A kind of preparation method of high combustion rate biomass fuel with internal locking form for power generation

A biomass fuel, combustion rate technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of low effective utilization rate of fuel, low actual calorific value, insufficient development of biofuels, etc., to improve combustion efficiency and utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

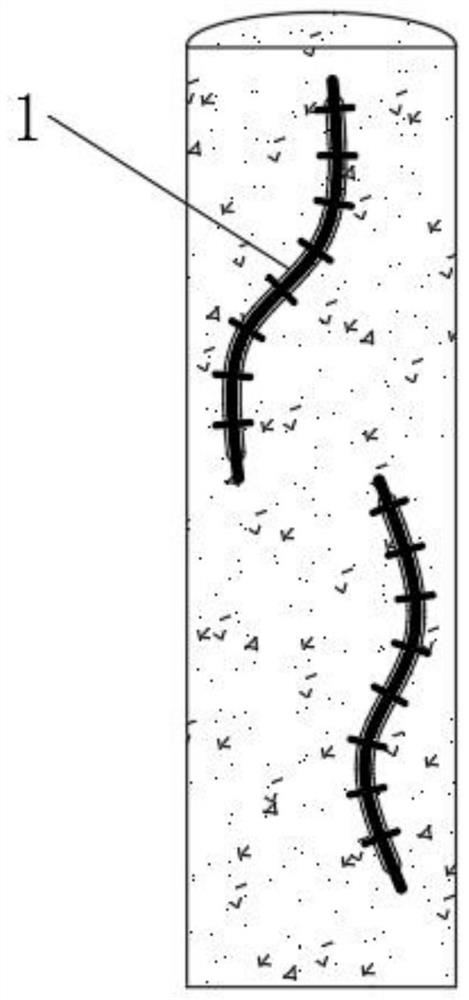

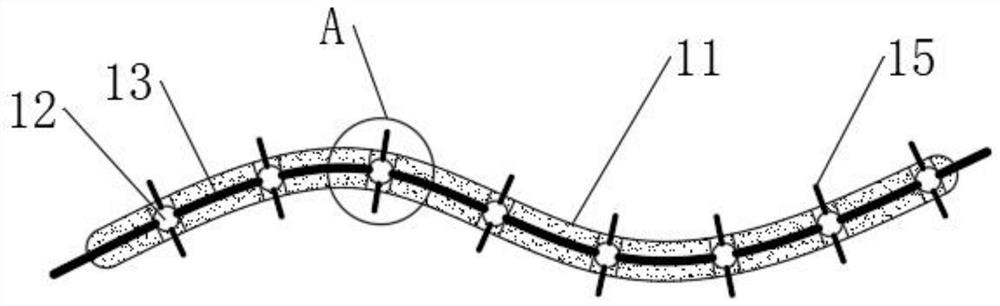

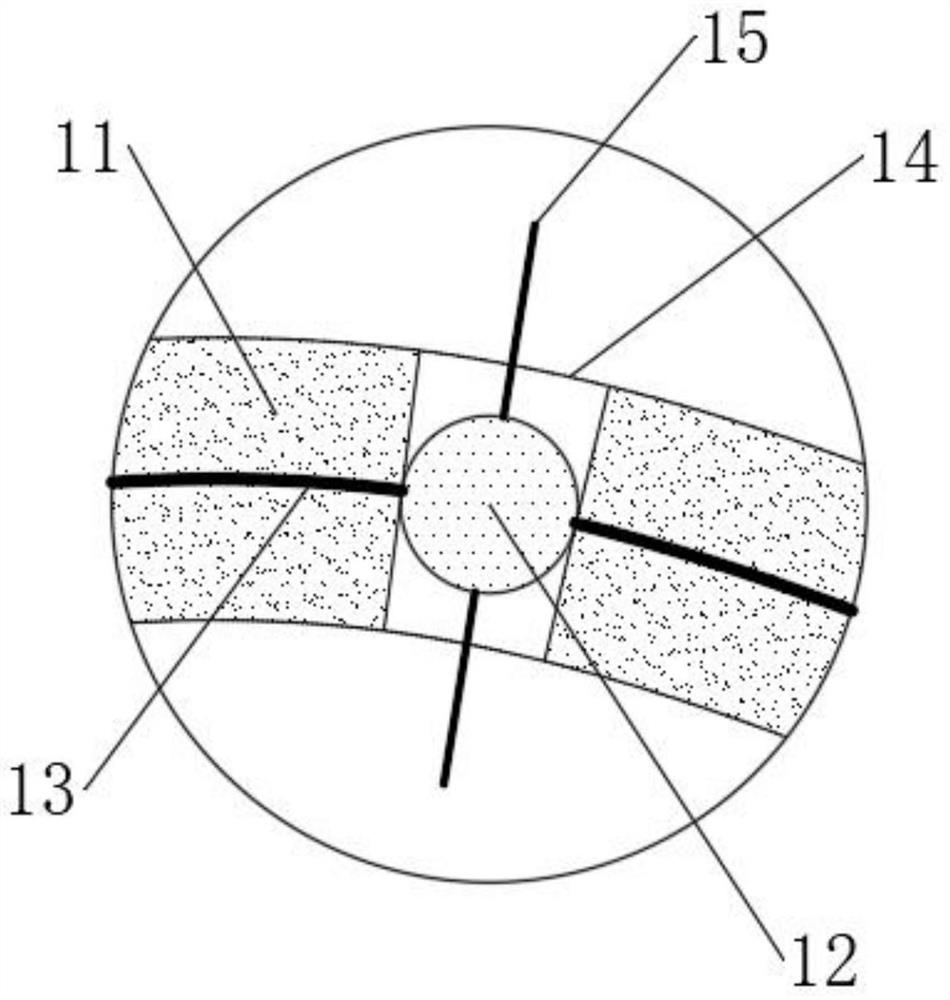

[0041] see figure 1 , a kind of preparation method of the high combustion rate biomass fuel of interlocking form for generating electricity, comprises the following steps:

[0042] S1. Collect agricultural raw materials and carry out natural drying first, after drying, cut and pulverize and pass through an 80-mesh sieve to make raw material powder for later use;

[0043] S2. Mixing the raw material powder with dry livestock and poultry manure and pond sludge and stirring evenly, and fermenting in a sealed environment at 45° C. for 2 days to obtain a fermentation product;

[0044] S3. After the fermentation product is uniformly mixed with the combustion enhancer, loosening agent and anti-coking additive, microwave treatment is performed, and after completion, it is taken out and dried until the water content is lower than 5%;

[0045] S4. After drying, the material is taken out and evenly mixed with the lock-shaped combustion-supporting rod 1, and then obtained by extrusion mo...

Embodiment 2

[0056] see figure 1 , a kind of preparation method of the high combustion rate biomass fuel of interlocking form for generating electricity, comprises the following steps:

[0057] S1. Collect agricultural raw materials and carry out natural drying first, after drying, cut and pulverize and pass through an 80-mesh sieve to make raw material powder for later use;

[0058] S2. Mixing the raw material powder with dry livestock and poultry manure and pond sludge and stirring evenly, and fermenting in a sealed environment at 45°C for 3 days to obtain a fermentation product;

[0059] S3. After the fermentation product is evenly mixed with the combustion enhancer, bulking agent and anti-coking additive, microwave treatment is performed, and after completion, it is taken out and dried until the water content is lower than 5%;

[0060] S4. After drying, the material is taken out and evenly mixed with the lock-shaped combustion-supporting rod 1, and then obtained by extrusion molding t...

Embodiment 3

[0068] see figure 1 , a kind of preparation method of the high combustion rate biomass fuel of interlocking form for generating electricity, comprises the following steps:

[0069] S1. Collect agricultural raw materials and carry out natural drying first, after drying, cut and pulverize and pass through an 80-mesh sieve to make raw material powder for later use;

[0070] S2. Mixing the raw material powder with dry livestock and poultry manure and pond sludge and stirring evenly, and fermenting in a sealed environment at 50° C. for 5 days to obtain a fermentation product;

[0071] S3. After the fermentation product is evenly mixed with the combustion enhancer, bulking agent and anti-coking additive, microwave treatment is performed, and after completion, it is taken out and dried until the water content is lower than 5%;

[0072] S4. After drying, the material is taken out and evenly mixed with the lock-shaped combustion-supporting rod 1, and then obtained by extrusion molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com