propylene oxide dropwise to the solution, and stir at 1000 r / min for 5 min after the dropping, then seal the reactor and let it stand at room temperature to obtain a wet gel, then seal the reactor and stand at room temperature to obtain a wet gel. In order to maintain the wet state of the wet gel, add a small amount of ethanol to the wet gel, and seal it at room temperature for 24 hours to age, then soak the wet gel in the ethanol solution according to the solid-to-liquid volume ratio of 1:2, and carry out the solvent at room temperature Replacement, repeat 2 times. Finally, the wet gel after solvent replacement is dried under normal pressure in the range of 20-200° C. to obtain airgel particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com