Three-symmetric-point hydraulic rolling head

A rolling head and rolling technology, applied in the direction of fluid pressure actuation device, etc., can solve problems such as heavy wear, and achieve the effects of improving mechanical properties, improving surface grain refinement, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

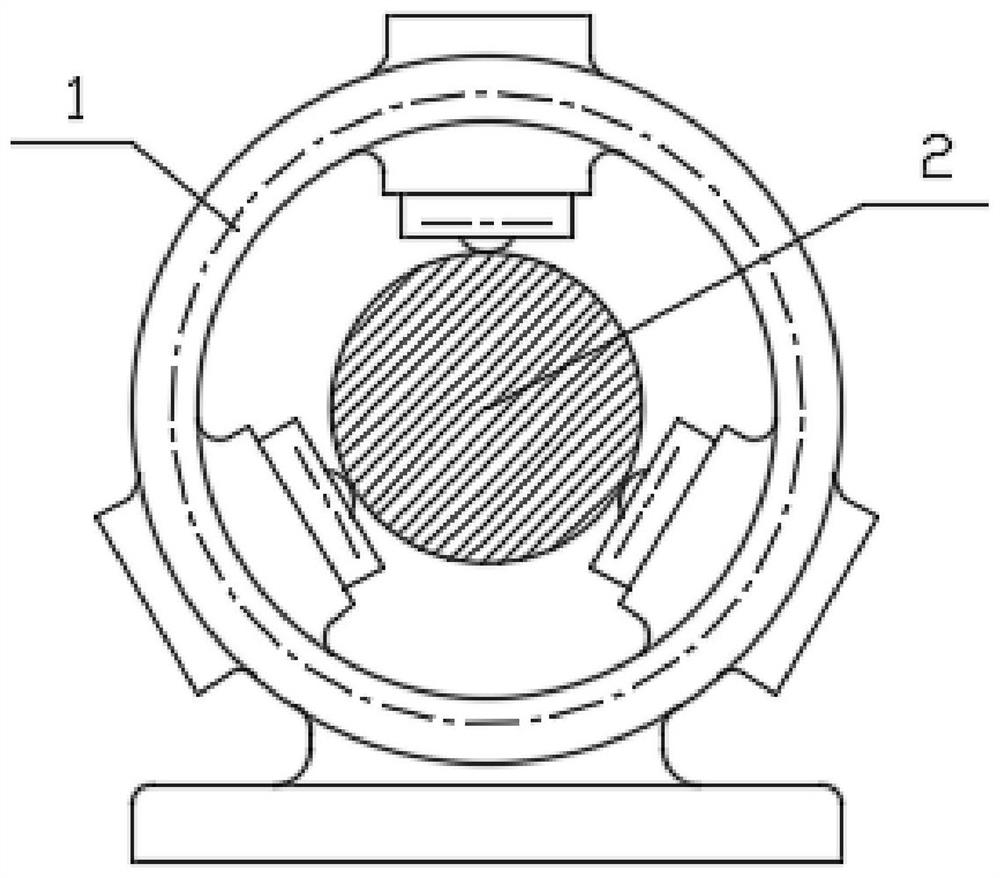

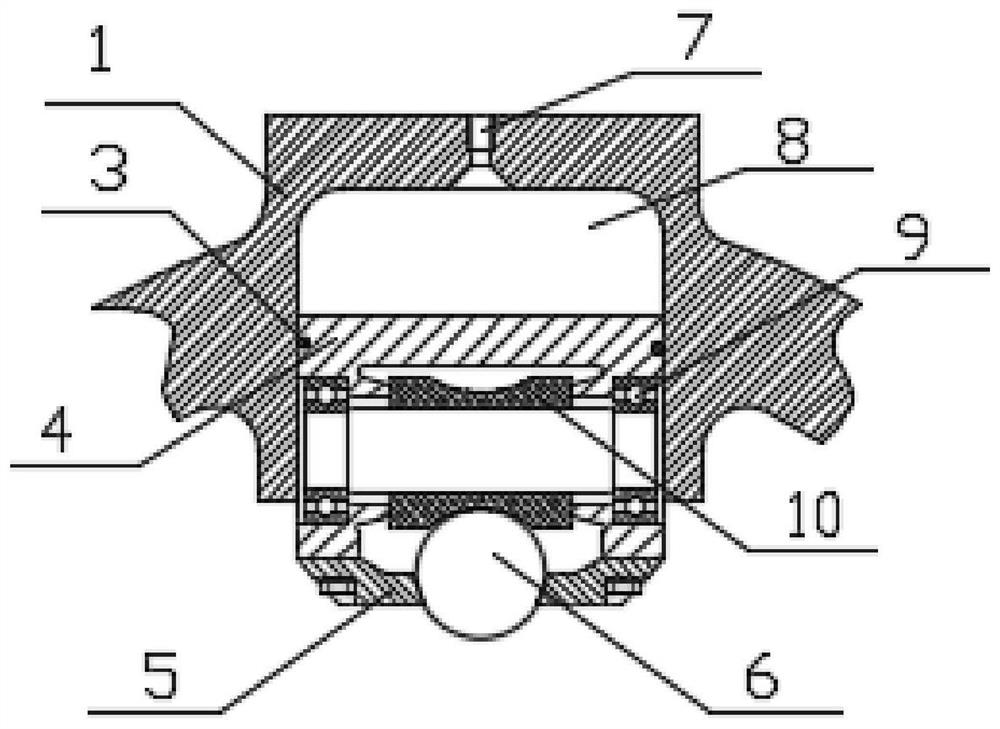

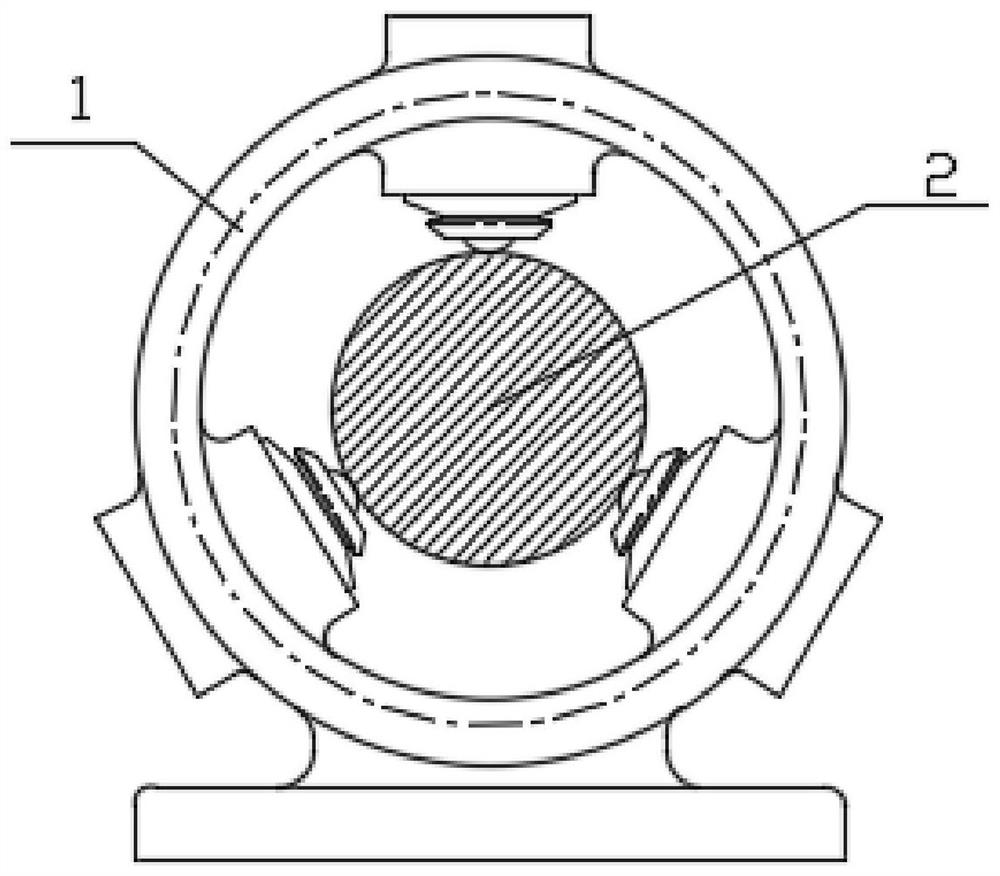

[0026] The three-symmetric point hydraulic rolling head provided by the preferred embodiment of the present invention, the three-symmetric point hydraulic rolling head includes a support seat 1 and a rolling product 2, and three rolling steel balls 6 are arranged on the support seat 1 , evenly distributed on the outer circle of the rolling product 2, and the resultant force is zero; the oil inlet 7 is set on the support seat 1, and the high-pressure oil chamber 8 is formed between the oil inlet 7 and the rolling steel ball 6, and the high-pressure oil chamber 8 The piston 4 is arranged near the rolling steel ball 6, and the piston 4 and the rolling steel ball 6 are closely attached to the outside of the steel ball, and a φ0.15~φ0.30 through hole is drilled in the center of the pressing axis of the piston 4.

[0027] When working: Compared with the traditional design, this scheme abandons the way that the single-row ball bearing 9 and the support roller 10 are in direct contact ...

Embodiment 2

[0029] On the basis of the first embodiment, this embodiment further includes a support cover 5 arranged at the bottom of the piston 4 . The sealing ring 3 is arranged between the piston 4 and the support seat 1 .

[0030] When working: Due to the leakage of hydraulic oil between the steel ball and the spherical surface of the integral piston, it is necessary to control the pressure value of the steel ball. The spherical precision of the high-precision steel ball and the piston must be selected to control the gap between the two spherical surfaces at 0.015-0.02mm. At the same time, the hydraulic oil needs to be greater than 15-20Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com