A kind of alumina ceramic skeleton for transformer and preparation method thereof

A technology of alumina ceramics and transformers, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc. It can solve problems affecting appearance and service life, deformation of ceramic skeleton products, and lower pass rate of finished products, so as to maintain stability And the effects of uniformity, improving pass rate, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

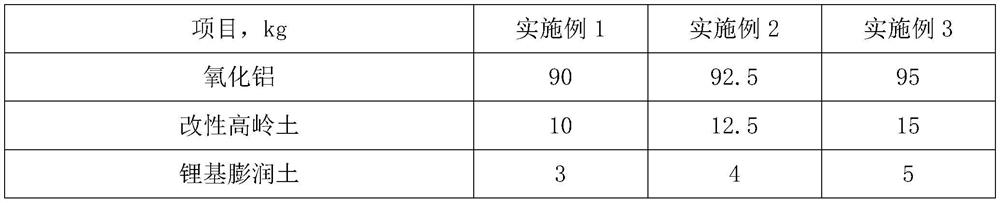

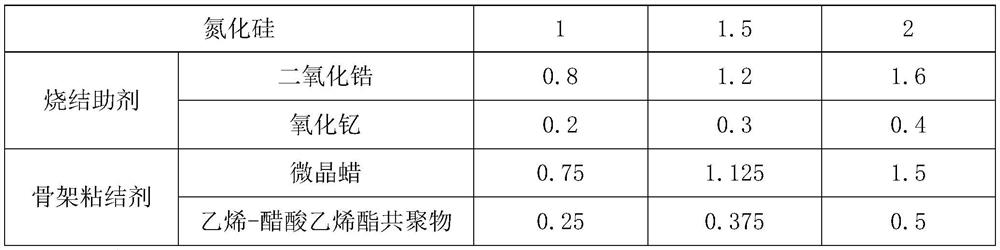

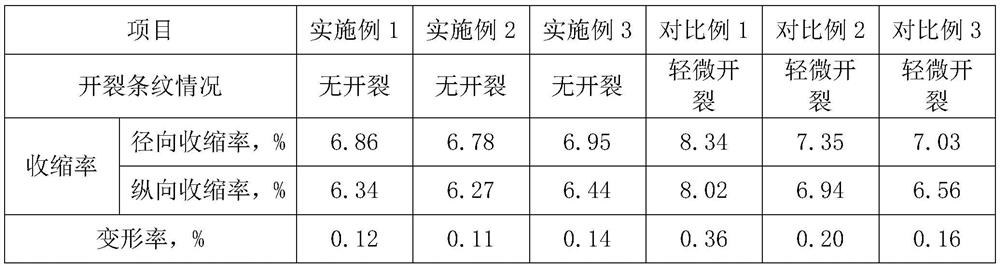

Examples

preparation example 1

[0029] Preparation Example 1: Get 20kg of kaolin, add 40kg of nitric acid solution with a volume fraction of 2%, stir for 6 hours, wash it with ethanol solution to obtain acidified kaolin; add 3kg of magnesia and 1kg of stearic acid to the acidified kaolin, Wet ball milling in a ball mill with ethanol solution as solvent for 6 hours to obtain the mixture; place the mixture at a temperature of 130°C, dry it for 6 hours, then place it at a temperature of 800°C and calcinate for 3 hours to obtain modified kaolin .

preparation example 2

[0030] Preparation Example 2: Take 25kg of kaolin, add 45kg of nitric acid solution with a volume fraction of 2%, stir for 7 hours, and wash it with ethanol solution to obtain acidified kaolin; add 4kg of magnesia and 1.5kg of stearic acid to the acidified kaolin , wet ball milling in a ball mill using ethanol solution as a solvent for 7 hours to obtain a mixture; place the mixture at a temperature of 140°C and dry it for 7 hours, then place it at a temperature of 850°C and calcinate for 3.5 hours to obtain a modified Sexual kaolin.

preparation example 3

[0031] Preparation example 3: get 30kg of kaolin, add 50kg of nitric acid solution with a volume fraction of 2% therein, after stirring for 8h, wash it with ethanol solution to obtain acidified kaolin; add 5kg of magnesia and 2kg of stearic acid to the acidified kaolin, Wet ball milling in a ball mill using ethanol solution as a solvent for 8 hours to obtain a mixture; place the mixture at a temperature of 150°C and dry it for 8 hours, then place it at a temperature of 900°C and calcinate it for 4 hours to obtain a modified kaolin .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com