Modified polypropylene wave crest double-wall pipe and preparation method of modified polypropylene material thereof

A technology of polypropylene material and peak tube, which is applied in the direction of electrical components, etc., can solve the problems of impact resistance and compression resistance that need to be modified, the processing technology of double-walled pipes is complicated, and the weight of double-walled pipes is increased, so as to achieve light weight , simple structure and small consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

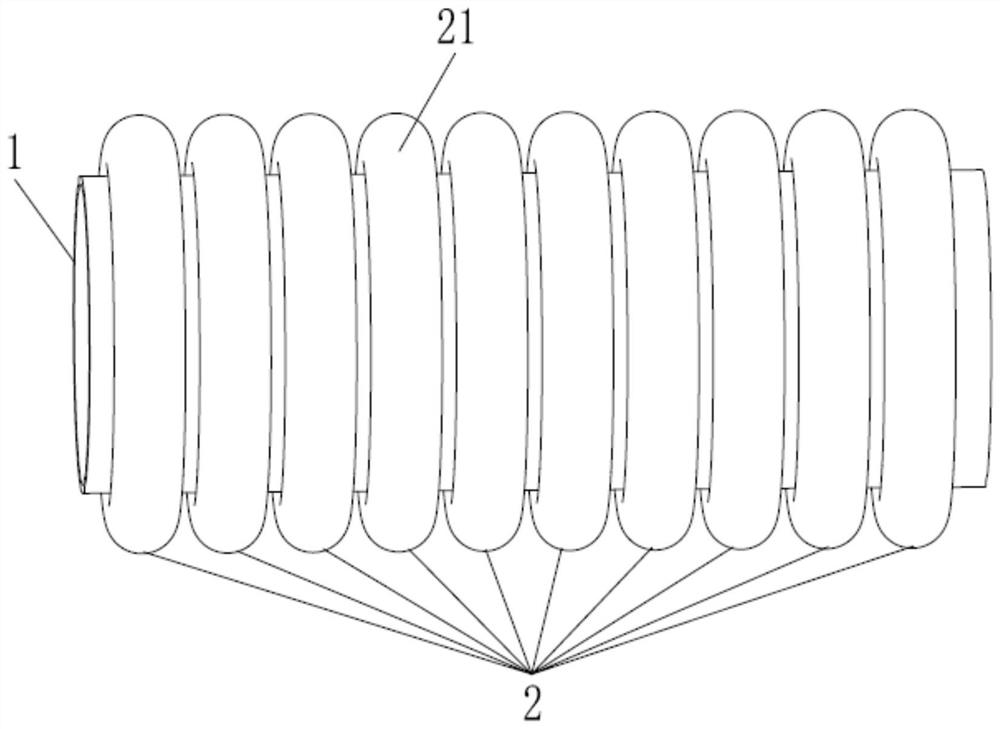

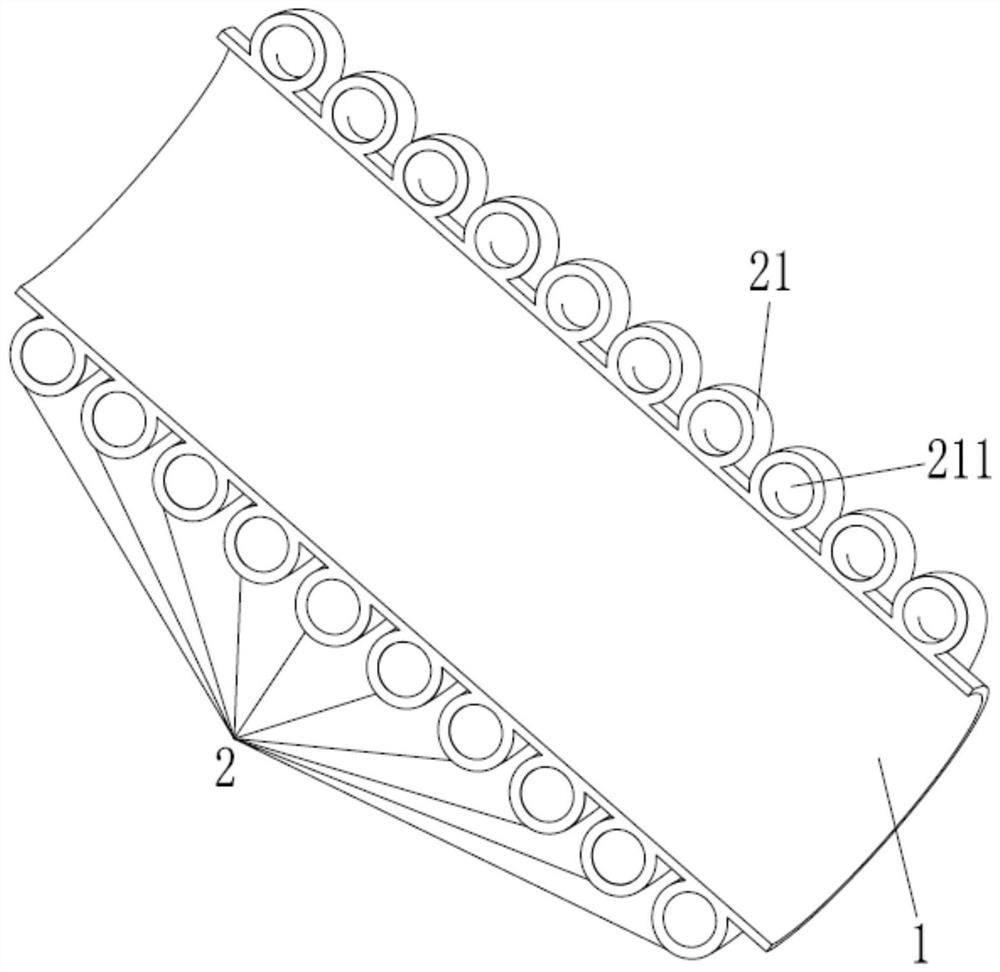

[0035] A kind of modified polypropylene peak double-wall pipe of the present embodiment, refer to its structure Figure 1-2 , including inner tube 1 and outer tube 2. Preferably, the inner tube 1 is in the shape of a hollow cylinder, and the inner tube 1 in the shape of a hollow cylinder is more convenient for processing and forming, and is suitable for mass production, and the inner peripheral wall of the inner tube 1 in the shape of a hollow cylinder is smooth and has no corners and other obstacles, it is convenient to quickly pass through multiple cables, and then play a role in protecting the cables.

[0036] Wherein, the outer tube 2 includes a plurality of independent peak tube bodies 21, each peak tube body 21 surrounds the outer peripheral wall of the inner tube 1, and each peak tube body 21 is arranged at intervals along the length direction of the inner tube 1 on the inner tube 1. The outer peripheral wall, so that the outer peripheral wall of the inner tube 1 forms...

Embodiment 2

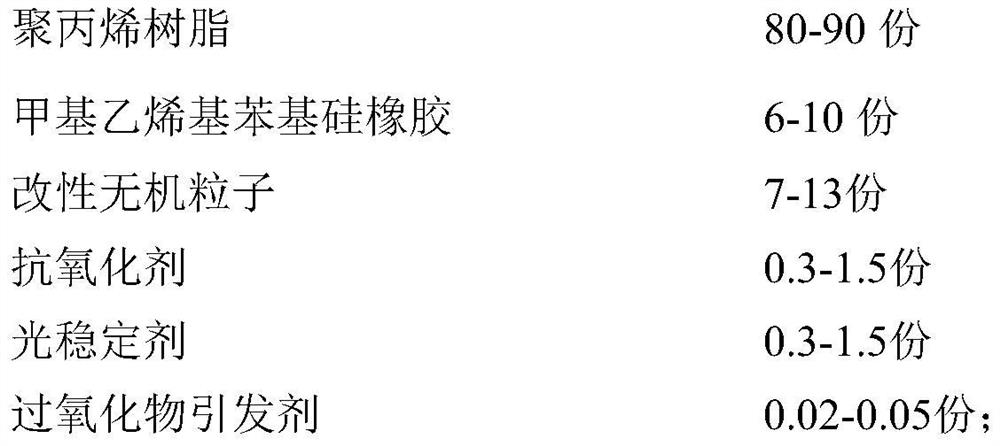

[0053] A modified polypropylene peak double-wall pipe in this embodiment has the same structure as that of Embodiment 1, and the difference between it and Embodiment 1 is that the modified polypropylene material is composed of the following components in parts by weight:

[0054]

[0055] Wherein, the modified inorganic particles are composed of the following components in parts by weight:

[0056]

[0057] Among them, the polypropylene resin is preferably PP-R; the phenyl content in the methyl vinyl phenyl silicone rubber is preferably 15% (ie C 6 h 5 / Si=15%).

[0058] Wherein, the peroxide crosslinking agent is dicumyl peroxide and 2,5-dimethyl-2,5-bis(t-butylperoxy)hexyne mixed at a mass ratio of 1:1. The antioxidant is antioxidant 1076. The light stabilizer is light stabilizer 770.

[0059] The preparation method of the modified polypropylene material comprises the following preparation steps:

[0060] Step S1: Mix and grind hollow glass microspheres and light ...

Embodiment 3

[0064] A modified polypropylene peak double-wall pipe in this embodiment has the same structure as that of Embodiment 1, and the difference between it and Embodiment 1 is that the modified polypropylene material is composed of the following components in parts by weight:

[0065]

[0066] Wherein, the modified inorganic particles are composed of the following components in parts by weight:

[0067]

[0068] Among them, the polypropylene resin is preferably PP-R; the phenyl content in the methyl vinyl phenyl silicone rubber is preferably 12% (ie C 6 h 5 / Si=12%).

[0069] Wherein, the peroxide crosslinking agent is dicumyl peroxide and dicumyl peroxide mixed in a mass ratio of 1:1. The antioxidant is antioxidant 168 and antioxidant 1076 mixed in mass ratio. The light stabilizer is light stabilizer 2002.

[0070] The preparation method of the modified polypropylene material comprises the following preparation steps:

[0071] Step S1: Mix and grind hollow glass microsp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com