PET film with coating layer and high ink adhesive force and preparation method thereof

An adhesion and film technology, applied in coatings, polyester coatings, etc., to achieve the effects of strong ink adhesion, poor adhesion, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

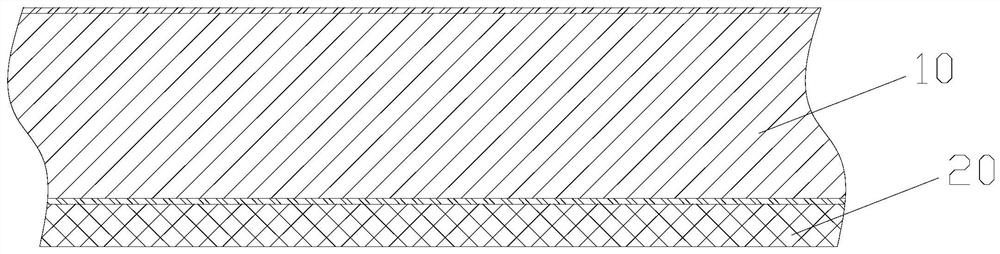

Image

Examples

preparation example Construction

[0029] A kind of preparation method of band coating high ink adhesion PET film of the present invention, comprises the steps:

[0030] Step 1): configure the coating (i.e. the aforementioned coating solution);

[0031] Step 2): processing of PET film casting;

[0032] Step 3): coating;

[0033] Step 4): drying and curing;

[0034] Step 5): (PET film cast sheet) corona treatment on the non-coated surface;

[0035] The coating solution prepared in step 1) includes the following parts by mass and preparation process: distilled water (80-90 parts) is used as a solvent, and 7-20 parts of polymethyl methacrylate (PMMA) slurry, water-soluble 1-6 parts of copolyester, 2-10 parts of leveling agent, 3-10 parts of defoamer; stir and mix for 10-60 minutes;

[0036] Step 2): PET film cast sheet treatment: After the PET film cast sheet is stretched longitudinally, in order to improve the uniformity of the layer distribution, it is necessary to corona treat the PET film cast sheet, and t...

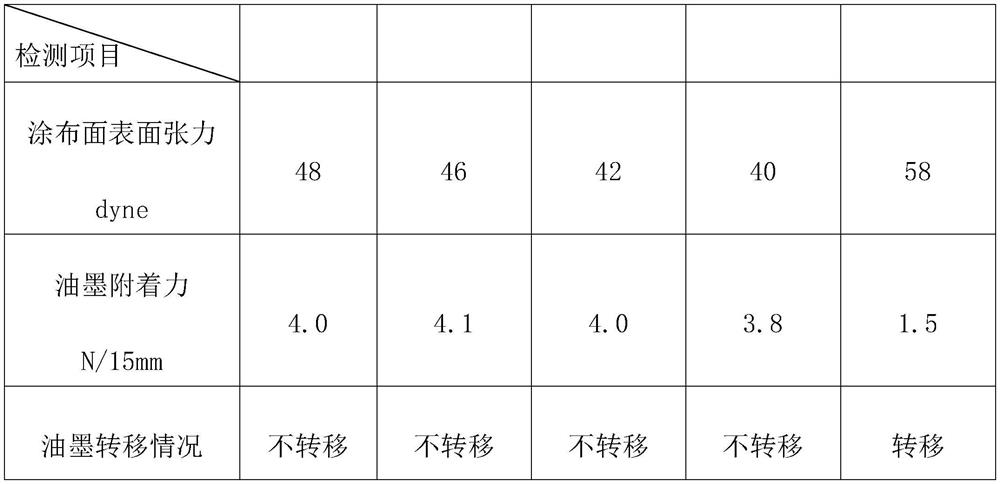

Embodiment 1

[0046] Embodiment one: the preparation method of this embodiment comprises the following steps:

[0047] Step 1): Configure the coating solution:

[0048] Prepare raw materials according to the following parts by mass:

[0049] 85 parts of deionized water, 18 parts of polymethyl methacrylate (PMMA) slurry, 6 parts of water-soluble copolyester, 8 parts of leveling agent, and 8 parts of defoamer;

[0050] Mix deionized water, polymethyl methacrylate (PMMA) slurry, water-soluble copolyester, leveling agent, and defoamer in sequence, and stir for 10-60 minutes until a uniformly dispersed coating liquid is formed;

[0051] Step 2): PET film casting processing

[0052] The PET film cast sheet is stretched longitudinally, and the PET film cast sheet that has been stretched longitudinally is subjected to corona treatment.

[0053] Step 3): Coating: Coating the coating solution prepared in step 1) on the corona surface of the PET cast sheet;

[0054] Further, the online coating metho...

Embodiment 2

[0060] Embodiment two: the preparation method of this embodiment is basically the same as embodiment one, and its difference is that the composition of coating liquid is:

[0061] 80 parts of deionized water, 20 parts of polymethyl methacrylate (PMMA) slurry, 5 parts of water-soluble copolyester, 10 parts of leveling agent, and 10 parts of defoamer. The defoamer is ethanol with a volume fraction of 90-99%. The leveling agent is an acrylate homopolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com