A kind of transparent writing quick-drying book page film and preparation method thereof

A book page film and transparent technology, applied in the direction of coating, etc., can solve the problems of easy bending and deformation of the film, failure to write normally, broken pens of writing strokes, etc., to achieve the effect of not being easy to pull and deform, avoiding or falling off of each layer, and smooth strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

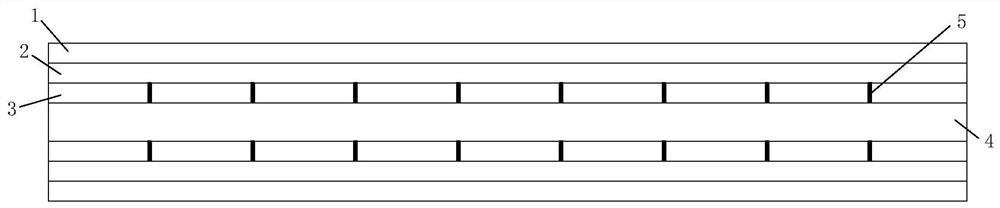

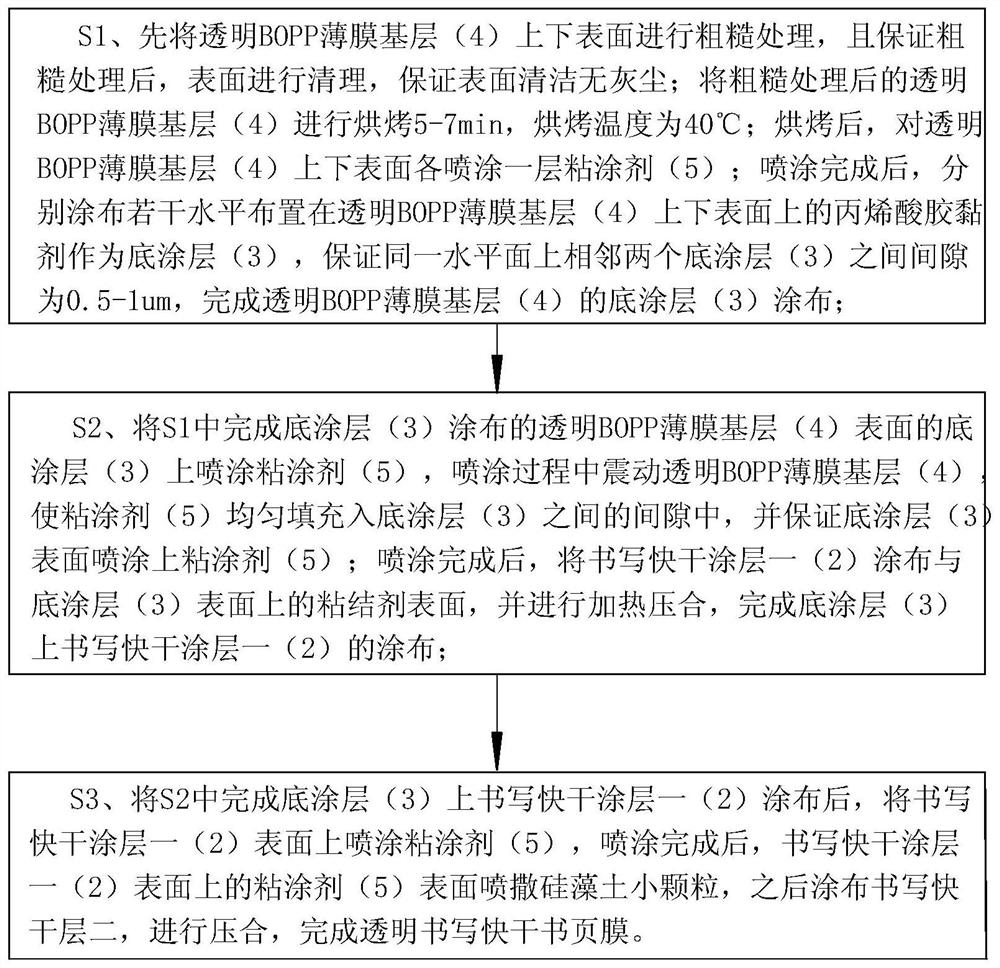

[0024] As an embodiment of the present invention, the primer layer 3 is an acrylic adhesive; the writing quick-drying coating one 2 and the writing quick-drying coating two 1 are both acrylic adhesive mixed with diatomaceous earth The mixing ratio of acrylic adhesive and diatomaceous earth is 5:1; the thickness of the writing quick-drying coating 1 and the writing quick-drying coating 2 are both 3.5-4.5um; the transparent BOPP film The thickness of the base layer 4 is 69-71um; acrylic adhesive, acrylic acid is an important organic synthesis raw material and synthetic resin monomer, and is a vinyl monomer with a very fast polymerization speed. It is the simplest unsaturated carboxylic acid, consisting of a vinyl group and a carboxyl group. Pure acrylic acid is a clear, colorless liquid with a characteristic pungent odour. It is miscible with water, alcohols, ethers and chloroform and is prepared from propylene obtained from refineries. Most of them are used to make acrylates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com