Hole plugging material and preparation method thereof

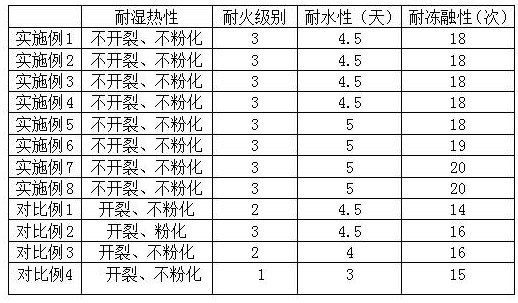

A technology for plugging materials and holes, applied in the field of hole plugging materials and their preparation, can solve the problems of poor water resistance and freeze-thaw resistance, easy deformation and falling off of materials, and unsatisfactory sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]This embodiment provides a hole plugging material, which is made of the following parts by weight of raw materials: 25-35 parts by weight of binder, 10 parts of polyacrylate, 1.5 parts of polyvinylidene fluoride, 5 parts of alumina fiber, 2 parts of ramie fiber Parts, 4.5 parts filler, 4 parts auxiliary agent, 30 parts ethyl acetate.

[0027]The filler is a mixture of tricalcium aluminate, attapulgite, and titanium dioxide, and the weight ratio of the three is: tricalcium aluminate: attapulgite: titanium dioxide is 1:0.6:0.3.

[0028]The auxiliary agent is 1.7 parts of coupling agent, 3 parts of flame retardant, and 2.5 parts of waterproof agent.

[0029]The coupling agent is silane coupling agent KH-551.

[0030]The flame retardant is chlorinated paraffin.

[0031]The waterproofing agent is bentonite.

[0032]The method for preparing a hole plugging material includes the following steps:

[0033]S1: Grind the filler and dry it, add polyacrylate, polyvinylidene fluoride, additives and 3 / 4 parts by...

Embodiment 2

[0037]This embodiment provides a hole plugging material, which is made of the following parts by weight: 28 parts of binder, 12 parts of polyacrylate, 1.8 parts of polyvinylidene fluoride, 7 parts of alumina fiber, 2.3 parts of ramie fiber, 6 parts of fillers, 5 parts of additives, 33 parts of ethyl acetate.

[0038] The filler is a mixture of tricalcium aluminate, attapulgite, and titanium dioxide, and the weight ratio of the three is: tricalcium aluminate: attapulgite: titanium dioxide is 1:0.65:0.4.

[0039]The auxiliary agent is 2 parts of coupling agent, 3.5 parts of flame retardant, and 2.5 parts of waterproof agent.

[0040]The coupling agent is silane coupling agent KH-550.

[0041]The flame retardant is chlorinated paraffin.

[0042]The waterproofing agent is sodium metasilicate.

[0043]The method for preparing a hole plugging material includes the following steps:

[0044]S1: Grind the filler and dry it, add polyacrylate, polyvinylidene fluoride, additives and 3 / 4 parts by weight of ethyl ace...

Embodiment 3

[0048]This embodiment provides a hole plugging material, which is made of the following parts by weight of raw materials: 30 parts by weight of binder, 13 parts of polyacrylate, 2 parts of polyvinylidene fluoride, 8 parts of alumina fiber, 2.5 parts of ramie fiber, 7.5 parts of filler, 6 parts of auxiliary agent, 35 parts of ethyl acetate.

[0049]The filler is a mixture of tricalcium aluminate, attapulgite, and titanium dioxide, and the weight ratio of the three is: tricalcium aluminate: attapulgite: titanium dioxide is 1:0.7:0.5.

[0050]The auxiliary agent is 2.3 parts of coupling agent, 4 parts of flame retardant, and 3 parts of waterproof agent.

[0051]The coupling agent is silane coupling agent KH-551.

[0052]The flame retardant is sodium borate.

[0053]The waterproofing agent is bentonite.

[0054]The method for preparing a hole plugging material includes the following steps:

[0055]S1: Grind the filler and dry it, add polyacrylate, polyvinylidene fluoride, additives and 3 / 4 parts by weight o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com