Method for treating wine chateau wastewater

A treatment method, wine technology, applied in food industry wastewater treatment, multi-stage water treatment, water treatment parameter control, etc., can solve the problems of poor wastewater treatment in wineries, achieve poor treatment effects and reduce operating costs , the effect of improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

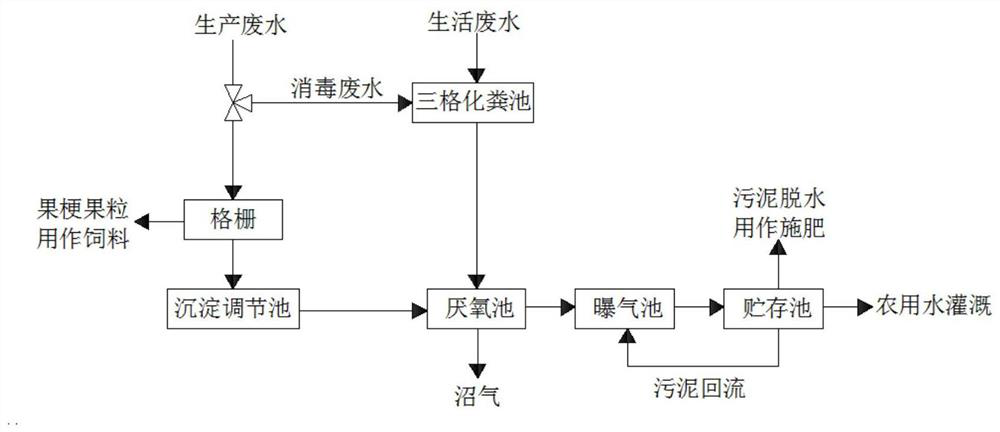

[0033] The invention provides a treatment method for winery wastewater, which is used to treat production wastewater and domestic sewage produced by wineries, such as figure 1 As shown, the wastewater is first mixed with the domestic sewage treated by anaerobic fermentation and then anaerobic treatment is performed. After the anaerobic treatment, the mixed wastewater is aerated, and the water is discharged after sedimentation. Further explanation, the COD concentration in the mixed wastewater is 1000-1800mg / L, the BOD concentration is 850-1000mg / L, and the SS concentration is 200-450mg / L. The production wastewater here mainly includes wine fermentation wastewater and cleaning wastewater generated after cleaning production equipment. Fermentation wastewater mainly includes organic acids, sugars and their transformation substances, and cleaning wastewater mainly includes cleaning agents, disinfectants, etc.

[0034] Such as figure 1 As shown, after the production wastewater is...

Embodiment 2

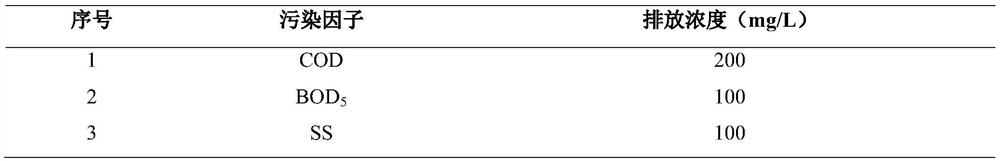

[0047] The basic content of embodiment 2 is the same as embodiment 1, and its difference is that the processing object of this embodiment is the wastewater produced by a certain winery in Yongning County, Yinchuan City. The winery has an annual output of 990 tons of wine, and the main production period of the project is mainly concentrated in September-October each year. After accounting, the domestic water consumption of the project is about 216m 3 / a, if the domestic sewage accounts for 80% of the water consumption, the domestic sewage production is 172.8m 3 / a. The production wastewater of the project mainly comes from production line equipment (tank) cleaning, ground washing and bottle washing in the filling line. Among them, the production line equipment (tank) cleaning water is 343m 3 / a, the water consumption for ground flushing is about 146m 3 / a, the water consumption of bottle washing in the filling line is about 80m 3 / a, natural gas boiler water 200m 3 / a. Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com