Photocuring 3D printed vinyl star-shaped polyphosphate composite photosensitive resin as well as preparation method and application of photocuring 3D printing vinyl star-shaped polyphosphate composite photosensitive resin

A technology of polyphosphate and vinyl printing, applied in the direction of additive processing, etc., can solve the problems of product deformation, non-degradable, and expensive photosensitive resin, and achieve shortened curing time, high mechanical strength, and good photocured crosslinking properties Effect

Pending Publication Date: 2020-12-11

WUHAN INSTITUTE OF TECHNOLOGY

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

SLA technology has the advantages of high precision, good surface quality, stable performance, and high mechanical strength of the product. Its disadvantage is that the molded product needs to be cleaned to remove impurities, which may cause product deformation, and the photosensitive resin is expensive and generally cannot be degraded.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0041] The formula of photocuring 3D printing vinyl star polyphosphate composite photosensitive resin (1000 grams) is as follows:

[0042]

Embodiment 2

[0044] The formula of photocuring 3D printing vinyl star polyphosphate composite photosensitive resin (500 grams) is as follows:

[0045]

[0046]

Embodiment 3

[0048] The formula of photocuring 3D printing vinyl star polyphosphate composite photosensitive resin (200 grams) is as follows:

[0049]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

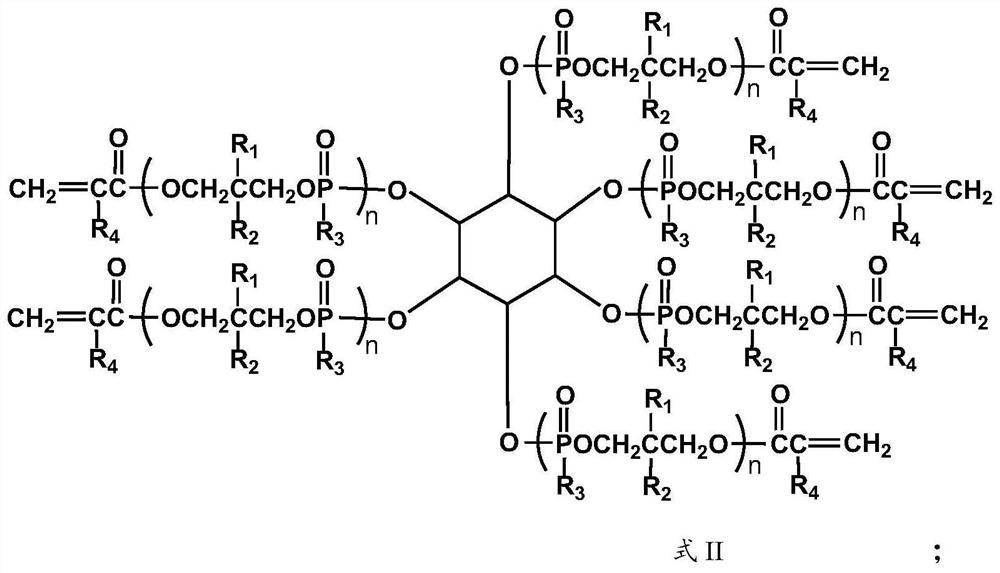

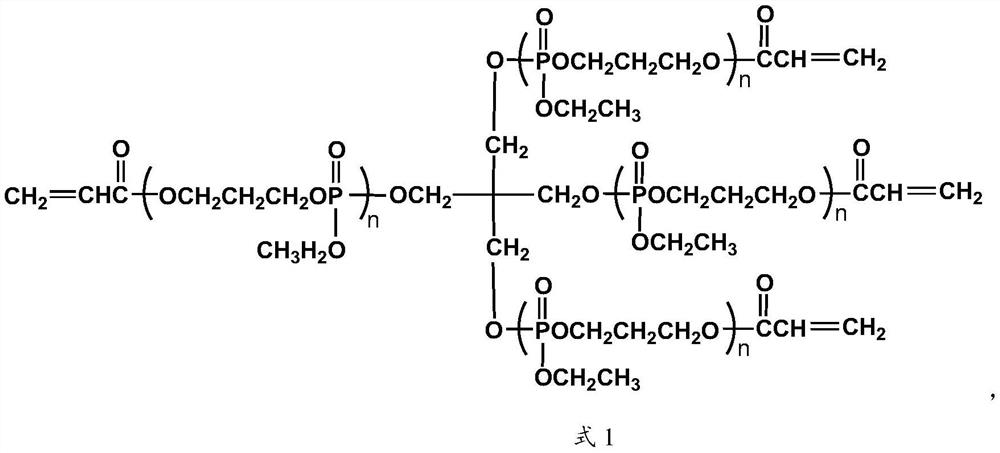

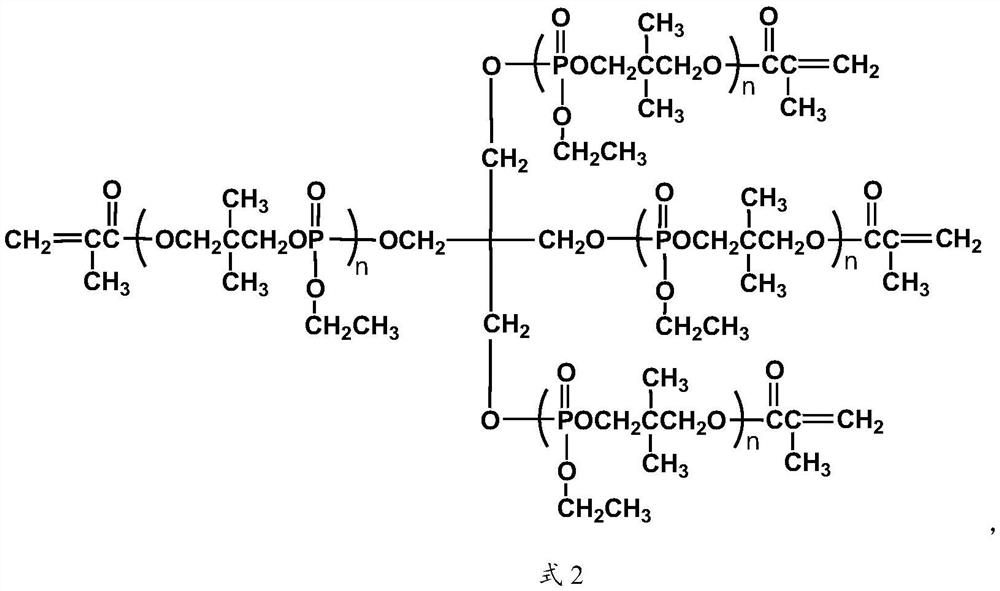

The invention belongs to the technical field of high polymer materials, and particularly relates to photocuring 3D printed vinyl star-shaped polyphosphate composite photosensitive resin as well as a preparation method and application thereof. The material comprises the following components in percentage by weight: 40%-70% of a vinyl star-shaped polyphosphate high polymer material, 5%-60% of a cross-linking agent, 5%-25% of a photoinitiator, 5%-40% of a diluent, 0%-25% of a solvent and 0%-30% of a filler. The photosensitive resin provided by the invention can be processed by adopting photocuring three-dimensional forming additive manufacturing and other technologies while maintaining good biocompatibility and degradability, is good in processability, has important economic value and is widein application range.

Description

technical field [0001] The invention belongs to the technical field of polymer materials, and in particular relates to a light-curing 3D printing vinyl star-shaped polyphosphate composite photosensitive resin and its preparation method and application. Background technique [0002] The raw material used in the stereoscopic additive manufacturing technology (SLA) is a liquid photosensitive resin containing unsaturated bonds, and other materials can also be added to form a composite material. The computer-controlled ultraviolet laser beam is used to form the cross-section of each layer of the computer model. Scan the path point by point, so that the thin layer of resin in the scanned area undergoes photopolymerization or photocrosslinking reaction and then cures. When one layer is cured, move the worktable in the vertical direction to cover the surface of the previously cured resin with a new layer. The liquid resin is scanned and solidified layer by layer, and finally a three...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F290/06C08F222/14C08F216/12C08F222/16C08F226/10C08F2/48C08F2/44C08K3/32C08K9/04C08K3/26B33Y70/10B33Y70/00

CPCC08F290/06C08F2/48C08F2/44C08K3/32C08K9/04C08K3/26B33Y70/10B33Y70/00C08K2003/265C08K2201/005C08K2003/325C08F216/125C08F222/14C08F222/16C08F226/10

Inventor 鄢国平刘凡鄢珈睿王玉芳陈思吴江渝吴艳光

Owner WUHAN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com