Die-cutting machine for printing

A die-cutting machine, hot stamping machine technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of messy tearing of paper burrs, labor-intensive, blurred printing surface, etc., to improve processing efficiency and Pass rate, improve smoothness and uniformity, and improve the effect of underwriting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

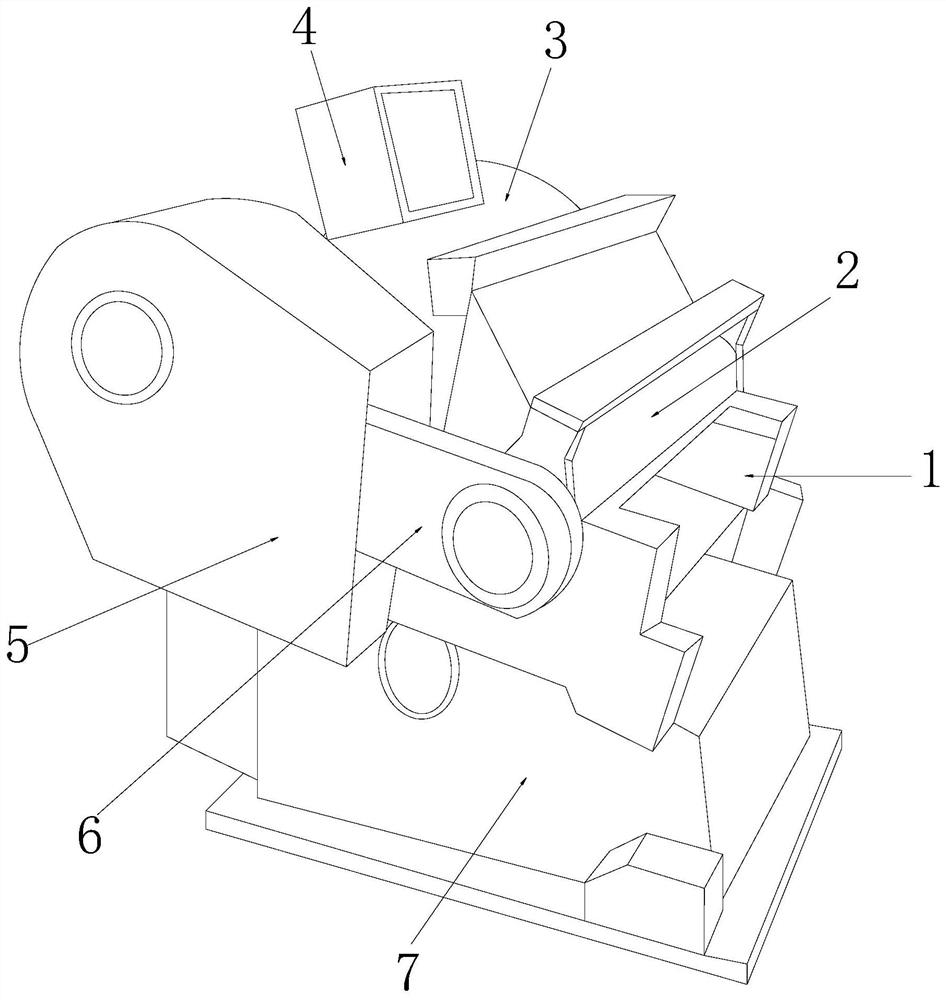

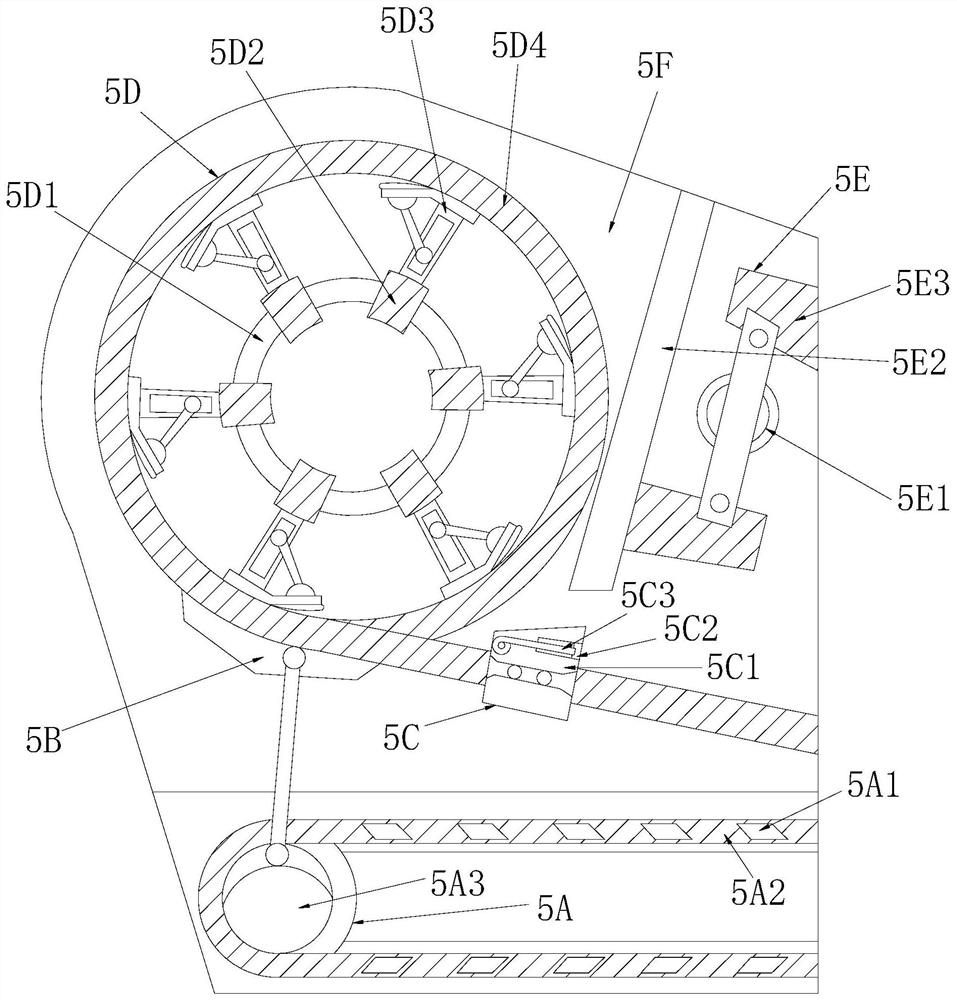

[0033] see Figure 1-Figure 6, the present invention provides a die-cutting machine for printing, its structure includes: a die-cutting guillotine table 1, a continuous supply roller 2, a printing drum 3, a distribution box 4, a stamping film frame 5, a conveyor belt 6, The base column block 7, the stamping film frame 5 is nested on the front side of the printing drum 3 and the axes are collinear, the distribution box 4 is installed on the top of the printing drum 3, and the connecting The supply roller 2 is mechanically connected to the printing drum 3 through the conveyor belt 6, the conveyor belt 6 is inserted on the right side of the stamping film frame 5 and is on the same vertical plane, and the die-cutting guillotine table 1 is nested in the On the top of the base column block 7, the continuous supply roller 2 is installed on the top of the die-cutting guillotine platform 1, and the stamping film frame 5 is provided with a fin conveyor belt 5A, a roller support bar 5B, ...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a kind of die-cutting machine for printing, other respects are identical with embodiment 1, and difference is:

[0041] see figure 2 , the hinged support wheel frame 5E is composed of a hinged wheel body 5E1, an inclined frame liner 5E2, and a folding frame support plate seat 5E3. On the same vertical plane, the folded frame support plate seat 5E3 is installed on the right side of the inclined frame liner plate 5E2, and the folding frame support plate seat 5E3 is pressed and covered by the sloped frame liner plate 5E2 to form the effect of protecting the printing cylinder on the side. , and adapt to the overall disk wheel to form the effect of carding around the paper surface.

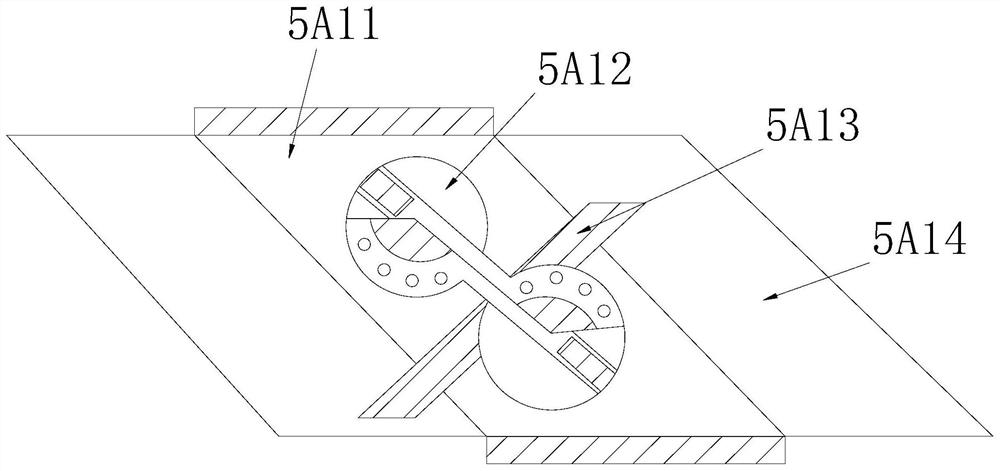

[0042] see Figure 6 , the hinged wheel body 5E1 is composed of a wheel frame ring 5E11, a wing support plate 5E12, a three-lobe wheel core 5E13, and a brush pole block 5E14, and the three-lobe wheel core 5E13 is installed inside the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com