Flexible degradable polymer composite resin capable of being subjected to photocuring 3D printing molding and preparation method thereof

A degradable polymer and 3D printing technology, which is applied in the direction of additive processing, can solve the problems of easy fracture and non-degradability, and achieve brittleness and easy fracture improvement, good biocompatibility, and good light-curing cross-linking characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

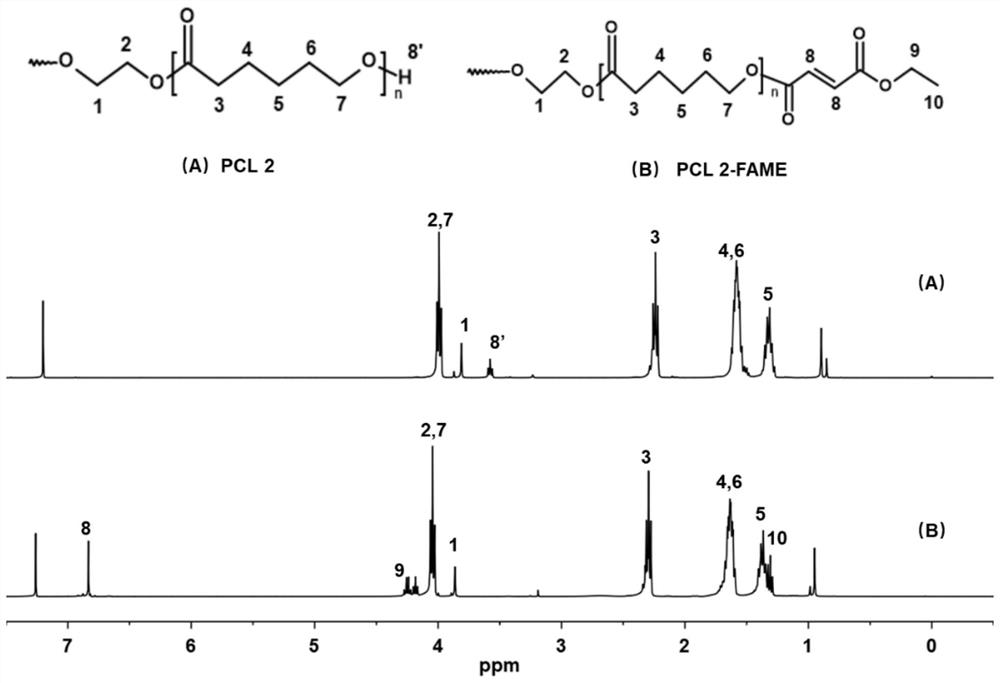

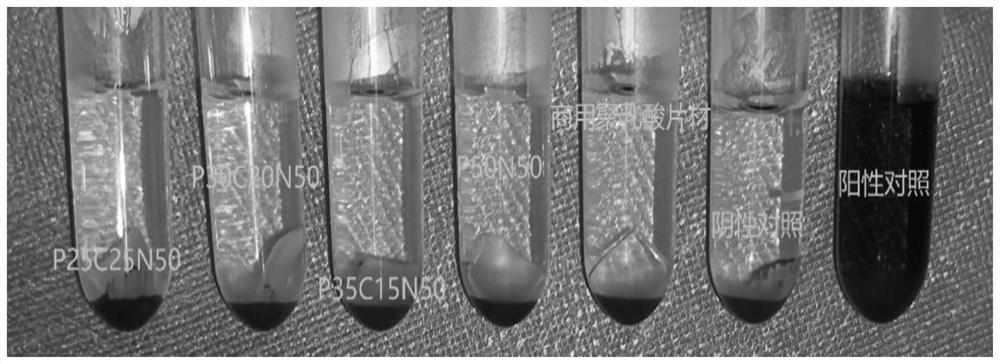

Method used

Image

Examples

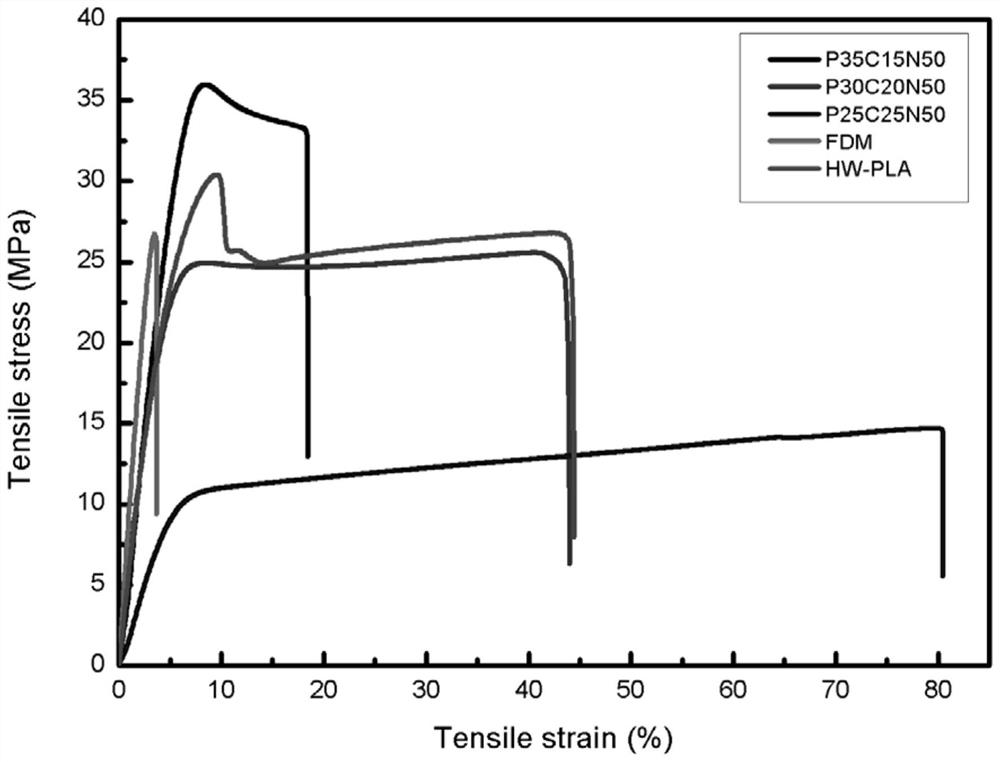

Embodiment 1

[0026] A flexible and degradable polymer composite resin that can be photocured by 3D printing includes the following components: 35g of photosensitive three-arm lactic acid oligomer modified by monoethyl fumarate, photosensitive Sexual three-arm caprolactone oligomer 15g, NVP 50g and Irgacure2959 5g.

[0027] The light curing conditions are as follows: the light intensity is 600mW / cm 2 , curing 8s.

[0028] The preparation method of the above-mentioned flexible degradable polymer composite resin that can be cured by 3D printing includes the following steps: mixing the three-arm photosensitive lactic acid oligomer, the three-arm photosensitive caprolactone oligomer and the diluent at room temperature Uniform, after light-curing 3D printing, a flexible and degradable polymer composite resin that can be formed by light-curing 3D printing is obtained.

Embodiment 2

[0030] A flexible and degradable polymer composite resin that can be photocured by 3D printing includes the following components: 30g of photosensitive three-arm lactic acid oligomer modified by methacryloyl chloride, photosensitive three-arm lactic acid oligomer modified by methacryloyl chloride Lactone oligomer 20g, NVP 50g and Irgacure 819 8g.

[0031] The light curing conditions are as follows: the light intensity is 550mW / cm 2 , curing for 10s.

[0032] The preparation method of the above-mentioned flexible degradable polymer composite resin that can be cured by 3D printing includes the following steps: mixing the three-arm photosensitive lactic acid oligomer, the three-arm photosensitive caprolactone oligomer and the diluent at room temperature Uniform, after light-curing 3D printing, a flexible and degradable polymer composite resin that can be formed by light-curing 3D printing is obtained.

Embodiment 3

[0034] A flexible and degradable polymer composite resin that can be photocured by 3D printing includes the following components: 25g of photosensitive three-arm lactic acid oligomer modified by acryloyl chloride, photosensitive three-arm caprolactone oligomer modified by acryloyl chloride Material 25g, NVP 50g and Irgacure 1700 7g.

[0035] The light curing conditions are as follows: the light intensity is 500mW / cm 2 , curing for 15s.

[0036] The preparation method of the above-mentioned flexible degradable polymer composite resin that can be cured by 3D printing includes the following steps: mixing the three-arm photosensitive lactic acid oligomer, the three-arm photosensitive caprolactone oligomer and the diluent at room temperature Uniform, after light-curing 3D printing, a flexible and degradable polymer composite resin that can be formed by light-curing 3D printing is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com