Metal-free phthalocyanine-graphene nonlinear optical composite material as well as preparation method and application thereof

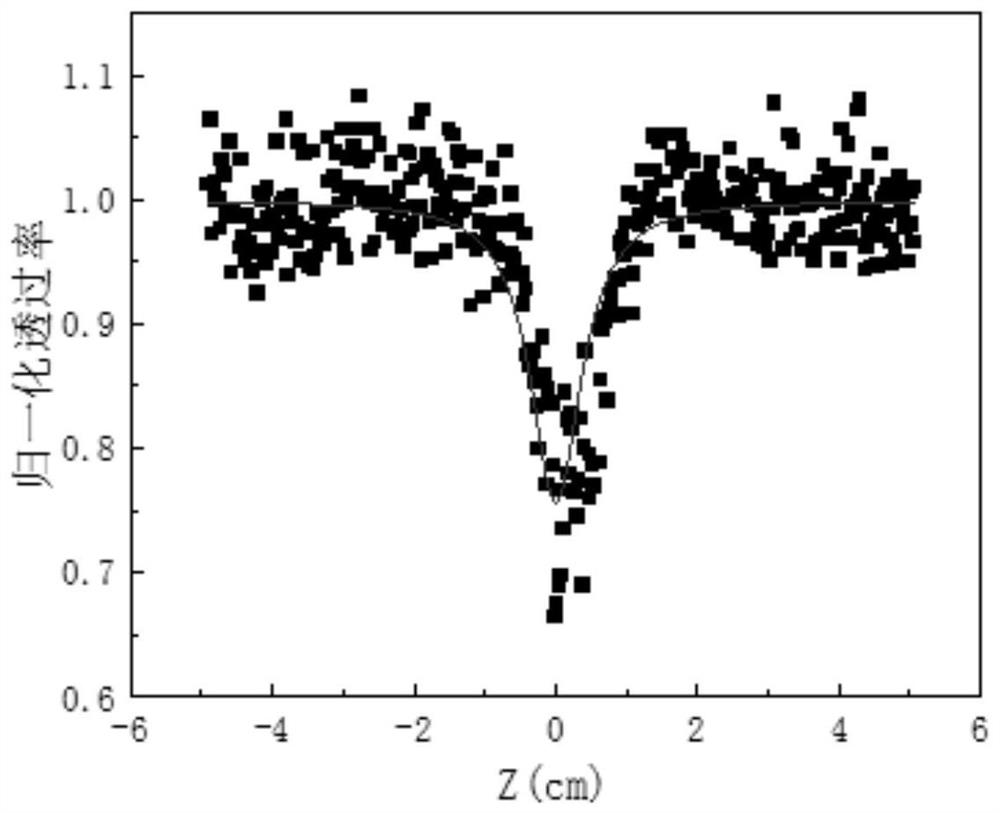

A technology of nonlinear optics and composite materials, applied in the field of metal-free phthalocyanine-graphene nonlinear optical composite materials and their preparation, can solve the problems of low damage threshold, long response time, poor third-order nonlinear optical performance, etc. Achieve the effects of stable performance, simple preparation method and good third-order nonlinear optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

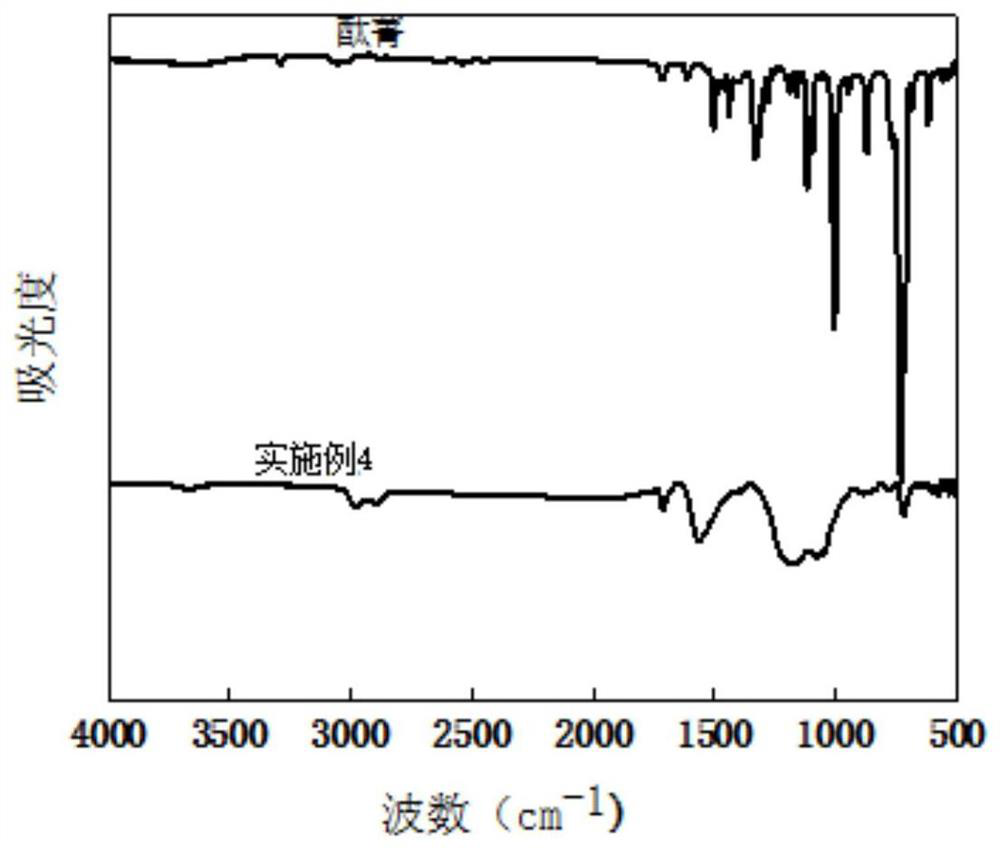

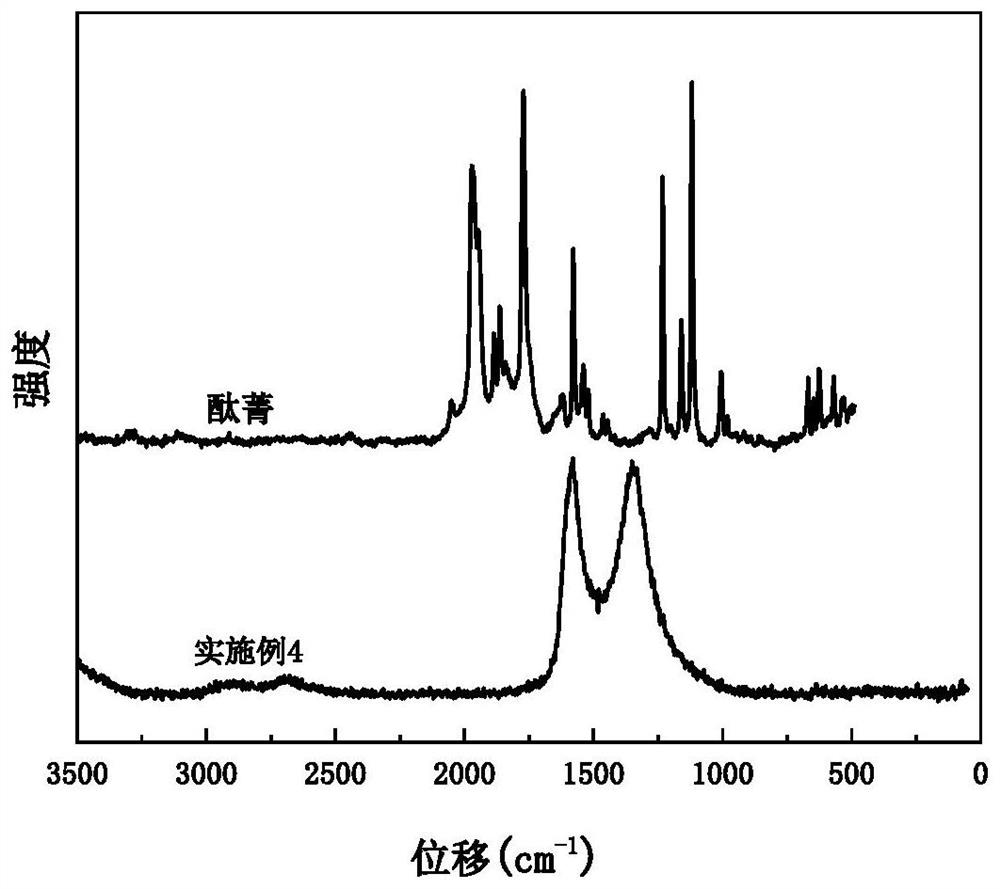

[0037] The present invention also provides a method for preparing the metal-free phthalocyanine-graphene nonlinear optical composite material, wherein phthalocyanine and graphene are non-covalently combined to obtain the metal-free phthalocyanine-graphene nonlinear optical composite material. Specifically, the following steps may be included:

[0038] Step 1, adding phthalocyanine, graphene and concentrated sulfuric acid into the reactor, stirring in a water bath at 40-80°C for 20-30 hours to obtain a liquid-solid mixture, the mass ratio of phthalocyanine and graphene is 1:1;

[0039] Step 2. After cooling the liquid-solid mixture obtained in Step 1 to room temperature, add dropwise to ice water, stir at room temperature for 0.5-1.5 h to quench, and obtain a crude product;

[0040] Step 3: filter the crude product under reduced pressure, wash with deionized water until neutral, then wash with ethanol, and dry to obtain a metal-free phthalocyanine-graphene nonlinear optical compo...

Embodiment 1

[0049] Step 1: Add 200 mg of phthalocyanine, 200 mg of physical double-layer graphene (PGN2) and 30 ml of concentrated sulfuric acid into the reactor, and stir in a water bath at 60° C. for 24 hours to obtain a liquid-solid mixture.

[0050] Step 2. Cool the liquid-solid mixture prepared in Step 1 to room temperature, drop it into a beaker containing 50 ml of ice water at a rate of 1 drop per second, and stir at room temperature for 1 h to obtain a crude product.

[0051] Step 3: filter the crude product under reduced pressure, wash it with deionized water until neutral, then wash it with ethanol, and dry it in an oven at 50°C for 12 hours to obtain a metal-free phthalocyanine-graphene nonlinear optical composite material.

Embodiment 2

[0053] Step 1: Add 200 mg of phthalocyanine, 200 mg of physical four-layer graphene (PGN4) and 30 ml of concentrated sulfuric acid into the reactor, and stir in a water bath at 60° C. for 24 hours to obtain a liquid-solid mixture.

[0054] Step 2. Cool the liquid-solid mixture prepared in Step 1 to room temperature, drop it into a beaker containing 50 ml of ice water at a rate of 1 drop per second, and stir at room temperature for 1 h to obtain a crude product.

[0055] Step 3: filter the crude product under reduced pressure, wash it with deionized water until neutral, then wash it with ethanol, and dry it in an oven at 50°C for 12 hours to obtain a metal-free phthalocyanine-graphene nonlinear optical composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com