Epitaxial circulating fluidized bed semi-dry desulfurization and dust removal system and desulfurization and dust removal method

A circulating fluidized bed and semi-dry desulfurization technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle filtration, etc., can solve problems such as difficulty in hoisting, high cost, and complicated installation procedures of desulfurization towers, and achieve cost reduction , reduce cost, reduce the effect of the number of bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

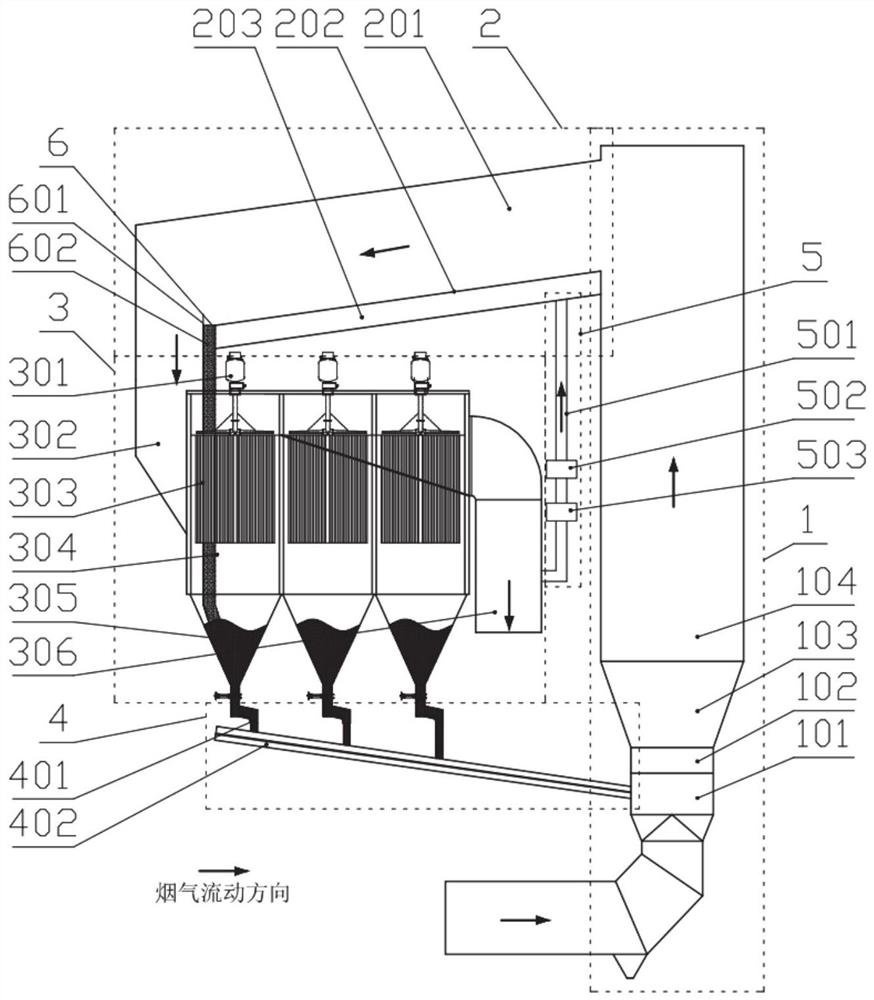

Embodiment 1

[0052] An epitaxial circulating fluidized bed semi-dry desulfurization and dust removal system, which is equipped with a desulfurization tower system 1, a desulfurization tower extension system 2, a bag filter system 3, a material return system 4, and an extension fluidization system 5; the desulfurization tower system 1 consists of The return section 101, the acceleration section 102, the gradual expansion section 103, and the straight section 104 are composed; the desulfurization tower extension system 2 is composed of the extension section 201, the fluidization plate 202, and the fluidization air chamber 203; the bag filter system 3 is composed of a bag cleaning System 301, dust collector inlet 302, cloth bag 303, cloth bag warehouse 304, ash hopper 305, dust collector outlet flue 306; return system 4 is composed of return valve 401, fluidization chute 402; epitaxial fluidization system 5 It is composed of pipeline 501, heater 502 and booster fan 503; desulfurizer overflow s...

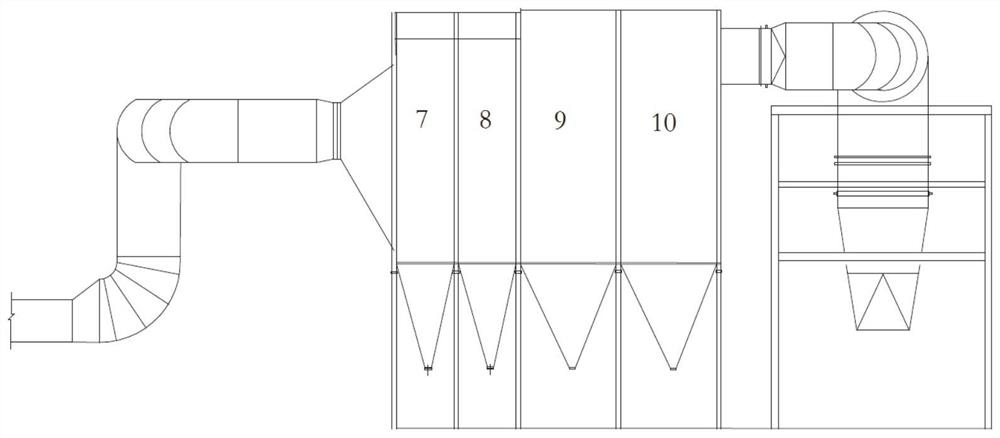

Embodiment 2

[0055] An epitaxial circulating fluidized bed semi-dry desulfurization and dust removal system, which is equipped with a desulfurization tower system 1, a desulfurization tower extension system 2, a bag filter system 3, a material return system 4, and an extension fluidization system 5; the desulfurization tower system 1 consists of The return section 101, the acceleration section 102, the gradual expansion section 103, and the straight section 104 are composed; the desulfurization tower extension system 2 is composed of the extension section 201, the fluidization plate 202, and the fluidization air chamber 203; the bag filter system 3 is composed of a bag cleaning System 301, dust collector inlet 302, cloth bag 303, cloth bag warehouse 304, ash hopper 305, dust collector outlet flue 306; return material system 4 is composed of return material valve 401, fluidization chute 402; epitaxial fluidization system 5 It is composed of pipeline 501, heater 502 and booster fan 503; desul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com