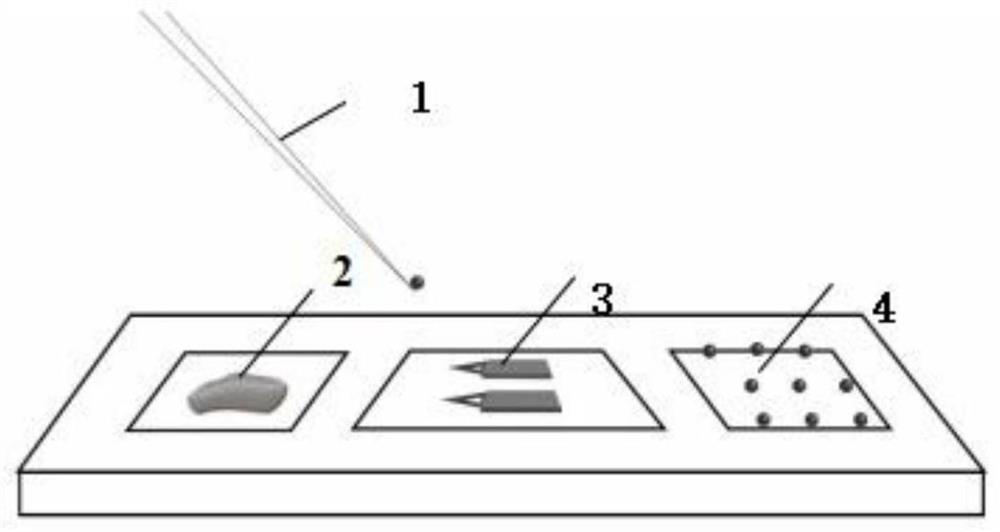

Atomic force microscope colloid probe surface modification method

An atomic force microscope, surface modification technology, applied in scanning probe technology, scanning probe microscopy, measuring devices, etc. Large roughness and other problems, to achieve high universality, improve yield and mass production efficiency, and achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

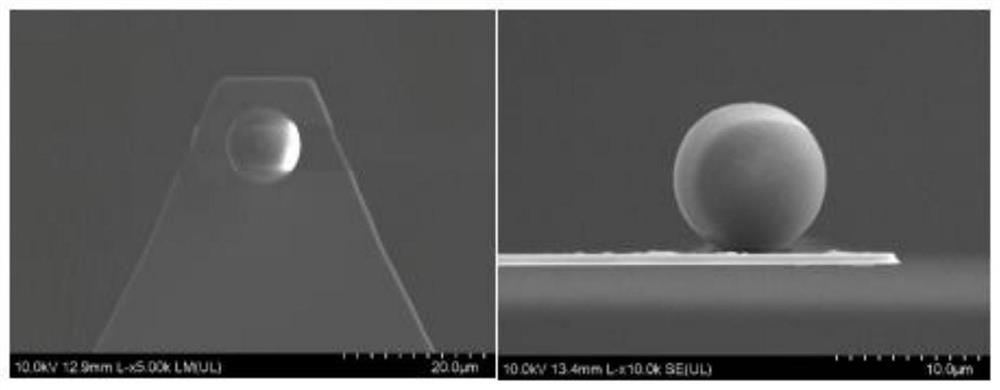

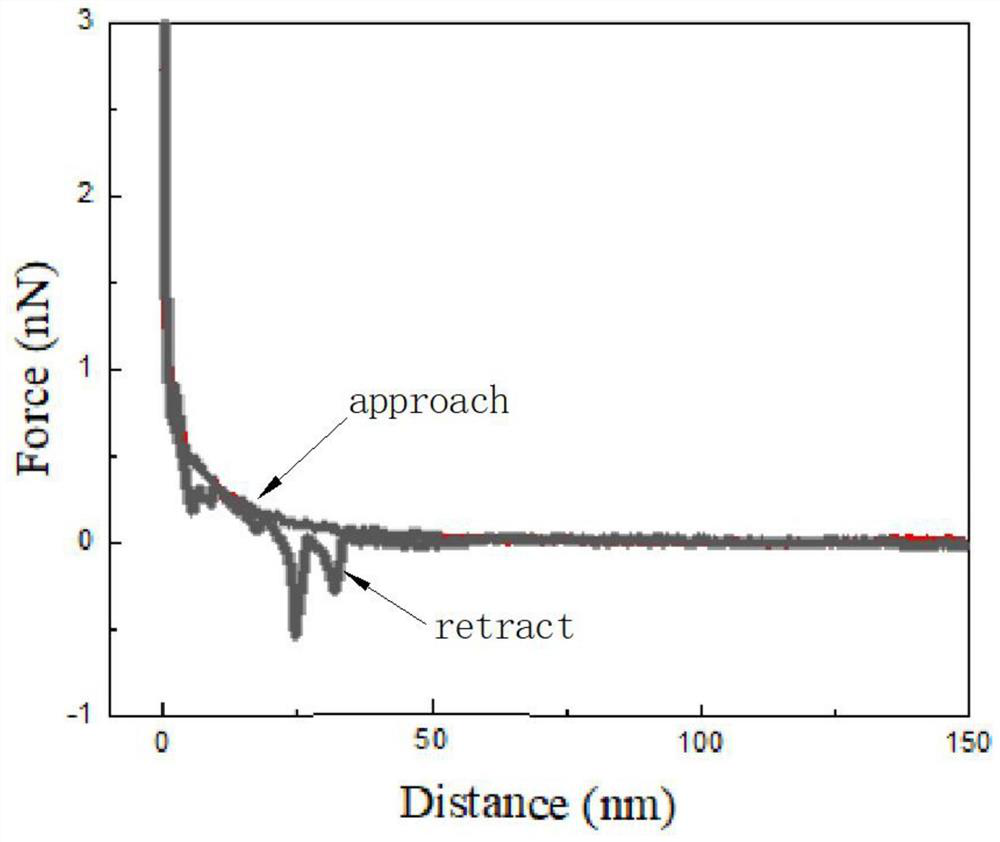

[0032] A method for surface modification of an atomic force microscope colloidal probe, comprising the steps of:

[0033] 1) Preparation of colloidal microspheres wrapped in hematite film: at room temperature, slowly to 0.01M FeCl 3 A minimum amount of 1M NaOH solution was added to the solution to pH7. will be 5×10 7 / ml 5μm silica microspheres were added to 1mL FeOOH solution and ultrasonicated for 10min. Put the centrifuge tube containing the sample solution into a centrifuge and centrifuge at a centrifugal speed of 5000 rpm for 5 minutes. After repeated washing with ultrapure water for 3 times, the colloidal microspheres loaded with iron oxyhydroxide were placed in an oven at a temperature of 100 degrees Celsius and dried for 12 hours.

[0034] 2) Place the colloidal microspheres wrapped with the hematite nanofilm in the tannic acid modification solution, and shake slowly for 24 hours. The centrifuge tube containing the sample solution was put into a centrifuge and cent...

Embodiment 2

[0042] A colloidal microsphere probe modification method for an atomic force microscope, comprising the steps of:

[0043] 1) Preparation of colloidal microspheres wrapped in hematite film: at room temperature, slowly to 0.01M FeCl 3 A minimum amount of 1M NaOH solution was added to the solution to pH7. will be 5×10 7 / ml 2μm polyethylene terephthalate microspheres were added to 0.5mL FeOOH solution and ultrasonicated for 20min. Put the centrifuge tube containing the sample solution into a centrifuge and centrifuge at a centrifugal speed of 5000 rpm for 10 minutes. After repeated washing with ultrapure water for 3 times, the colloidal microspheres loaded with iron oxyhydroxide were placed in an oven at a temperature of 100 degrees Celsius and dried for 12 hours.

[0044] 2) Place the colloidal microspheres wrapped with the hematite nanofilm in the humic acid modification solution, and shake slowly for 48 hours. The centrifuge tube containing the sample solution was put int...

Embodiment 3

[0053] A colloidal microsphere probe modification method for an atomic force microscope, comprising the steps of:

[0054] 1) Preparation of colloidal microspheres wrapped in hematite film: at room temperature, slowly to 0.01M FeCl 3 A minimum amount of 1M NaOH solution was added to the solution to pH7. will be 5×10 7 / ml of glass microspheres with a diameter of 10 μm was added to 2 mL of FeOOH solution and ultrasonicated for 30 min. Put the centrifuge tube containing the sample solution into a centrifuge and centrifuge at a centrifugal speed of 5000 rpm for 5 minutes. After repeated washing with ultrapure water for 3 times, the colloidal microspheres loaded with iron oxyhydroxide were placed in an oven at a temperature of 100 degrees Celsius and dried for 12 hours.

[0055] 2) Place the colloidal microspheres wrapped with the hematite nanofilm in the fulvic acid modification solution, and shake slowly for 24 hours. The centrifuge tube containing the sample solution was pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com